Coke oven gas desulfurization equipment

A coke oven gas and desulfurization equipment technology, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve the problems of desulfurization efficiency reduction, achieve the effects of preventing ammonia loss, increasing spraying density, and increasing spraying volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

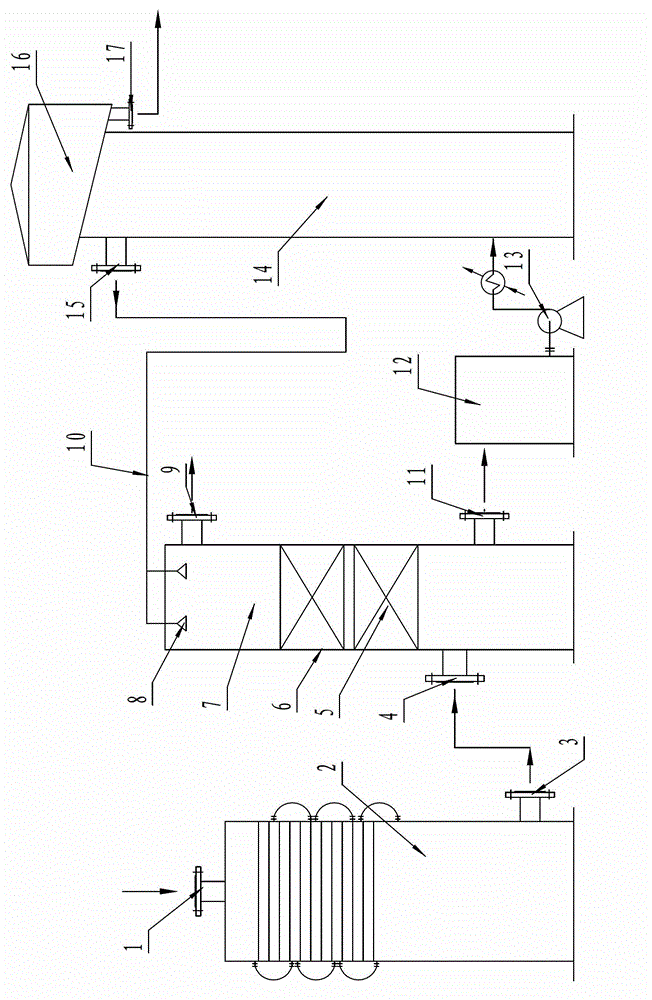

[0027]Embodiment 1, a kind of coke oven gas desulfurization equipment, its structure is: mainly comprises the gas indirect cooler connected together by pipeline, desulfurization tower, regeneration tower composition,

[0028] The connection relationship between each equipment is as follows: the gas outlet 3 of the gas indirect cooler 2 is connected to the gas inlet 4 of the desulfurization tower at the bottom of the desulfurization tower, the desulfurization liquid nozzle 8 is installed on the top of the desulfurization tower 6, and the purified gas outlet 9 is installed on the upper part of the desulfurization tower. The desulfurization waste liquid outlet 11 at the bottom is connected to the regeneration tower 14 through the solution circulation tank 12 and the pump 13. The upper part of the regeneration tower is provided with a regenerated desulfurization liquid outlet 15 and connected to the desulfurization tower through a desulfurization liquid circulation pipeline 10. The...

Embodiment 2

[0029] Embodiment 2, a kind of coke oven gas desulfurization equipment, its structure is: mainly comprises the gas indirect cooler connected together by pipeline, desulfurization tower, regeneration tower composition,

[0030] The connection relationship between each equipment is as follows: the gas outlet 3 of the gas indirect cooler 2 is connected to the gas inlet 4 of the desulfurization tower at the bottom of the desulfurization tower, the desulfurization liquid nozzle 8 is installed on the top of the desulfurization tower 6, and the purified gas outlet 9 is installed on the upper part of the desulfurization tower. The desulfurization waste liquid outlet 11 at the bottom is connected to the regeneration tower 14 through the solution circulation tank 12 and the pump 13. The upper part of the regeneration tower is provided with a regenerated desulfurization liquid outlet 15 and connected to the desulfurization tower through a desulfurization liquid circulation pipeline 10. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com