Method for producing marsh gas through mixed anaerobic fermentation of blue algae and sludge

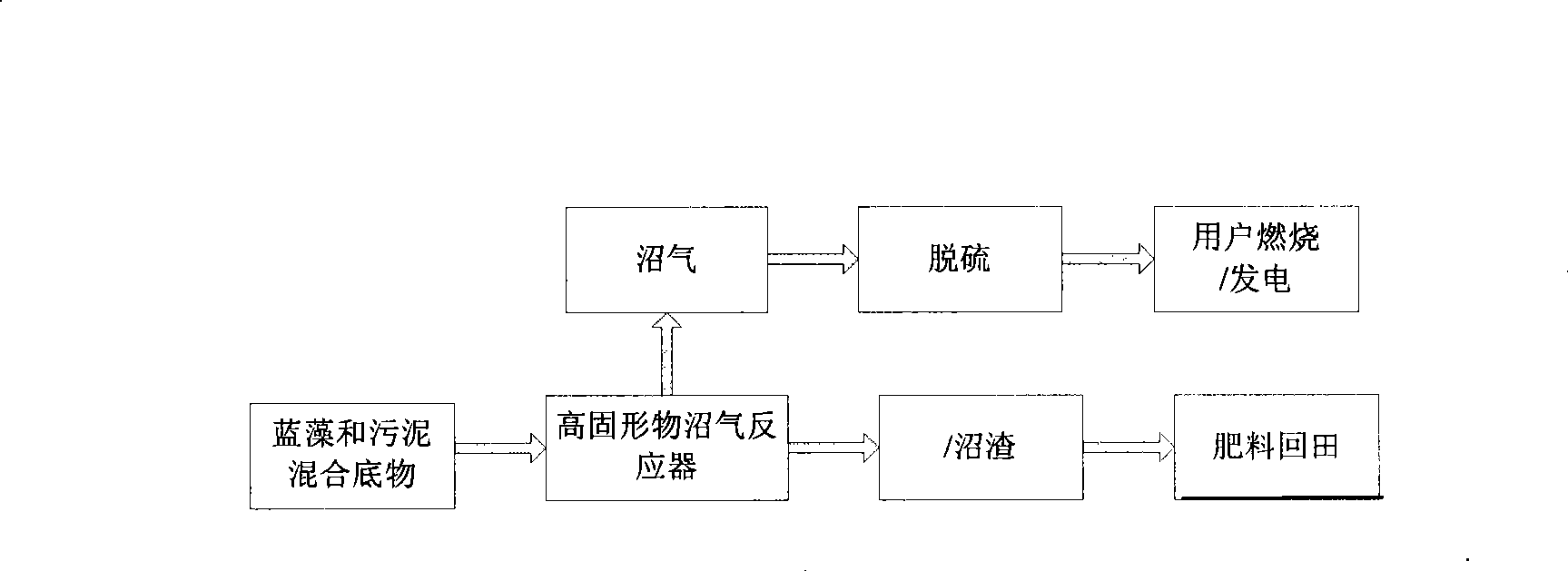

A technology for anaerobic fermentation and biogas production, applied in microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve problems that are not necessarily scientific, and the digestion rules are not clear, so as to facilitate the expansion of production and the gas output rate. High, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

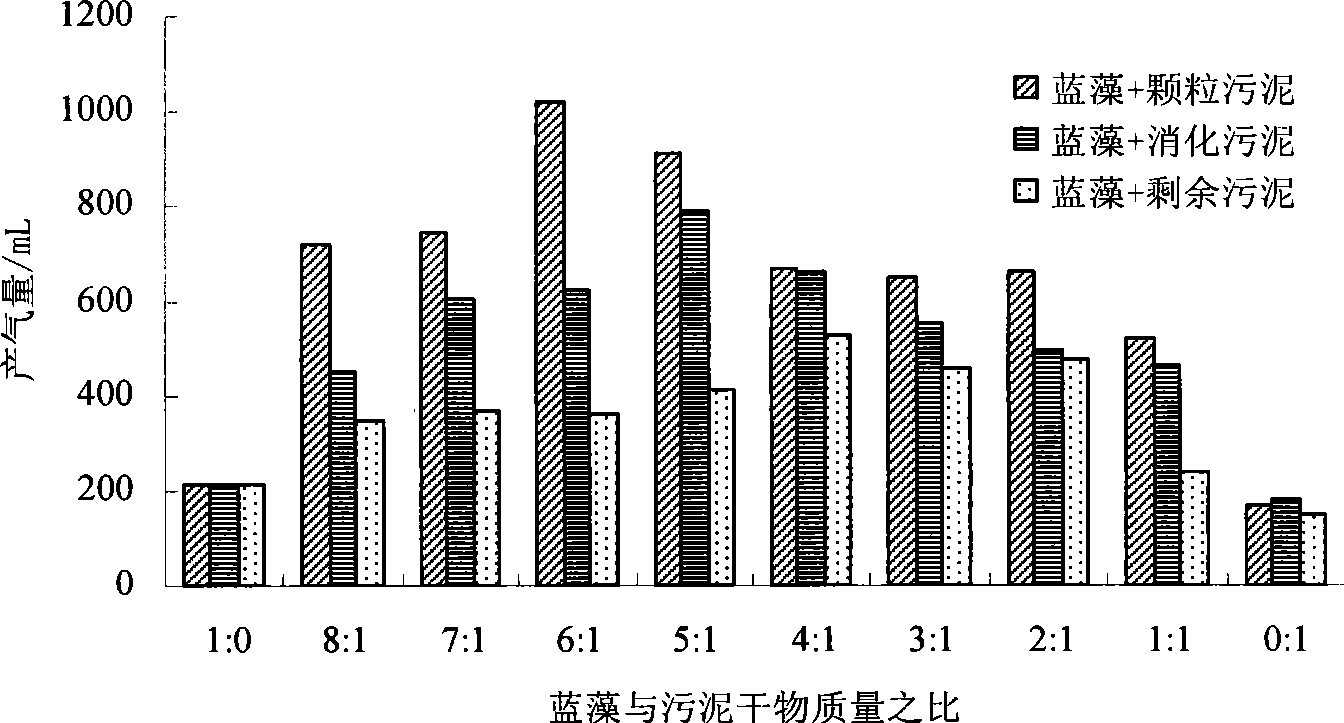

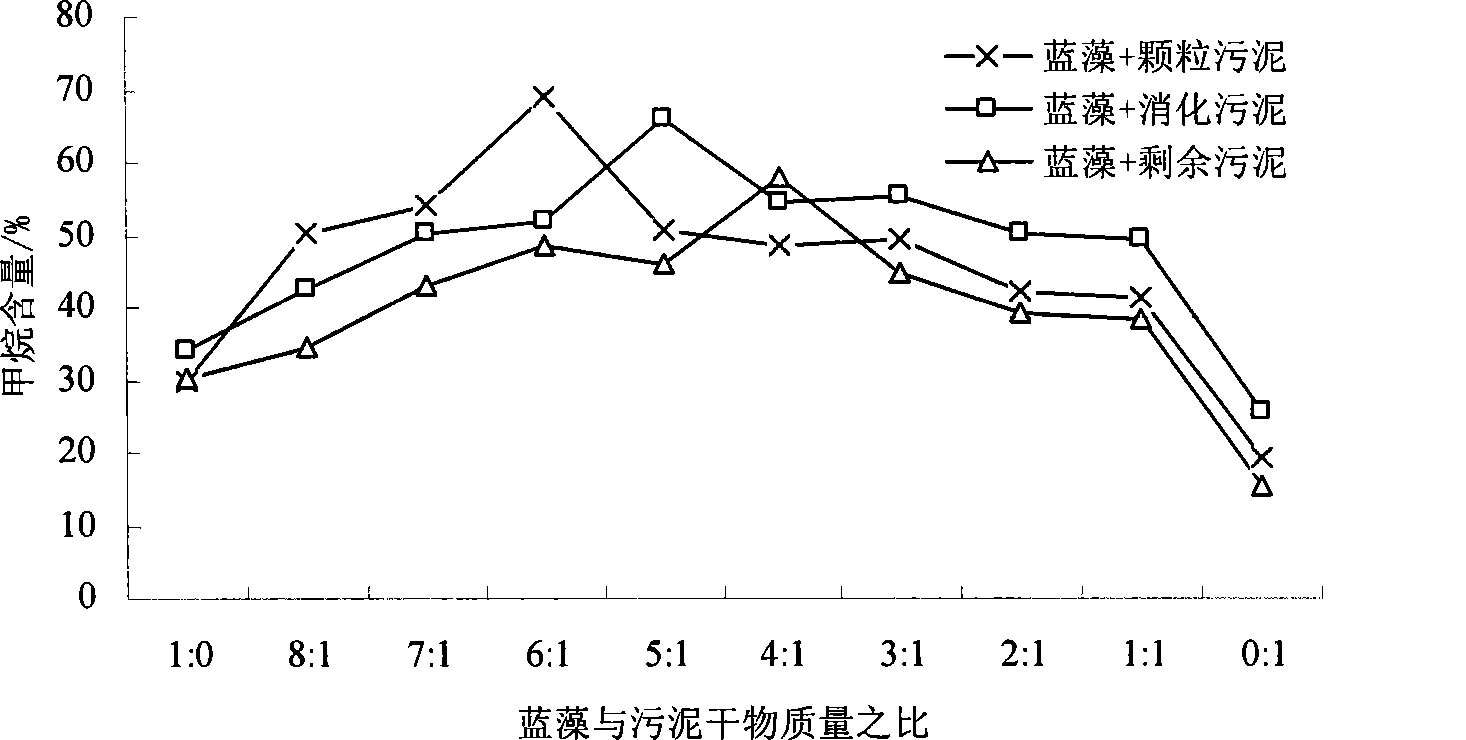

[0024] Example 1: Effects of different material ratios of cyanobacteria and sludge on the output of anaerobic fermentation methane

[0025] During the biogas fermentation process, choosing an appropriate material ratio can maximize the digestion of cyanobacteria and improve the utilization rate of cyanobacteria; on the other hand, it can greatly reduce the remaining biogas residue in the fermentation process and effectively reduce the secondary pollution to the environment.

[0026] figure 2 , image 3 They are the cumulative gas production and methane content of anaerobic fermentation of cyanobacteria, granular sludge, digested sludge, and excess sludge according to different material ratios. It can be seen from the figure that when the dry matter ratio of cyanobacteria to granular sludge, digested sludge, and residual sludge is 5-6:1, 5:1, and 4:1, respectively, the gas production and methane content reach the highest. The same sludge and cyanobacteria are mixed in differ...

Embodiment 2

[0028] Example 2: Changes in algae toxin content in the mixed anaerobic fermentation of cyanobacteria and sludge to produce biogas

[0029] The degradation of algal toxins is the key to solving the problem of cyanobacteria. The degradation of algal toxins is very slow in the natural storage state. According to literature reports, after 3 months of natural storage of cyanobacteria in Taihu Lake, the algal toxin MC-RR and MC-LR are still as high as 38 μg / kg and 120 μg / kg, far exceeding the drinking water standard. The contents of cyanotoxins were measured before and after anaerobic fermentation of cyanobacteria, and the data are shown in Table 1.

[0030] Table 1 Changes of algal toxins in mixed anaerobic fermentation of cyanobacteria and sludge

[0031]

[0032] It can be seen from Table 1 that the contents of algal toxins in the mixed anaerobic fermentation groups of cyanobacteria, granular sludge, digested sludge, and excess sludge before fermentation were 366 μg / L, 356 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com