Nano zero-valent iron loaded magnetic nano illite-montmorillonite clay and preparation method and application thereof

A technology of nano-zero-valent iron and Imon clay, which is applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as unfavorable magnetic separation and low precursor preparation efficiency, and achieve Shorten the preparation time, reduce the cost of post-processing, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

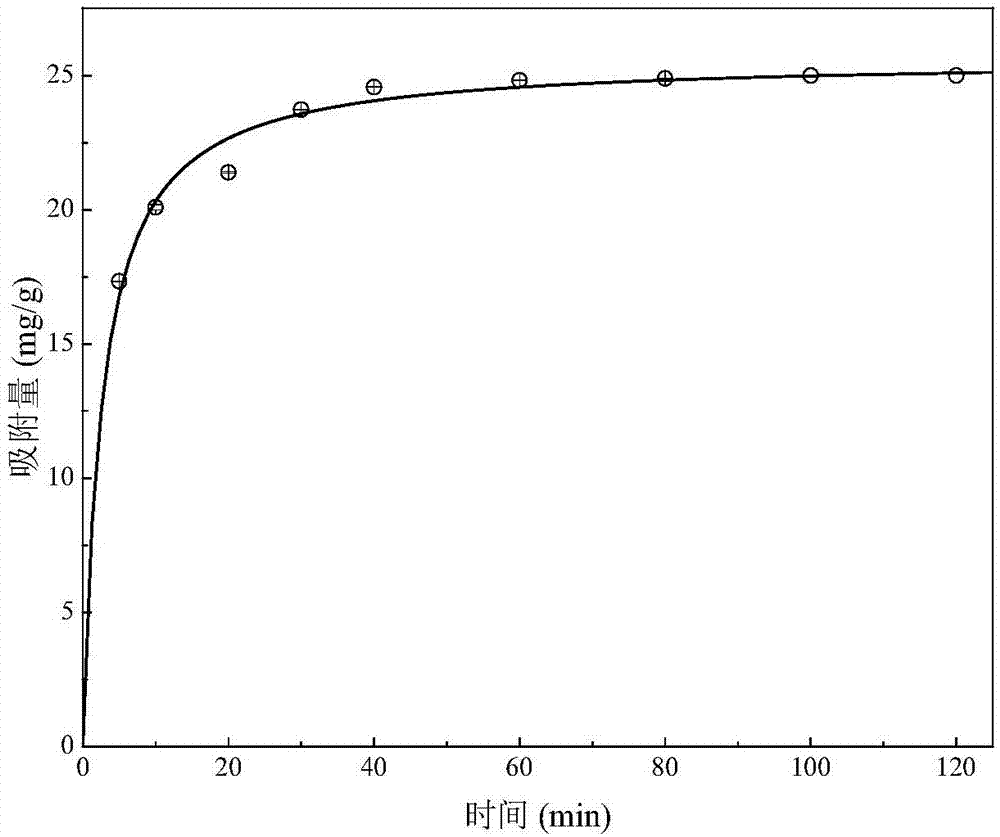

Examples

Embodiment 1

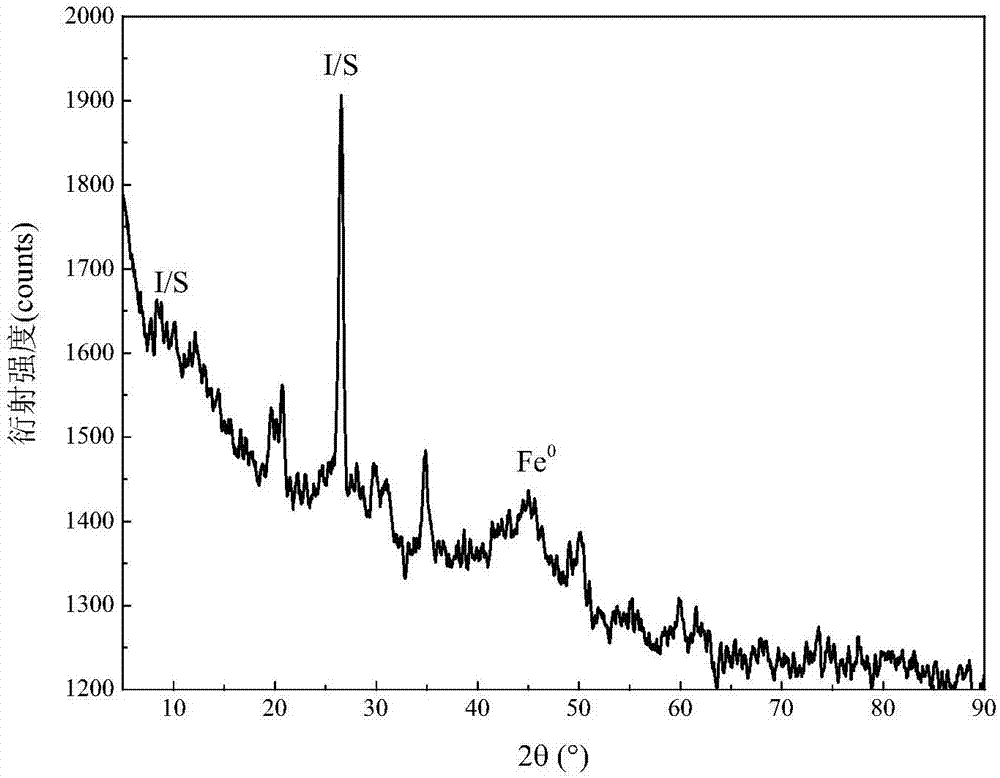

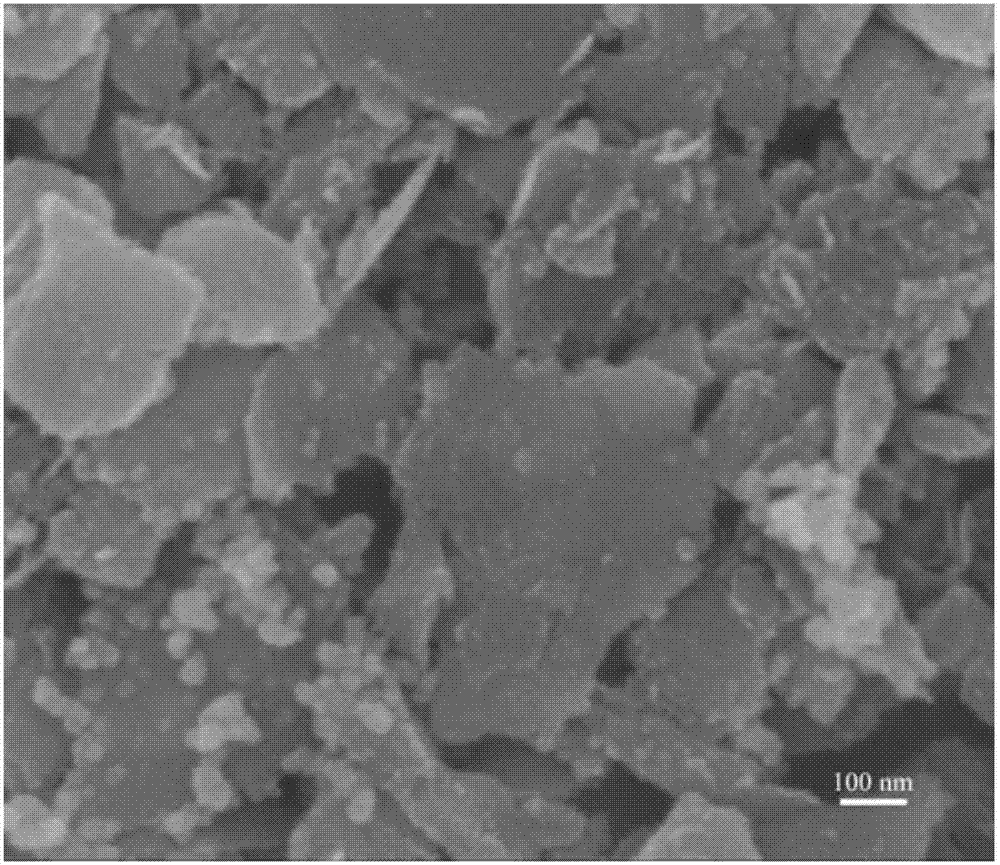

[0034] Preparation of magnetic nano-Imon clay loaded with nano-zero-valent iron:

[0035] (1) Prepare nano-Imon clay slurry with a solid content of about 50wt.% into Imon clay slurry with a solid content of 5wt.%, and then use a vertical high-shear disperser to disperse at 1500r / min for 20 minutes. A stable and uniform nano-Imon clay slurry is formed.

[0036] (2) 160mL of absolute ethanol was added to 40mL of 5wt.% Yimeng clay slurry to prepare 200mL of mixed solution. Weigh ferric chloride hexahydrate (FeCl 3 ·6H 2 O) 4.84g, then added to Yimeng clay suspension. The precursor solution was obtained by stirring for 30 minutes under the assistance of ultrasonic, the ultrasonic power was 150W, and the speed of the stirrer was 300r / min. Nitrogen was introduced for protection during the stirring process.

[0037] (3) Put 2.72g sodium borohydride (NaBH 4 ) Dissolve in 240mL deionized water to make a reducing agent.

[0038] (4) Add dropwise the sodium borohydride solution prepared in st...

Embodiment 2

[0049] To prepare magnetic nano-Imon clay loaded with nano-zero-valent iron:

[0050] (1) Prepare the nano-Imon clay slurry with a solid content of about 45wt.% into an Imon clay slurry with a solid content of 2wt.%, and then use a vertical high-shear disperser to disperse at 500r / min for 30 minutes to form Stable and uniform nano-Imon clay slurry.

[0051] (2) Add 100 mL of absolute ethanol to 100 mL of 2wt.% Yimeng clay slurry to prepare 200 mL of mixed solution. Weigh ferric chloride hexahydrate (FeCl 3 ·6H 2 O) 4.84g, then added to Yimeng clay suspension. The precursor solution was obtained by stirring for 30 minutes under the assistance of ultrasonic, the ultrasonic power was 100W, and the speed of the stirrer was 500r / min. Nitrogen was introduced for protection during the stirring process.

[0052] (3) Put 2.72g sodium borohydride (NaBH 4 ) Dissolve in 120mL deionized water to make a reducing agent.

[0053] (4) Add dropwise the sodium borohydride solution prepared in step (3...

Embodiment 3

[0056] To prepare magnetic nano-Imon clay loaded with nano-zero-valent iron:

[0057] (1) Prepare the nano-Imon clay slurry with a solid content of about 45wt.% into an Imon clay slurry with a solid content of 10wt.%, and then use a vertical high-shear disperser to disperse at 1000r / min for 60min to form Stable and uniform nano-Imon clay slurry.

[0058] (2) Add 160 mL of absolute ethanol to 40 mL of 10 wt.% Yimeng clay slurry to prepare 200 mL of mixed solution. Weigh ferric chloride hexahydrate (FeCl 3 ·6H 2 O) 9.68g, and then added to Yimeng clay suspension. The precursor solution was obtained by stirring for 60 minutes under the assistance of ultrasonic, the ultrasonic power was 250W, and the speed of the stirrer was 500r / min. Nitrogen was introduced for protection during the stirring process.

[0059] (3) Put 6.72g sodium borohydride (NaBH 4 ) Dissolve in 240mL deionized water to make a reducing agent.

[0060] (4) Add dropwise the sodium borohydride solution prepared in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com