Monatomic iron nitrogen-doped porous carbon catalyst as well as preparation method and application thereof

A catalyst and porous carbon technology, applied in the field of monoatomic iron nitrogen-doped porous carbon catalyst and its preparation, can solve the problems of high catalyst cost, increased catalyst cost, unfavorable catalyst recovery, etc., achieve economical and environmental protection in the production process, and save post-processing costs , Excellent catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides a method for preparing a monoatomic iron-nitrogen-doped porous carbon catalyst, which includes the following steps:

[0065] Preparation of porous sheet-like hexagonal magnesium oxide template:

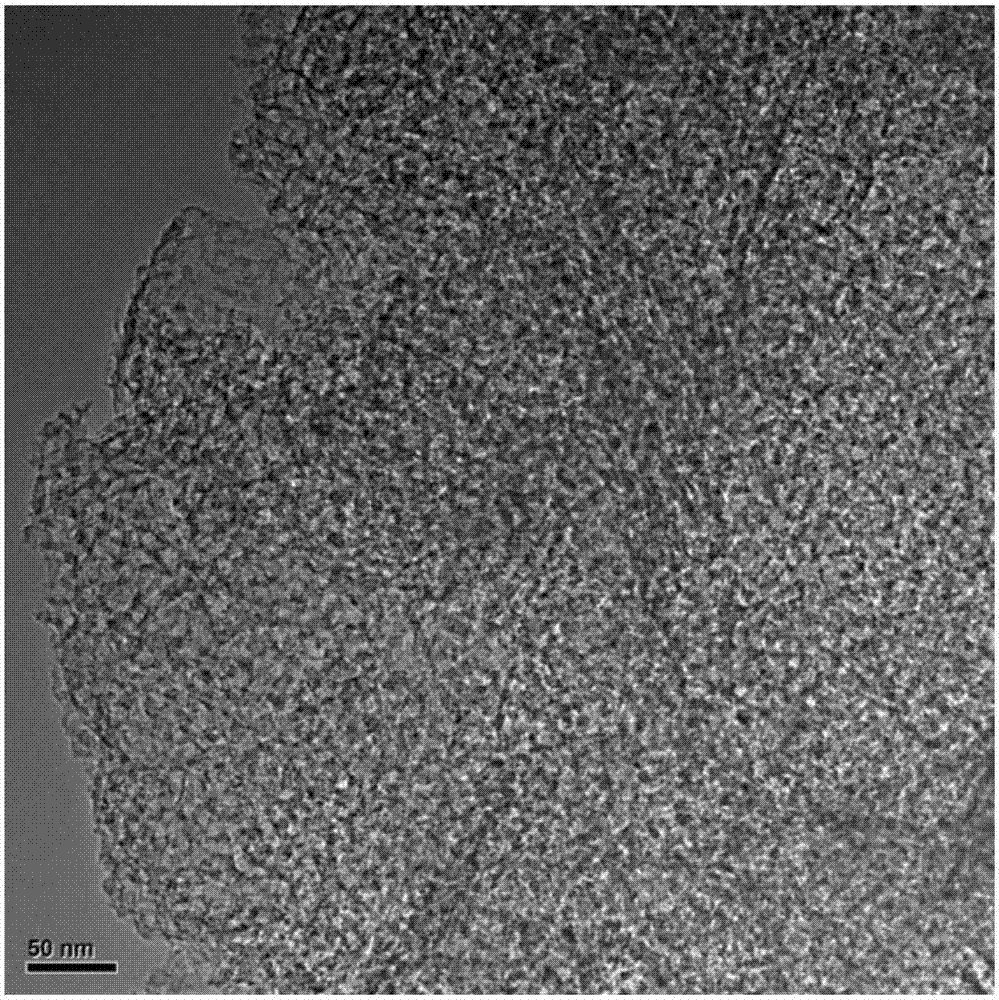

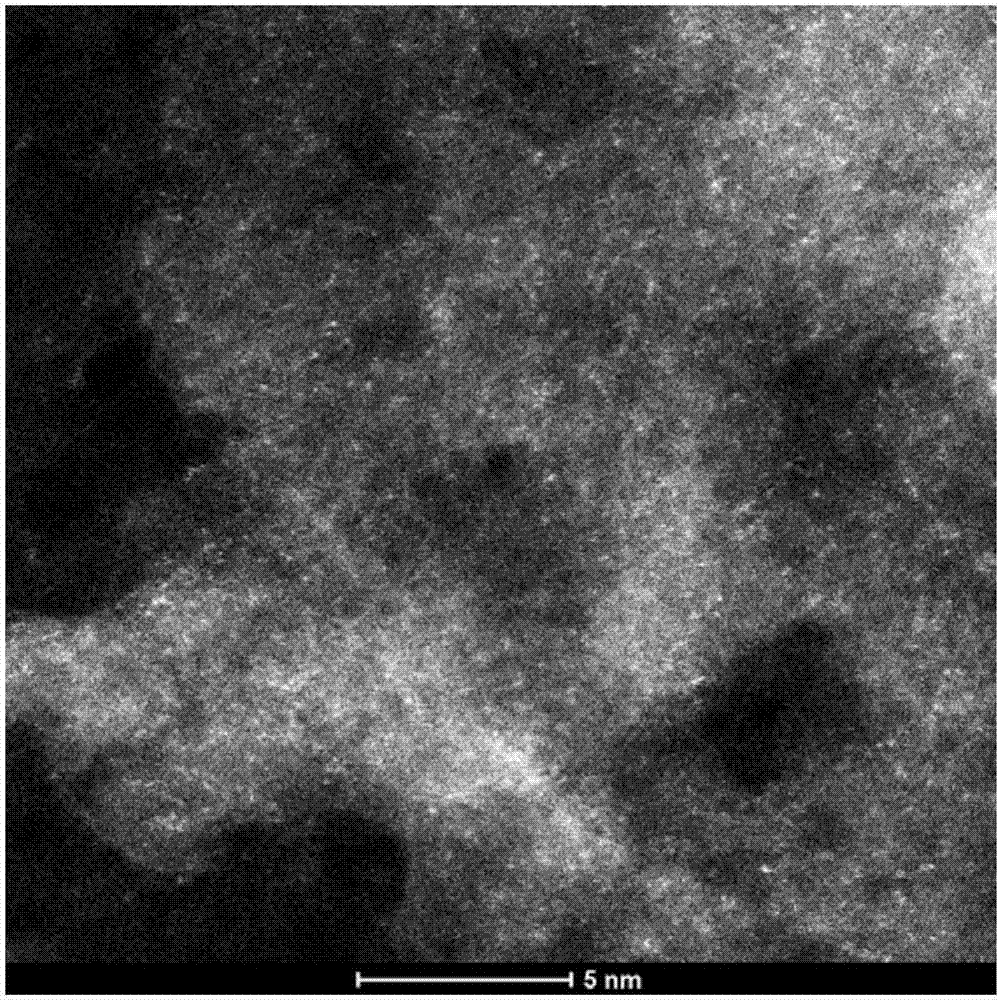

[0066] Disperse magnesium oxide powder in deionized water, reflux and boil for 24 hours, dry overnight at 80°C, cool the dried product to room temperature, then heat up to 450°C at a rate of 10°C per minute and bake for 60 minutes to obtain a porous sheet-shaped hexagonal Shaped magnesium oxide template, its specific surface area is 200m 2 / g, the two-dimensional film size is about 300nm;

[0067] Preparation of monoatomic iron nitrogen doped porous carbon catalyst:

[0068] Stir and dissolve 300mg ferric chloride and 500mg 2,2'-bipyridine in ethanol at room temperature, then add 1g of the magnesium oxide template prepared above, stir for 12h, remove the solvent, and dry to obtain a precursor mixture (solid mixture) ;

[0069] The precursor mixture ...

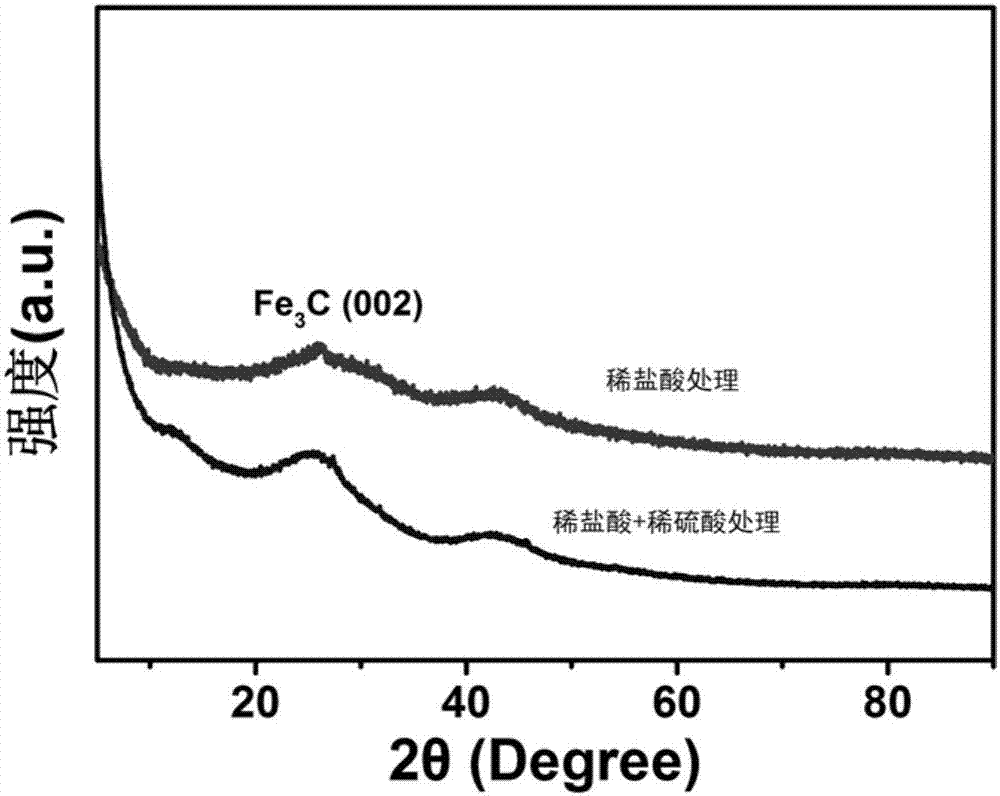

Embodiment 2

[0072] This embodiment provides a method for preparing a monoatomic iron-nitrogen-doped porous carbon catalyst, which includes the following steps:

[0073] Preparation of porous sheet-like hexagonal magnesium oxide template:

[0074] Disperse magnesium oxide powder in deionized water, reflux and boil for 24 hours, dry overnight at 80°C, and then heat up to 450°C at a heating rate of 10°C per minute and bake for 60 minutes to obtain a porous sheet-shaped hexagonal magnesium oxide template. The specific surface area 200m 2 / g, the two-dimensional film size is about 300nm;

[0075] Preparation of monoatomic iron nitrogen doped porous carbon catalyst:

[0076] Stirring and dissolving 300 mg of ferric chloride and 500 mg of 2,2'-bipyridine in ethanol at room temperature, then adding 1 g of the magnesium oxide template prepared above, stirring for 12 h, removing the solvent, and drying to obtain a precursor mixture;

[0077] The precursor mixture was placed in a tube furnace and...

Embodiment 3

[0088] This embodiment provides a method for preparing a monoatomic iron-nitrogen-doped porous carbon catalyst, which includes the following steps:

[0089] Preparation of porous sheet-like hexagonal magnesium oxide template:

[0090] Disperse magnesium oxide powder in deionized water, reflux and boil for 24 hours, dry overnight at 80°C, and then heat up to 450°C at a heating rate of 10°C per minute and bake for 60 minutes to obtain a porous sheet-shaped hexagonal magnesium oxide template. The specific surface area 200m 2 / g, the two-dimensional film size is about 300nm;

[0091] Preparation of monoatomic iron nitrogen doped porous carbon catalyst:

[0092] Stirring and dissolving 300 mg of ferric chloride and 500 mg of 2,2'-bipyridine in ethanol at room temperature, then adding 1 g of the magnesium oxide template prepared above, stirring for 12 h, removing the solvent, and drying to obtain a precursor mixture;

[0093] The precursor mixture was placed in a tube furnace and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com