Method and device for manufacturing metal additive materials

A metal additive and manufacturing method technology, applied in the field of metal additive manufacturing, can solve problems such as affecting the forming quality of parts, and achieve the effects of improving forming efficiency, ensuring forming quality, and being widely applicable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

[0019] The invention provides a metal additive manufacturing method, which includes building a part structure and a support structure layer by layer; when constructing the support structure, instead of using the traditional method of high-energy beam melting metal powder to form the support structure, an adhesive is used to form the support structure. The support structure is constructed by bonding the metal powder material with an adhesive; after the part is formed, the adhesive is melted or dissolved by high-temperature heating or dissolved in an organic solvent to remove the support structure.

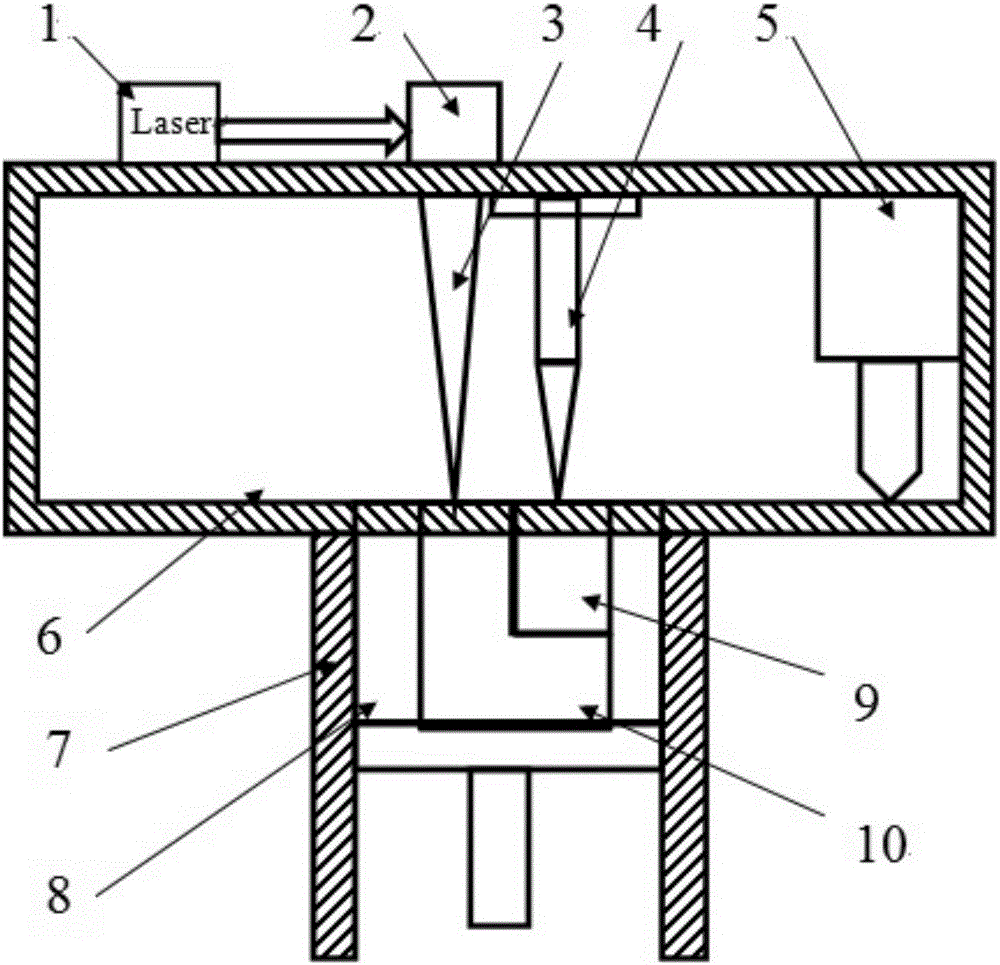

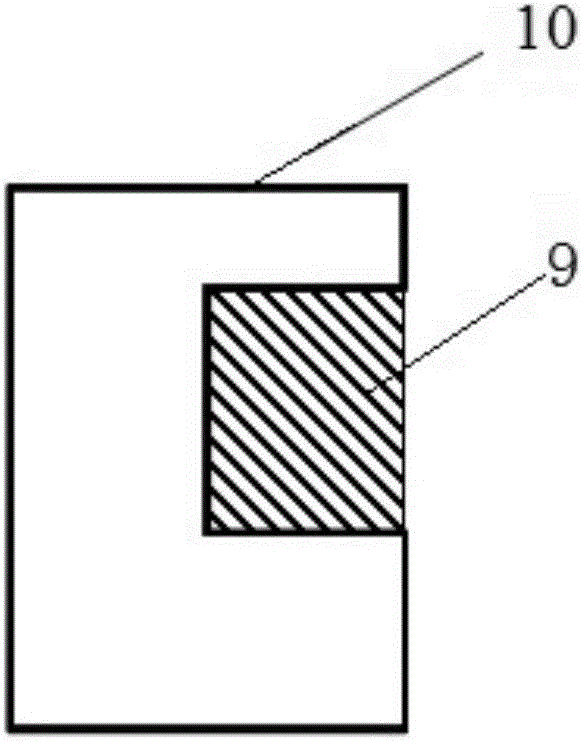

[0020] In order to realize the method, the present invention provides a metal additive manufacturing device, in which a glue spraying device 4 is added to the existing forming ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com