Method for preparing monodisperse titanium dioxide (B) nano particles

A technology of titanium dioxide and nano-particles, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems that have not been reported in relevant literature, reduce post-processing costs, simple and easy process, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a 250ml round bottom flask, add 50ml of ethylene glycol, add 2ml of titanium tetrachloride under nitrogen protection, heat up to 200°C, add 3ml of deionized water, reflux for 2 minutes, and use the product (transparent solution) after reflux reaction The reaction was quickly stopped by cooling in a cold water bath, and acetone 3 times the volume of the reaction system was added dropwise with stirring, then the stirring was stopped, and the mixture was allowed to settle for 10 minutes. The resulting product was washed, centrifuged and dried.

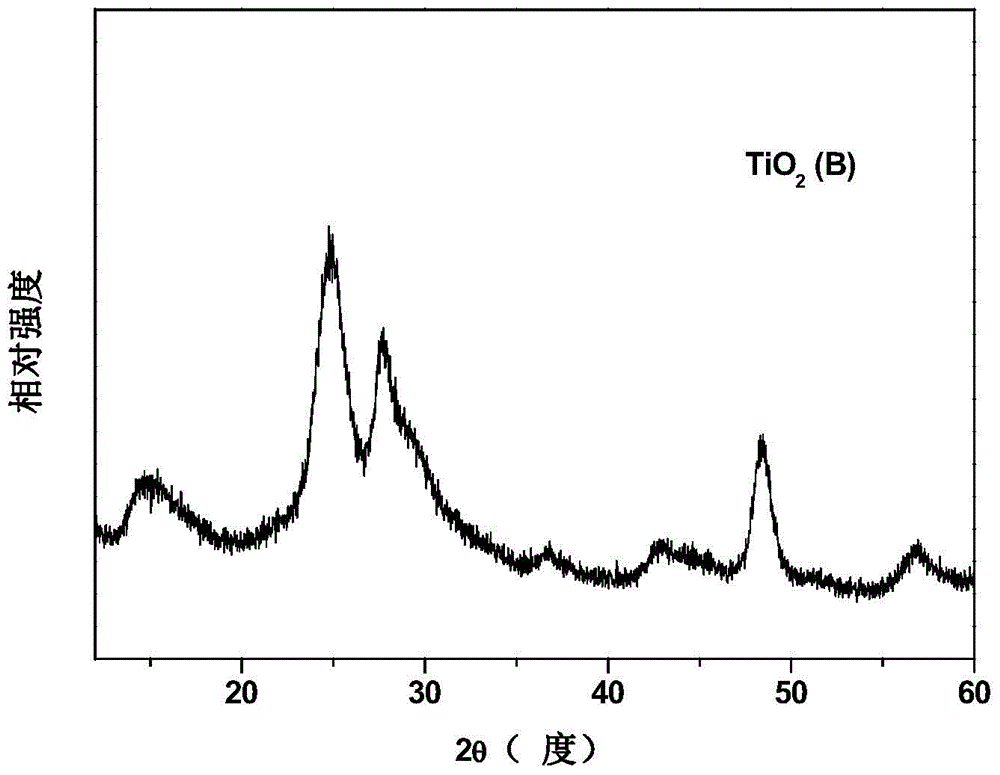

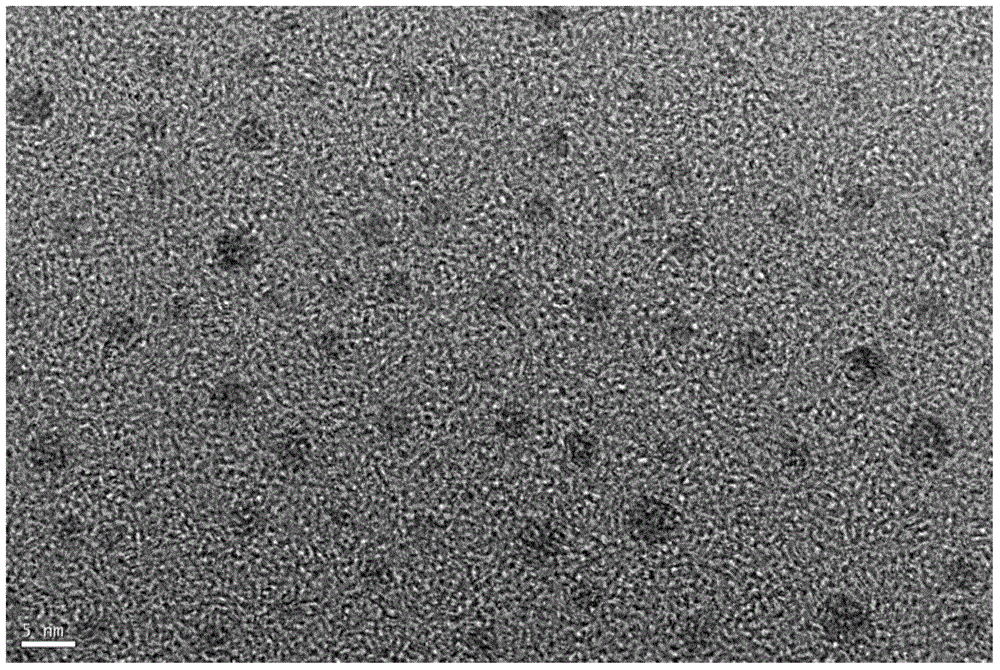

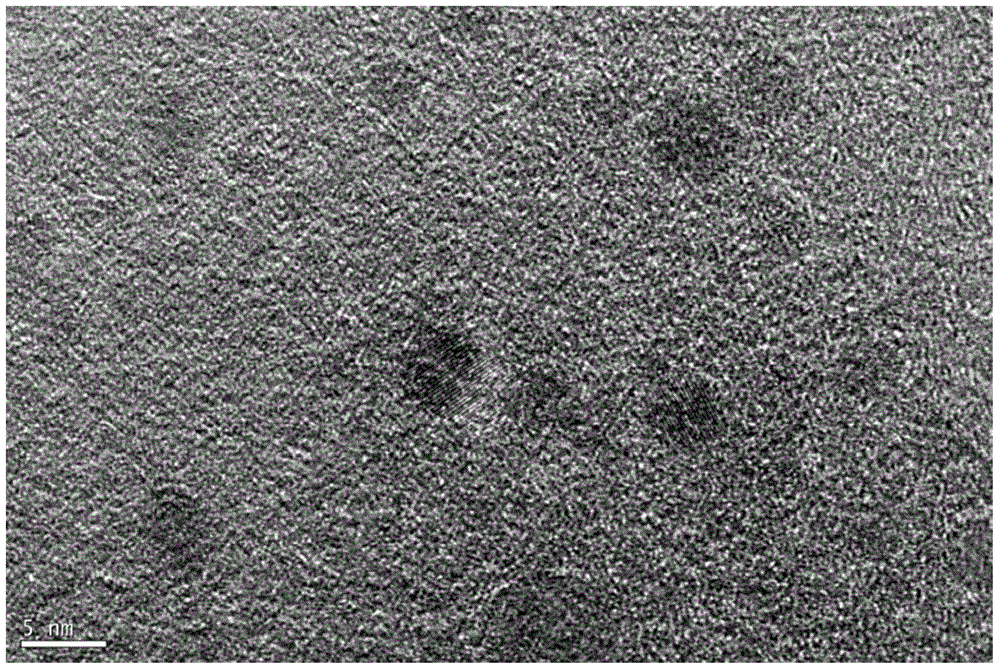

[0029] This embodiment is the best embodiment. Figure 1 ~ Figure 3 The TiO obtained in this embodiment is given respectively 2 - X-ray diffraction spectrum, transmission electron microscope pictures, and high-resolution transmission electron microscope pictures of B nanoparticles. The obtained product is monodisperse monoclinic phase titanium dioxide nanoparticles with a particle diameter of 2-5 nm.

Embodiment 2

[0031] In a 250ml round bottom flask, add 50ml of ethylene glycol, add 2ml of titanium tetrachloride under the protection of nitrogen, raise the temperature to 160°C under the protection of nitrogen, add 3ml of deionized water, reflux for 2 minutes, and reflux the product after reaction (Transparent solution) Stop the reaction by cooling in a cold water bath, dropwise add acetone 3 times the volume of the reaction system under stirring, stop stirring, and settle for 10 minutes. The resulting product was washed, centrifuged and dried.

[0032] Compared with Example 1, in this example, the reaction temperature is changed to 160° C., and the resulting product is monodisperse monoclinic titanium dioxide nanoparticles, Figure 4 The transmission electron micrograph of the product prepared in this embodiment is given, Figure 5 According to its X-ray diffraction spectrum, the morphology has no obvious change.

Embodiment 3

[0034] In a 250ml round bottom flask, add 50ml of ethylene glycol, add 2ml of titanium tetrachloride under nitrogen protection, heat up to 200°C, add 3ml of deionized water, reflux for 7 minutes, and use the product (transparent solution) after reflux reaction Cool in a cold water bath to stop the reaction, add dropwise acetone 3 times the volume of the reaction system under stirring, stop stirring, and settle for 10 minutes. The resulting product was washed, centrifuged and dried.

[0035] Compared with Example 1, the present embodiment changes the reaction time into 7 minutes, and the resulting product is monodisperse monoclinic titanium dioxide nanoparticles, Figure 6 The transmission electron micrograph of the product prepared in this embodiment is given, Figure 7 According to its X-ray diffraction spectrum, the morphology has no obvious change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com