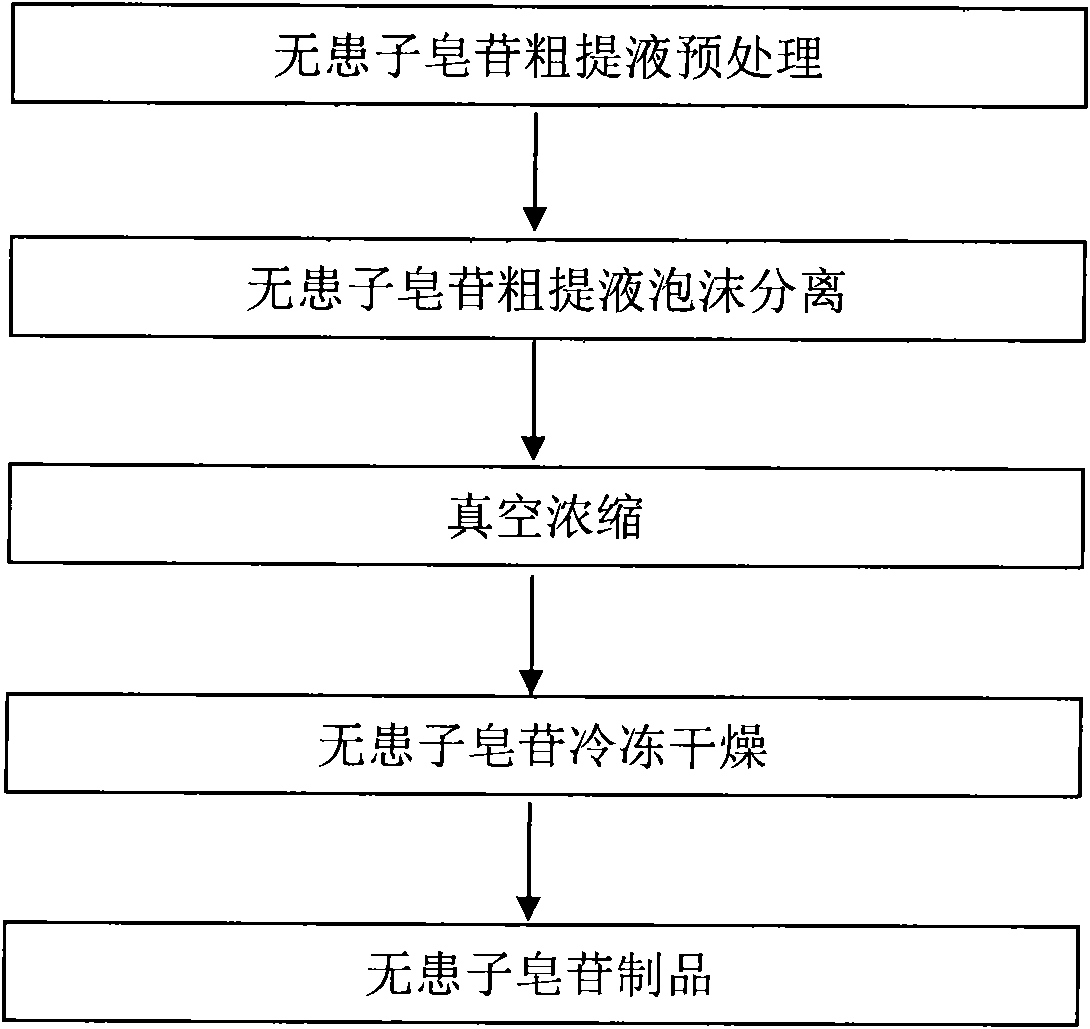

Method of separating soapnut saponin with foam separation method

A technology for the separation of sapindus saponin and foam, which is applied in the field of sapindus saponin foam separation method, and can solve the problems of high cost and low yield of sapindus saponin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Preparation of Sapindus saponin crude extract

[0027] Crush 1000kg of dried Sapindus chinensis fruit, pass through a 40-mesh sieve, extract with 75% ethanol for 2 hours (solid-liquid ratio 1:6), and separate by solid-liquid filtration; follow this process for reflux extraction twice. Combine the extracts, recover ethanol under reduced pressure to a volume of 2L, add water to dilute to 6L, adjust the pH value to 4 with hydrochloric acid, filter to remove precipitates, and obtain Sapindus saponin crude extract.

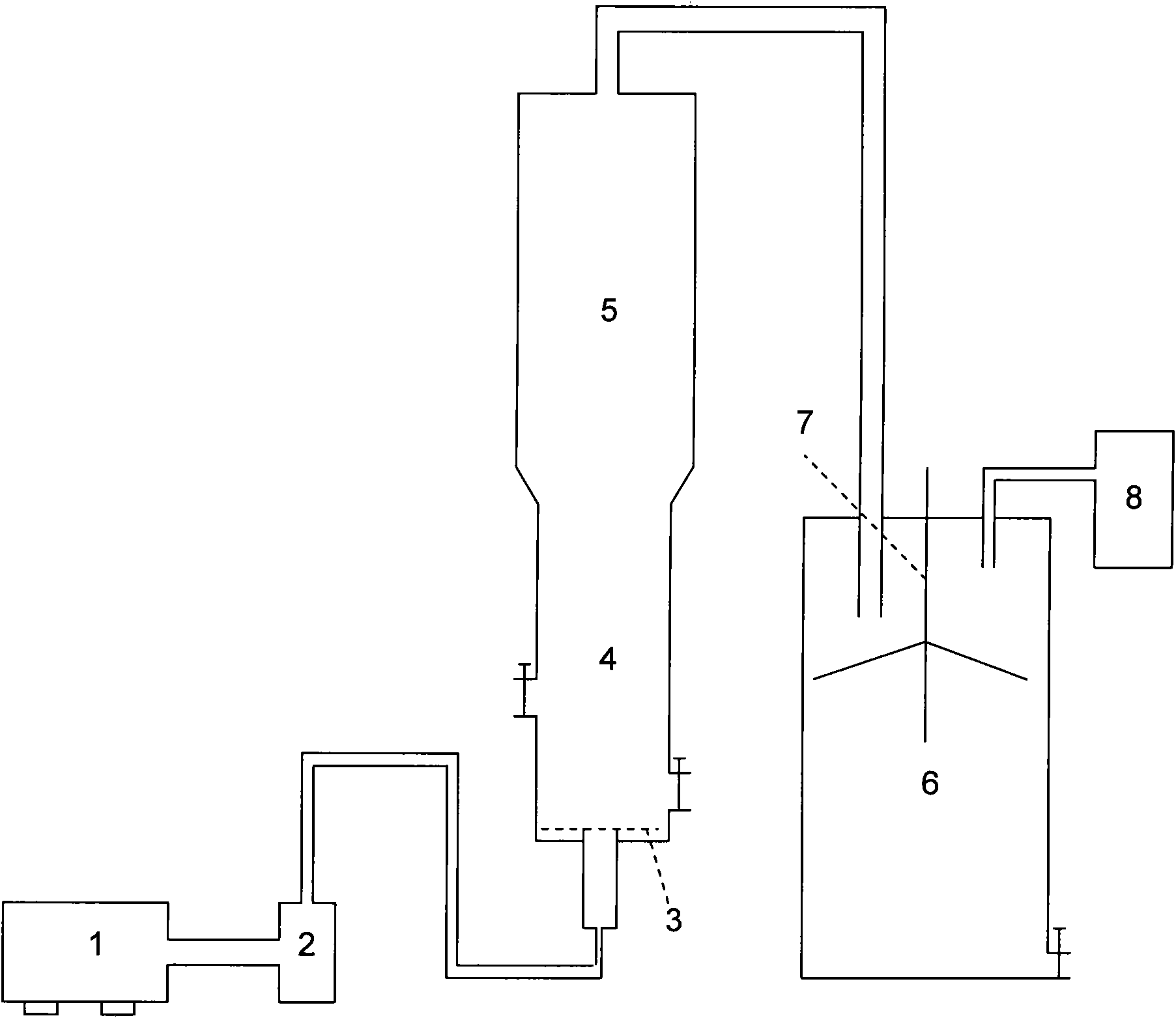

[0028] b. Foam separation

[0029] The crude saponin extract was foam-separated with a bubble column at a temperature of 35°C, a pH of 4, and a bubbling air velocity of 1×10 -3 m / s, the foam-breaking method adopts the organic solvent method, adds absolute ethanol to the spray flow of 2.5% of the foam liquid amount, and the operation time of one cycle is 3 hours to obtain a high-concentration Sapindus sapindus saponin foam-breaking liquid, and its concentrati...

Embodiment 2

[0035] a. Preparation of Sapindus saponin crude extract

[0036] Crush 2000kg of dried Sapindus chinensis fruit, pass through a 40-mesh sieve, extract with 50% ethanol for 2 hours (solid-liquid ratio 1:6), and separate by solid-liquid filtration; reflux extraction twice according to this process. Combine the extracts, recover ethanol under reduced pressure to a volume of 5 L, add water to dilute to 10 L, adjust the pH value to 4 with hydrochloric acid, and filter to remove precipitates to obtain a crude extract of Sapindus saponins.

[0037] b. Foam separation

[0038] The crude saponin extract was foam-separated with a bubble column at a temperature of 35°C, a pH of 4, and a bubbling air velocity of 1×10 -4 m / s, the foam breaking method adopts the mechanical shear stirring method, and the operating time of one cycle is 4 hours to obtain a high-concentration Sapindus sapindus saponin breaking foam solution, and its concentration ratio is 18 times.

[0039] c. Vacuum evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com