Multiphase flow rotation foam separation device and waste water/ gas treatment technology using same

A technology of foam separation and multiphase flow, which is applied in combined devices, separation methods, water/sewage treatment, etc., can solve the problems of high construction and operation costs, large floor space, and low efficiency, and achieve small floor space and high installed capacity. The effect of small capacity and low project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] China Salt Group Co., Ltd. Xiangyu Project

[0029] Hydrazine hydrate wastewater project, daily treatment capacity: 500t / d,

[0030] Imported ammonia nitrogen: 6320mg / L, imported CODcr: 34600mg / L

[0031] Export ammonia nitrogen: 168mg / L, export CODcr: 1600mg / L

[0032] The final effluent flow direction: sent to the main sewage treatment station of the general plant, and after the final treatment is completed, it will be discharged up to the standard.

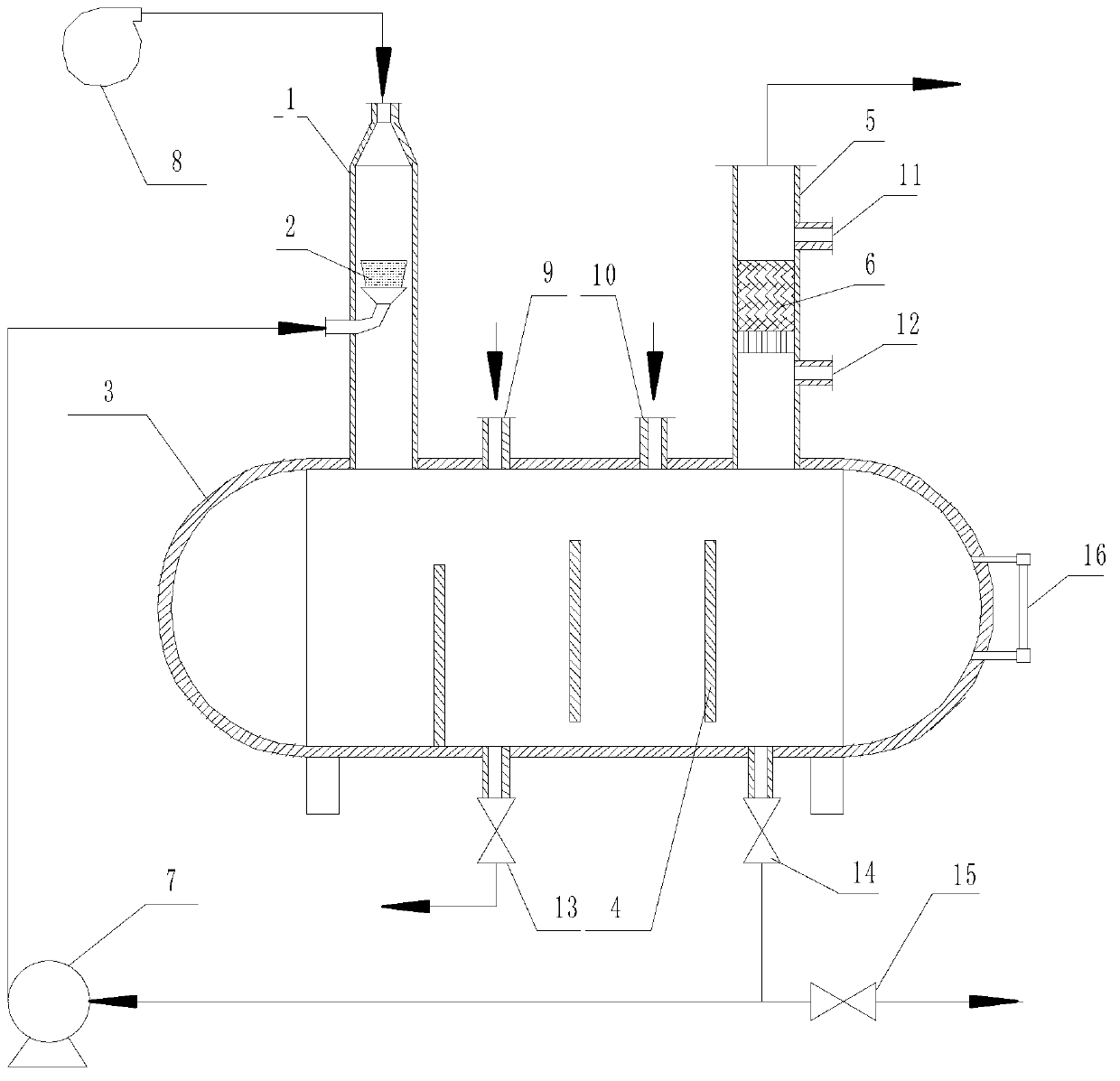

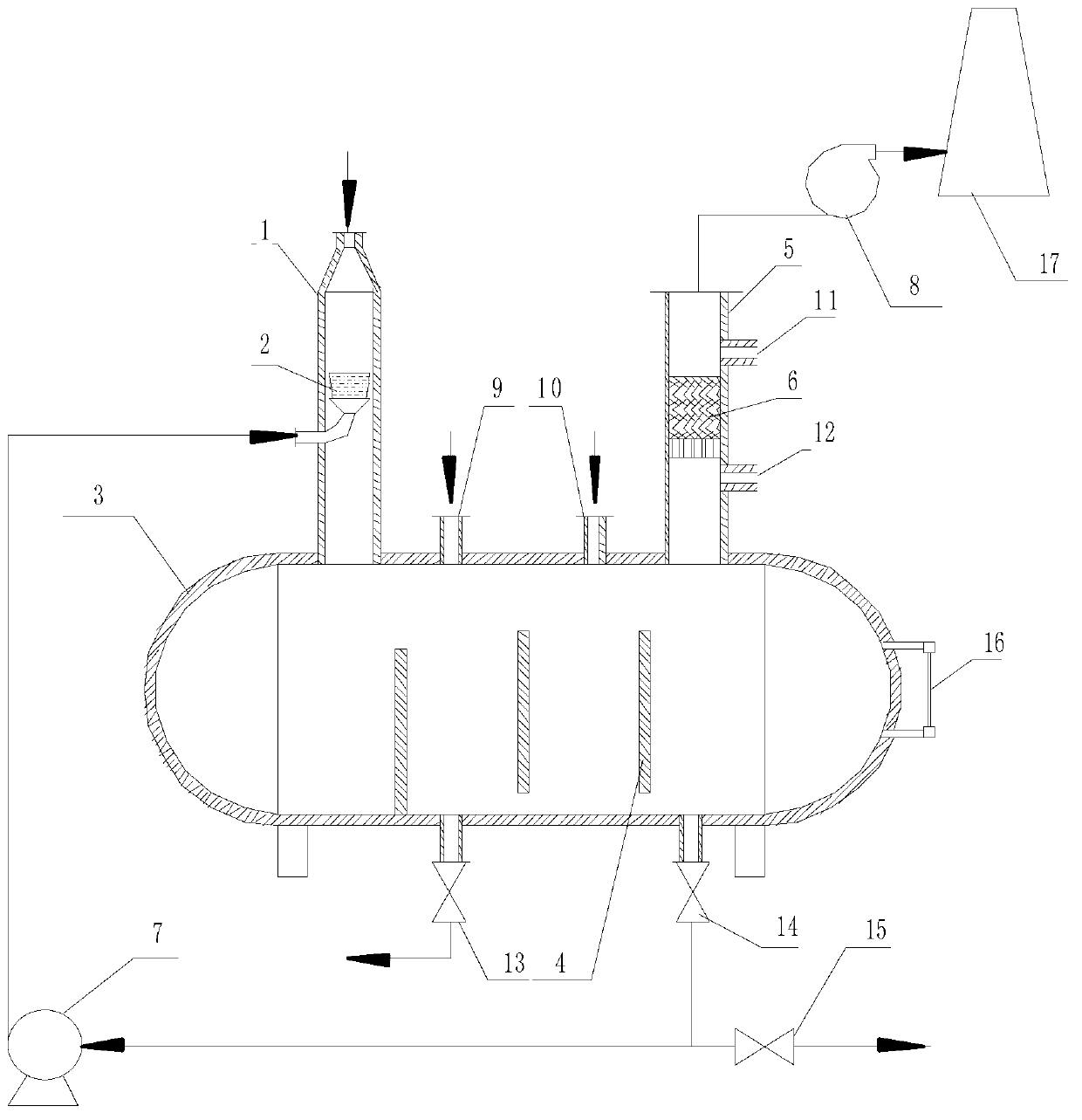

[0033] 1), first start the fan 8 to introduce air into the wave tube 1 of the multiphase flow rotating foam separation device, and close the liquid phase outlet valve 15 of the circulation tank 3 at the same time;

[0034] 2) Sewage is sent to the circulation tank 3 of the multiphase flow rotary foam separation device through the liquid phase inlet 9, and then the wastewater to be treated is sent to the rotary flow nozzle 2 of the wave tube 1 through the circulation pump 7, and the waste water introduced by the fan 8 ...

Embodiment 2

[0039] Hengyang Hailian salt brine chemical project

[0040] Soda making waste liquid full cycle project, daily processing capacity: 900t / d, deamination temperature 74°C

[0041] Composition of imported waste liquid:

[0042] NaHCO 3 : 10.12gL, NaCl: 64.26g / L, NaCl 2 SO 4 : 20.84g / L,

[0043] NH 4 HCO 3 : 74.66gL, NH 4 Cl: 187.48g / L;

[0044] The composition of the export waste liquid:

[0045] NaHCO 3 : 9.28gL, NaCl: 64.15gL, NaCl 2 SO 4 : 20.72gL,

[0046] NH 4 HCO 3 : 11.92gL, NH 4 Cl: 184.38gL;

[0047] The waste liquid is sent to the heat exchanger through the sewage to raise the temperature to the expected temperature to decompose the C in the liquid 2 O and free ammonia are then sent to the first-stage parallel multiphase flow rotary foam separation device to blow off the NH 4 HCO 3 The content of NH content is reduced to less than 30%. After passing the standard, the feed liquid is pumped to the second-stage multiphase flow rotary foam separation dev...

Embodiment 3

[0049] Changsha Shengxi Manganese Industry Project

[0050] Daily treatment capacity of electrolytic manganese wastewater: 120t / d, process design: three-stage single-pipe stripping + sepiolite adsorption

[0051] Imported ammonia nitrogen: 3260mg / L, ammonia titer at the outlet of ammonia absorption tower: 29.2tt

[0052] Ammonia nitrogen export: first grade 689mg / L, second grade: 366mg / L, third grade: 105mg / L;

[0053] Sepiolite adsorption tower outlet: 12.8mg / L.

[0054] The sewage discharged to the sewage pool is sent to the first-stage parallel multiphase flow rotary foam separation device by circulating pumps for alternate and intermittent blowoff, and the pH value is controlled at about 11 at the same time. After the free ammonia is blown off to below 800mg / L, the feed liquid is pumped to the second-stage parallel multiphase flow rotary foam separation device to blow off the ammonia nitrogen to below 150mg / L, and then the feed liquid is pumped to the sepiolite adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com