LED packaging structure and packaging method

A technology of LED encapsulation and encapsulation colloid, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of difficulty in controlling the ink color consistency of the LED module shell, affecting the appearance of the LED display device, and the high rate of defective packaging structures. Save the high temperature welding process, save the amount of packaging glue, and facilitate the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

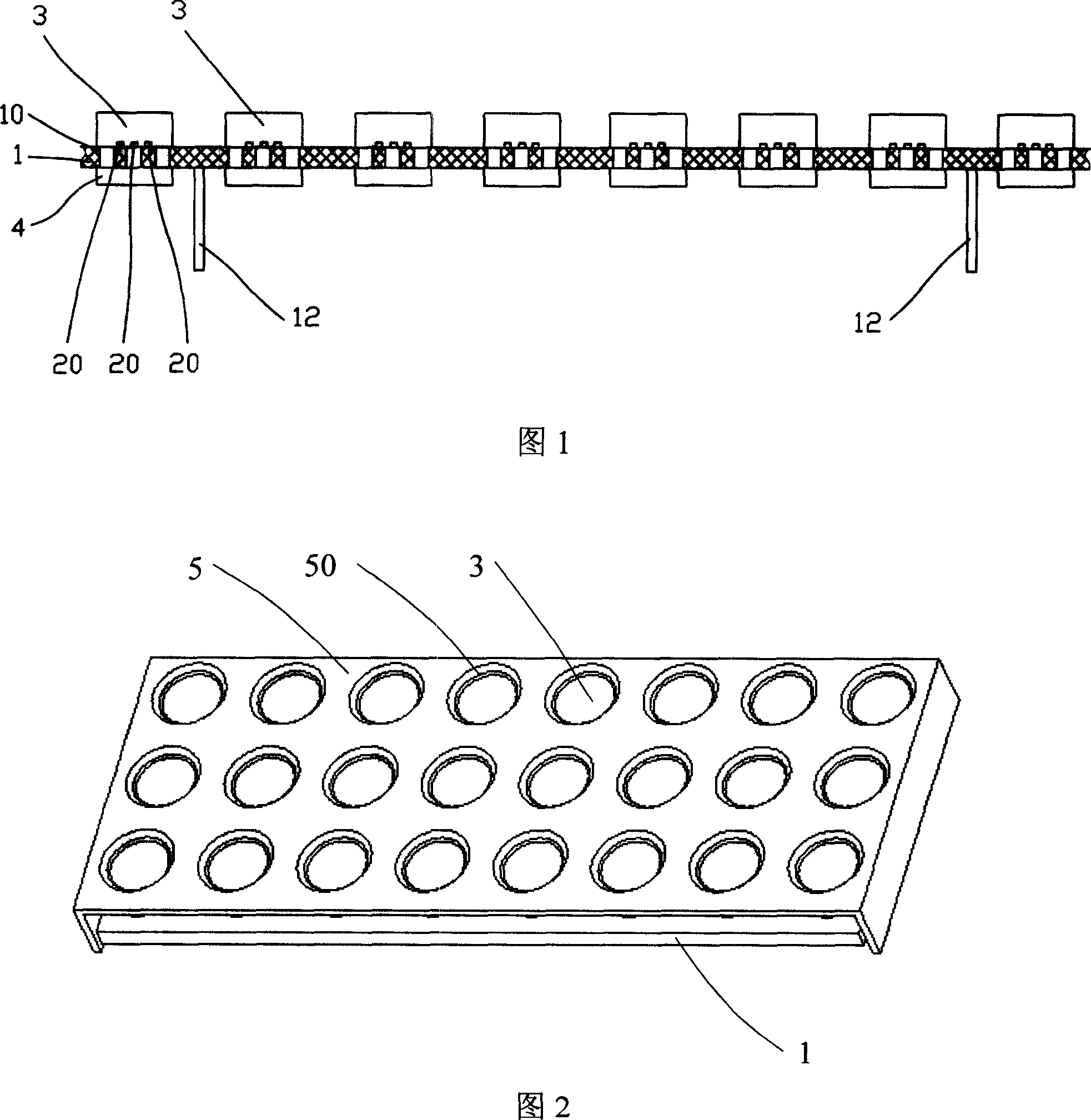

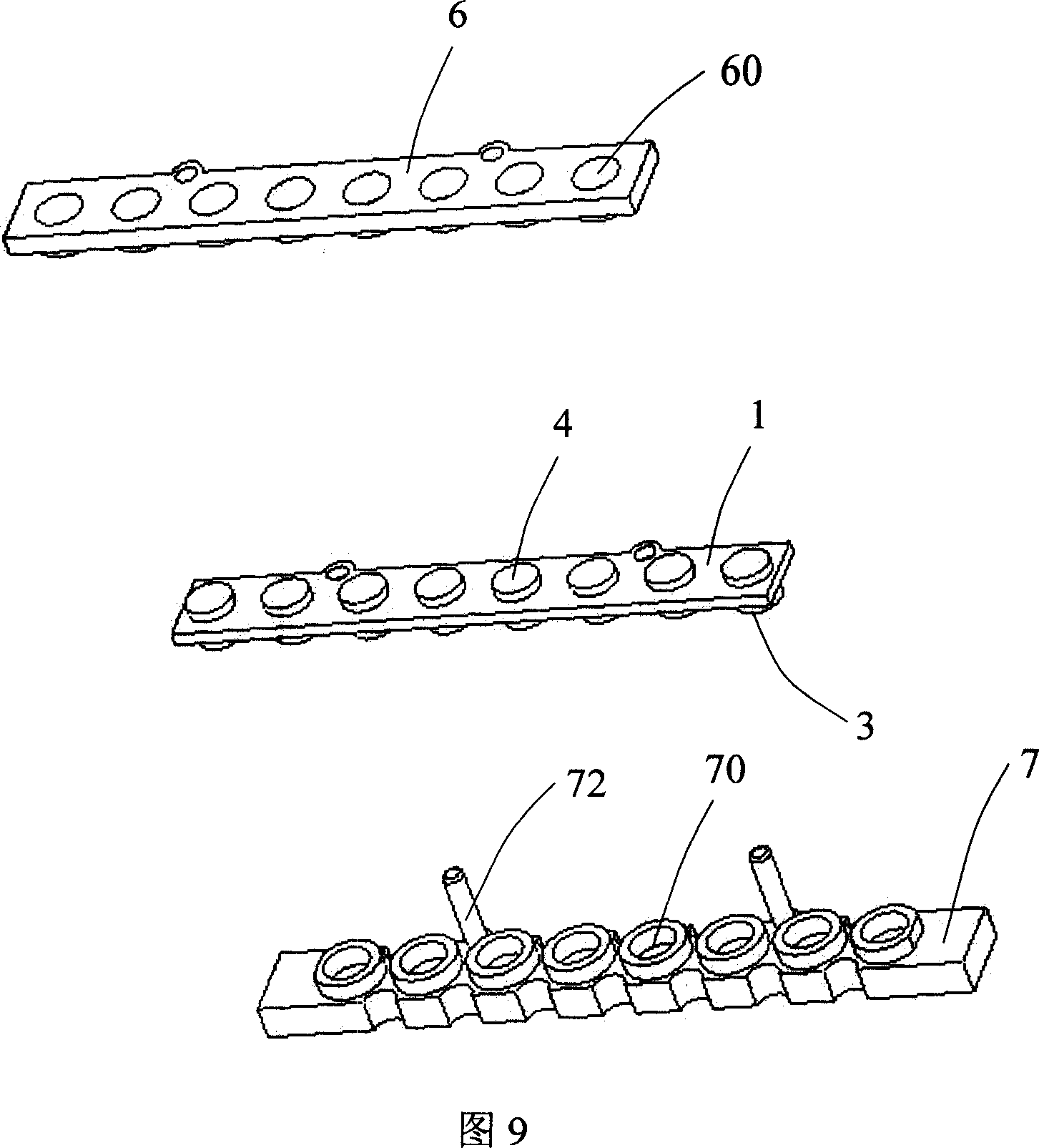

[0040] As shown in FIG. 1 , the present invention provides an LED packaging structure, which includes a circuit board 1 , several LED light emitting units, packaging colloid 3 and fixing colloid 4 .

[0041] Wherein, the front of the circuit board 1 is preset with several bonding positions for bonding LED light-emitting chips thereon. On the circuit board 1, there is at least one glue hole 10 penetrating through the circuit board 1 in each LED light-emitting unit, which can not only be used for glue during packaging, but also for wiring; the back of the circuit board 1 is provided with a port 12 connected to an external circuit , in the embodiment shown in the figure, the port 12 is a port in the form of pins.

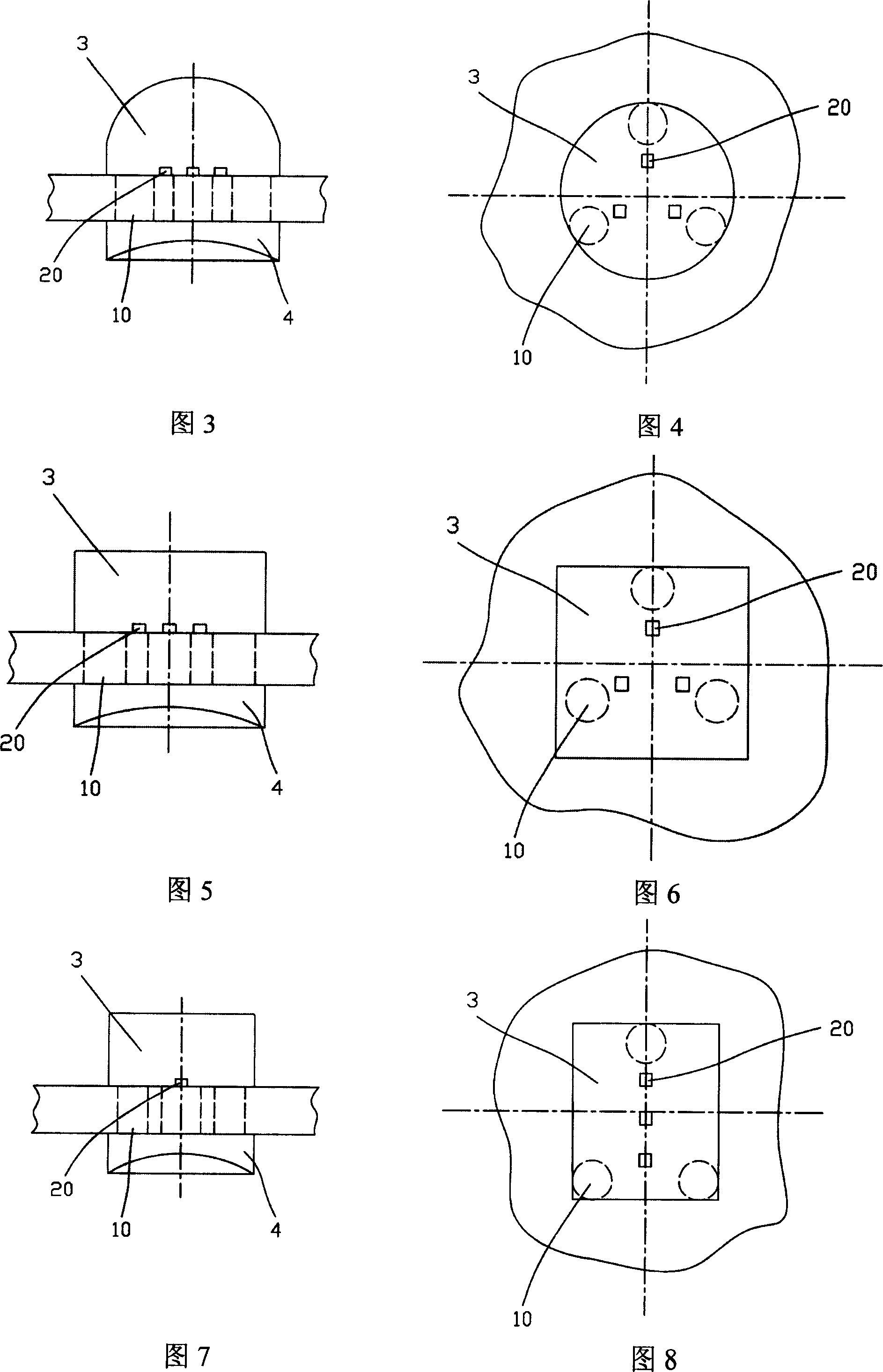

[0042] As shown in Figure 2, the front side of the circuit board 1 is also equipped with a mask 5, and the mask 5 is provided with through holes 50 corresponding to each LED light emitting unit so that each LED light emitting unit is exposed from the corresponding thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com