Hydrocarbon oil hydrogenation technique

A hydrocarbon oil and process technology, which is applied in the field of hydrocarbon oil hydrogenation, can solve the problems of reducing the mass transfer and reaction speed of fresh feed oil and hydrogen, and achieve the effects of reducing the volume of the reactor, low operating costs, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

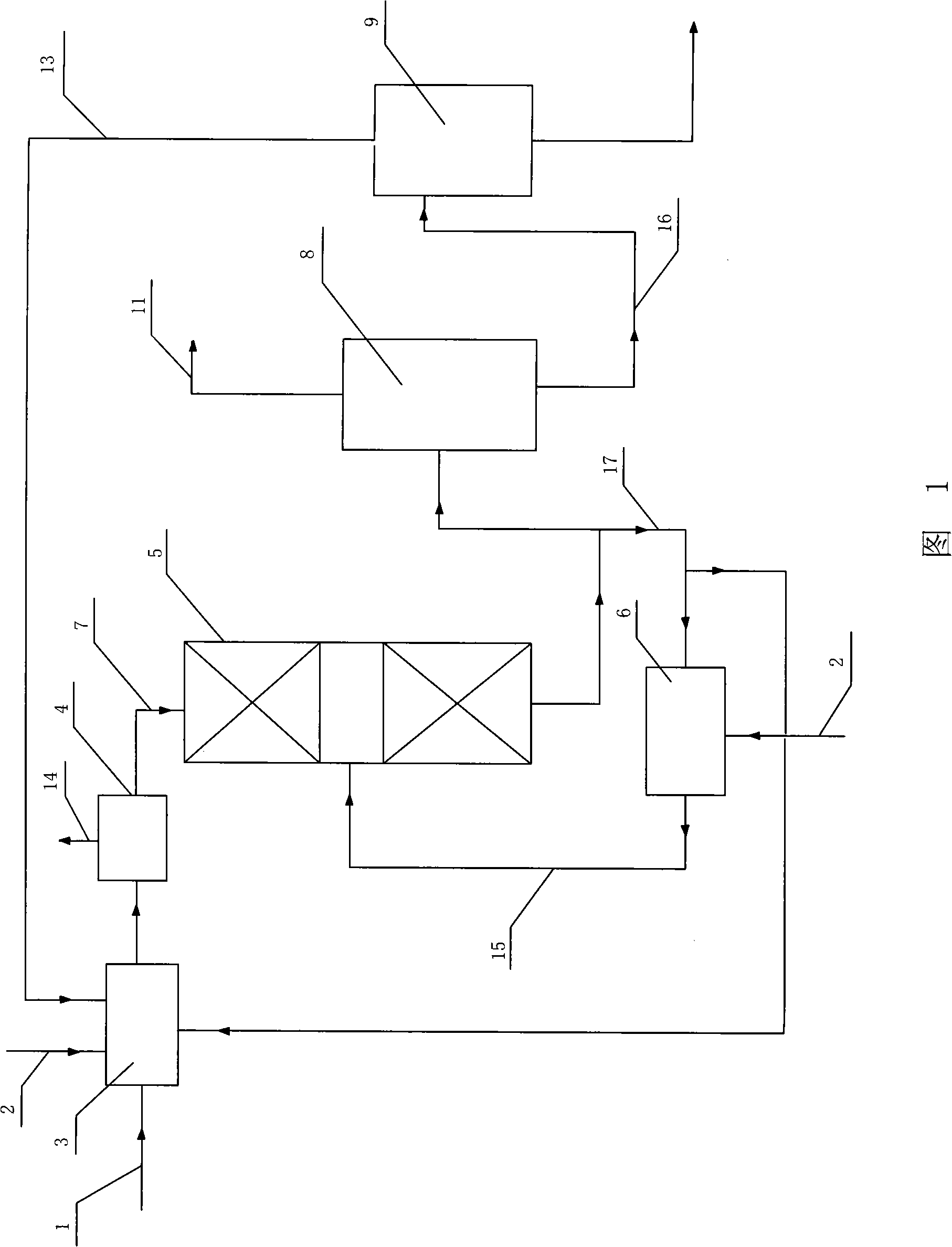

[0071] As shown in Figure 1, the reactor shown in the figure is a two-stage catalyst bed. Fresh raw oil 1 is mixed with hydrogen gas 2 and part of circulating oil in the first mixer 3 in the presence of a solvent or diluent 13, and the mixture flows into the separation tank 4, and the waste gas 14 of the separation tank is separated to become the reactor feed 7, and the reaction The reactor feed 7 enters the catalyst bed in the first stage of the reactor from the upper part of the reactor 5 to contact and react with the catalyst, and another part or all of the circulating oil is mixed with the hydrogen 2 in the second mixer 6 to form the hydrogen-dissolving circulation oil 15, and the hydrogen-dissolving circulation The oil 15 enters the reactor 5 from between the catalyst bed of the first stage and the second stage of the reactor 5, and the reaction effluent from the lower part of the reactor 5 is divided into two parts, one part is used as circulating oil 17, and the other pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com