Vehicle mounted hydrogen producing hydrogenation station

A hydrogen refueling station and hydrogen technology, applied in the field of hydrogen production and refueling stations, can solve the problems of continuous supply of hydrogen, going back and forth between the hydrogen production station and the hydrogen refueling point, and large investment in the hydrogen refueling station.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

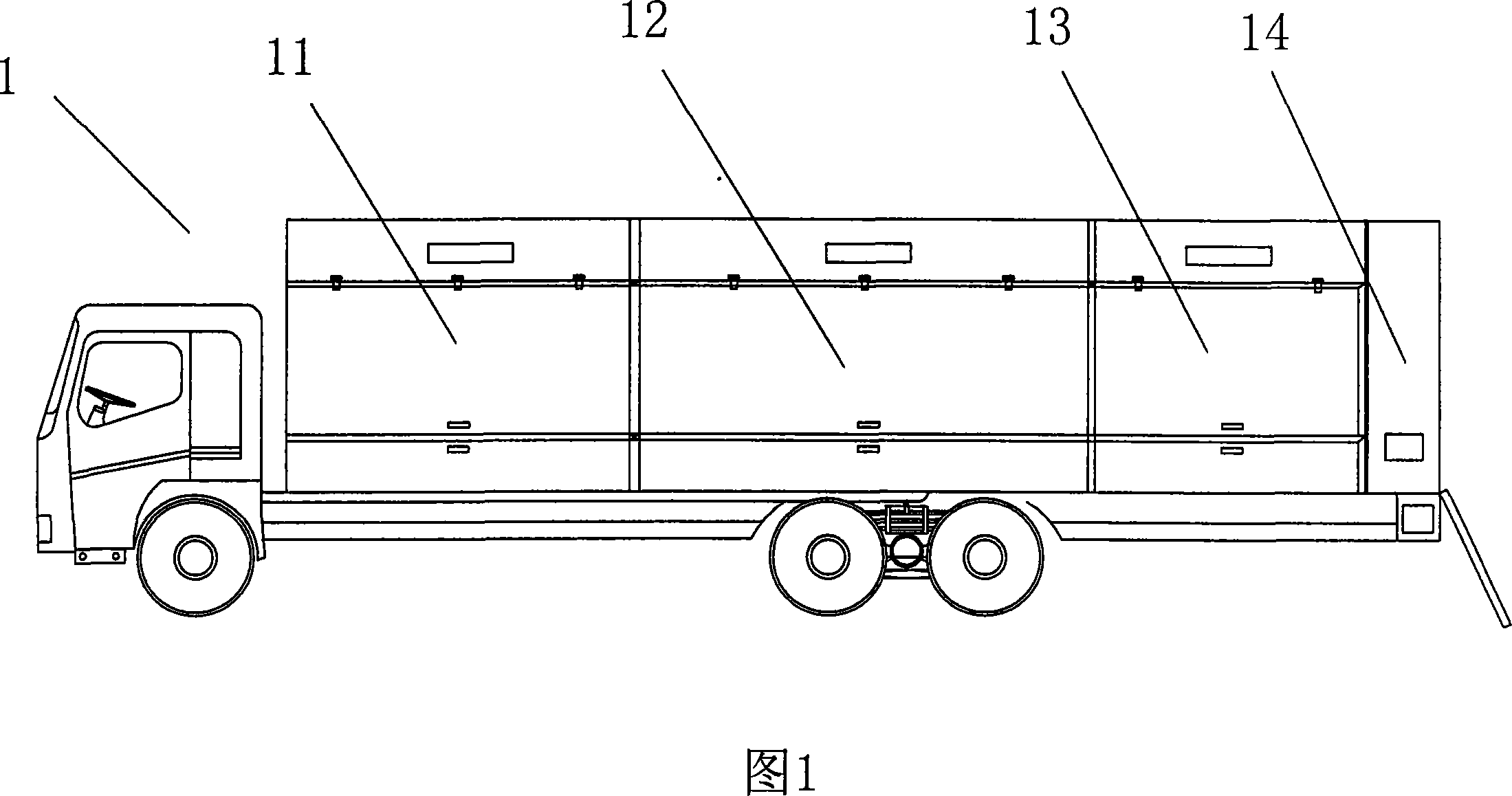

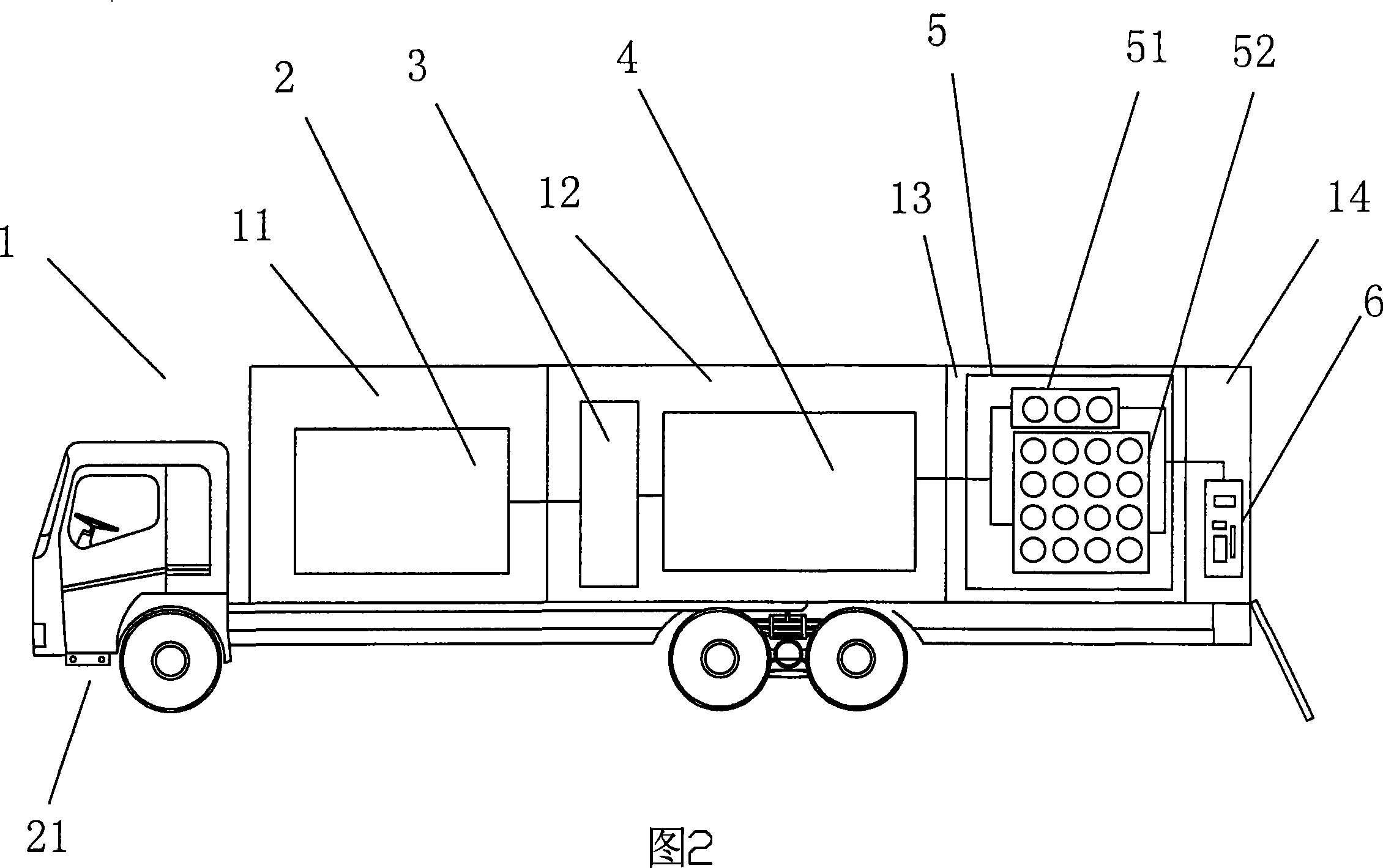

[0017] As shown in Figure 1, it is a schematic structural diagram of the vehicle-mounted hydrogen production and refueling station of the present invention, which includes a special transport vehicle 1, a compact water electrolysis device 2, a low-pressure hydrogen storage tank group 3, a special hydrogen compressor 4, and a high-pressure hydrogen storage tank Group 5 and hydrogen gas vending machine 6, and the compressed water electrolysis equipment 2, low pressure hydrogen storage tank group 3, special hydrogen compressor 4, medium pressure hydrogen storage tank, high pressure hydrogen storage tank group 5 and hydrogen gas vending machine 6 are all electrically connected with a control system.

[0018] The special transport vehicle 1 is refitted from the Auman heavy-duty vehicle of BAIC Group Corporation, the model is BJ1258VMJP, and its load can meet the needs of the total weight (about 20 tons) of the hydrogen production and refueling station equipment of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com