Method for extracting and separating panax japonicus saponin and polysaccharide

A technology of ginseng saponins and ginseng polysaccharides, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of poor adsorption selectivity, high technical difficulty and large investment of macroporous adsorption resin technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Extraction and separation method of bamboo ginseng saponin and polysaccharide of the present invention

[0082] The method steps are as follows:

[0083] A. Extraction of Bamboo Ginseng:

[0084] Weigh 40 parts by weight of 25 mesh bamboo ginseng powder, add water according to the weight ratio of bamboo ginseng powder and water to 15, extract 3 times under micro-boiling conditions, each 2h, filter, and these filtrates are combined to obtain the described bamboo ginseng powder. Radix Ginseng Extract;

[0085] B. pH adjustment

[0086] Use 1mol L -1 Hydrochloric acid aqueous solution and 1mol L -1 Sodium hydroxide aqueous solution adjusts the pH of the bamboo ginseng extract obtained in step (A) to 4.8;

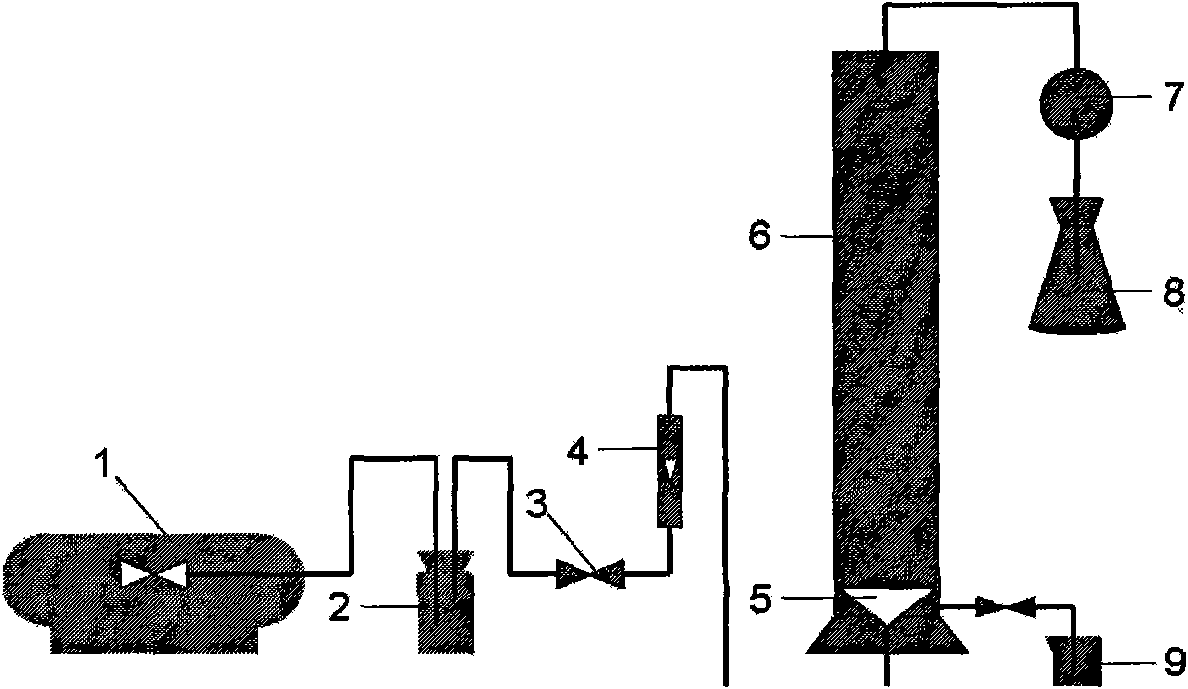

[0087] C. Foam separation:

[0088] Use the foam separation device of the present invention to carry out, the bamboo ginseng extract that step (B) obtains is added in the foam separation tower 6, by the air or nitrogen gas of the high-pressure cylinder 1 by the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com