Cleaning device and method of finished oil tank

A technology for cleaning devices and oil tanks, which is applied to cleaning methods and appliances, separation methods, grease/oily substances/floating matter removal devices, etc., which can solve problems such as potential safety hazards, high transportation costs, and long-term work cycles, and achieve Reduce invalid operation time, reduce the amount of clean water, and shorten the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe the present invention below in conjunction with specific embodiment:

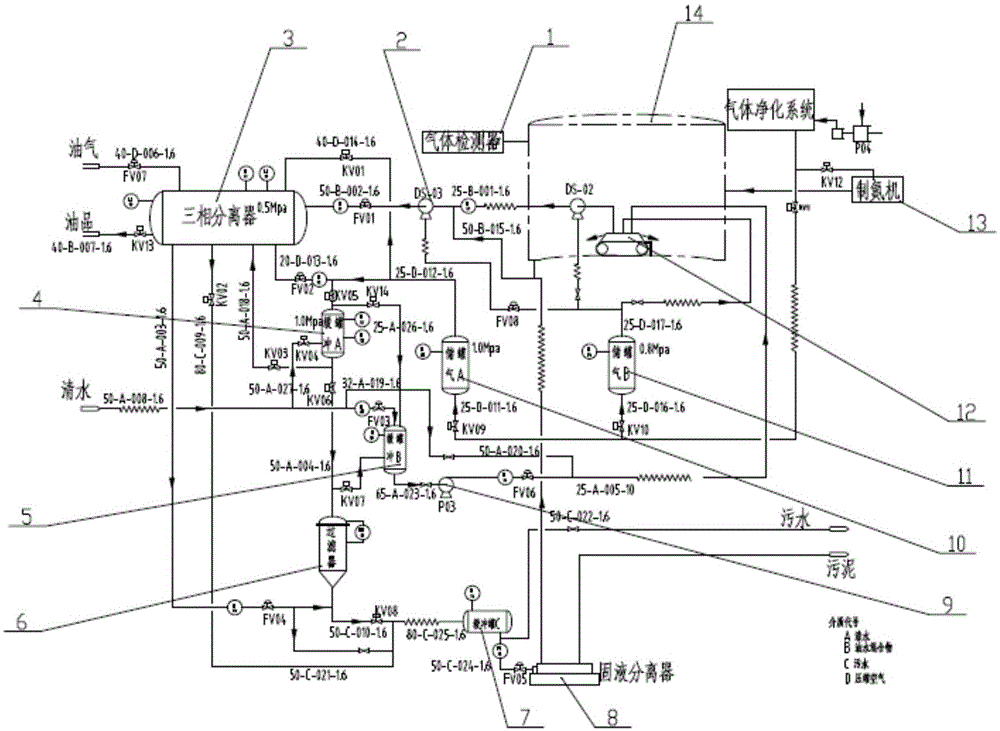

[0022] The function of the system of the present invention is: provide high-pressure water to the cleaning robot through the centrifuge and the cleaning pump, and the cleaning robot moves in the tank to spray the high-pressure water on the tank bottom and the tank wall to realize the cleaning of the storage tank, and the cleaning is generated by the sewage suction pump. After the sewage is firstly separated and filtered by the three-phase separation equipment, the cleaning water enters the filter equipment for secondary filtration, and then is supplied to the robot through the centrifuge and the cleaning pump to realize the circulation of the cleaning medium.

[0023] Refer to attached figure 1 , The product oil tank cleaning device in this embodiment includes a nitrogen production system 13, an oxygen concentration monitoring system 1, a cleaning robot 12, a three-phase separation device 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com