Peelable nano-grade decontamination coating

A decontamination coating and nanotechnology, which is applied in the field of material chemistry, can solve the problems that the decontamination effect is difficult to achieve the desired effect, has no practical application value, and the surface of the substrate is uneven. Low, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

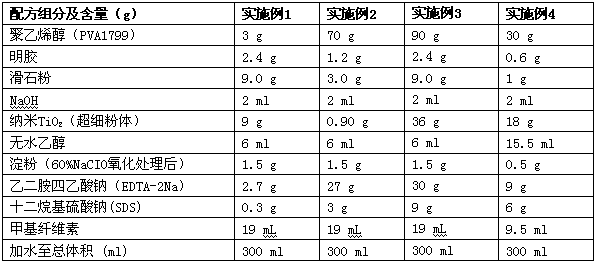

[0064] Strippable nanometer decontamination paint, according to the formula component content indicated in Table 1, each component fully mixes and gets final product.

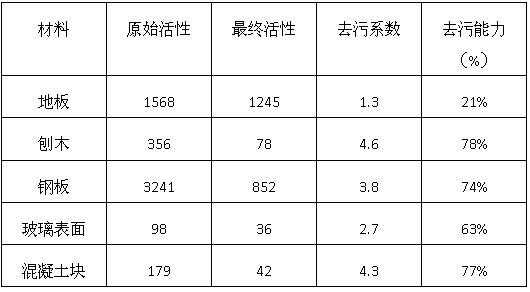

[0065] The strippable nano-scale decontamination coating was coated on a mold conforming to GB / T1040.1.2006 to prepare a polymer film, and the performance of the strippable polymer film decontamination coating was measured. The result is as follows:

[0066] .

Embodiment 2

[0068] Strippable nanometer decontamination paint, according to the formula component content indicated in Table 1, each component fully mixes and gets final product.

Embodiment 3

[0070] Strippable nanometer decontamination paint, according to the formula component content indicated in Table 1, each component fully mixes and gets final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com