Composite coal hydrogenation oil refining reactor and oil refining method

A reactor and coal hydrogenation technology, applied in the preparation of liquid hydrocarbon mixture, petroleum industry, gasification process, etc., can solve the problems of high cost, environmental pollution, high resource consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

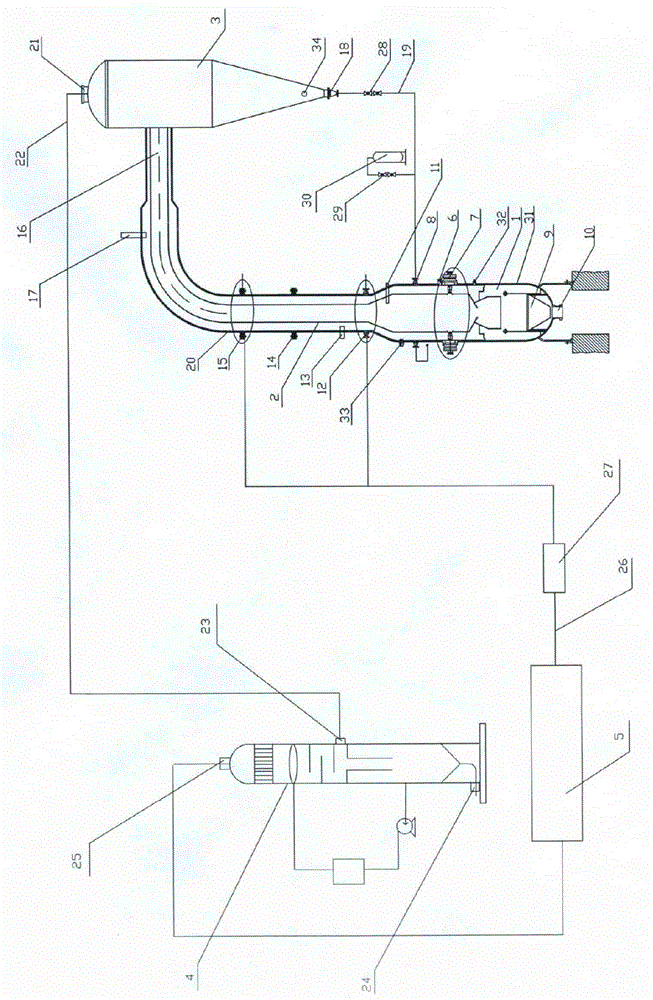

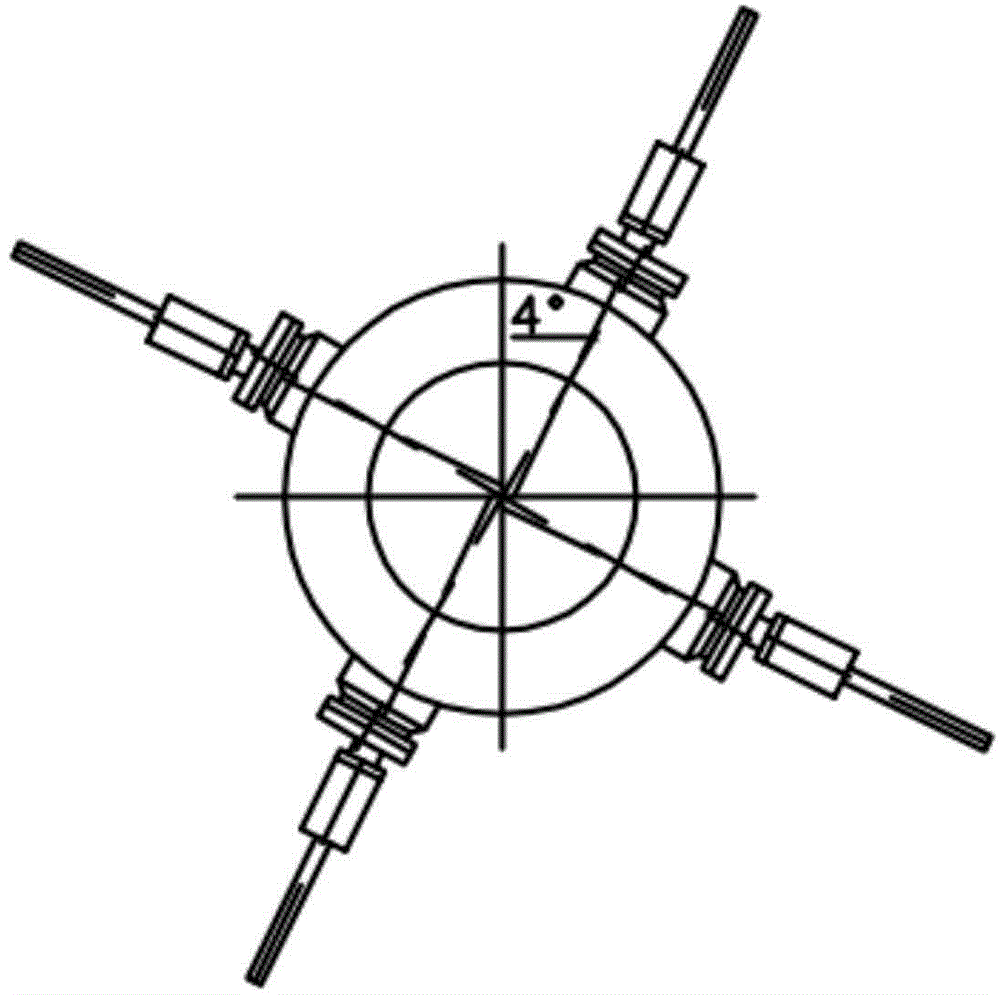

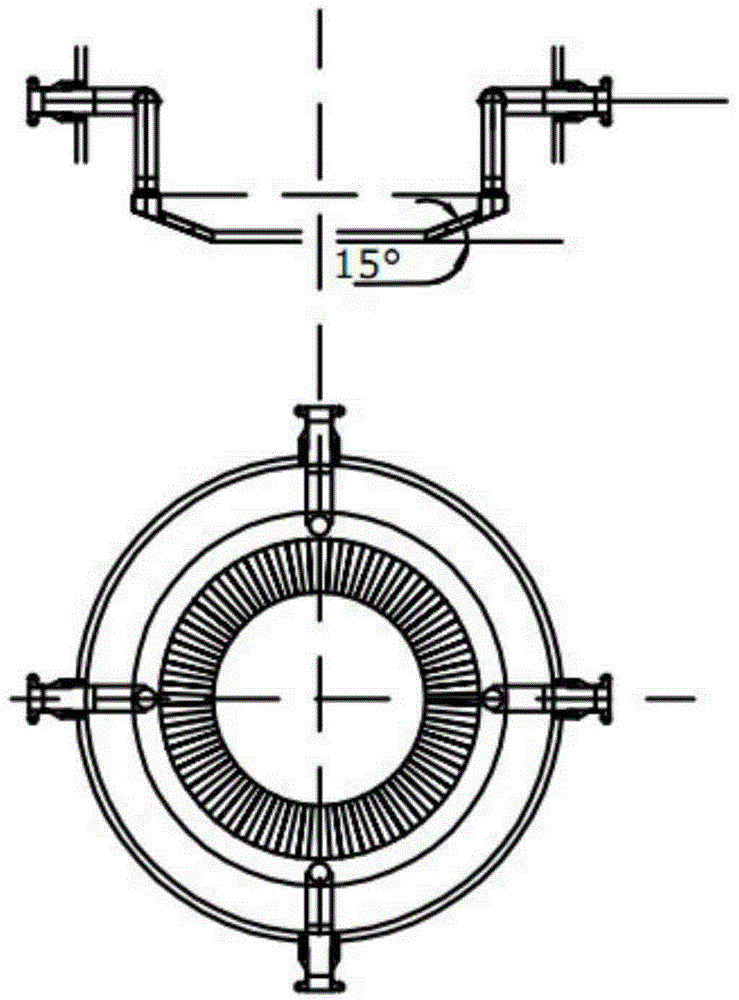

[0019] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a composite coal hydrogenation refinery reactor of the present invention includes a gasifier 1, a reactor 2, a high-temperature cyclone separator 3, an oil-gas separation tower 4 and a carbon monoxide conversion system 5, and in the gasifier 1 There is an integrated start-up burner 6 in the middle, and four coal burners 7 are arranged in the middle and lower part of the gasifier 1. The four coal burners 7 are on the same horizontal plane and are evenly distributed along the circumference of the gasifier 1. 1 is provided with four semi-coke inlets 8, the four semi-coke inlets 8 are on the same horizontal plane and evenly distributed along the circumference of the gasifier 1, and a slag collector 9 is provided at the bottom of the gasifier 1, and the slag collector 9 The slag outlet 10 extends to the outside of the gasifier 1, a pressure sensor 11 is provided at the middle and upper part of the gasifier 1...

Embodiment 2

[0021] A method of oil refining comprises the steps of:

[0022] (1) Oxygen and diesel oil enter from the integrated start-up burner 6, the flow rate of diesel oil is 0.3-1.0Kg / s, the flow rate of oxygen is 0.2-0.5kg / s, and the ignition is carried out through the igniter on the integrated start-up burner 6 , when the temperature in the gasifier 1 reaches 800-1000°C and the pressure reaches 0.6-1.0 MPa, start to add coal powder and oxygen;

[0023] (2) When adding pulverized coal and oxygen, first add through the coal burner 7 next to the integrated start-up burner, and then add through the coal burner 7 facing the already added coal burner. The integrated start-up burner for the combustion of pulverized coal exits. After the integrated start-up burner exits, the other coal burners 7 continue to be added one after another. 1.00kg / s;

[0024] (3) When the temperature in the gasifier rises to 1450-1650°C and the pressure rises to 3.2-3.6Mpa, the pulverized coal gasification react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com