Heat pipe for electronic wine cabinet and cold and heat generation device

A generating device and heat pipe technology, applied to machines using electric/magnetic effects, refrigerators, heat exchange equipment, etc., can solve problems such as heat pipe corrosion, shortened service life of heat pipes, pollution, etc., to prolong service life and reduce impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

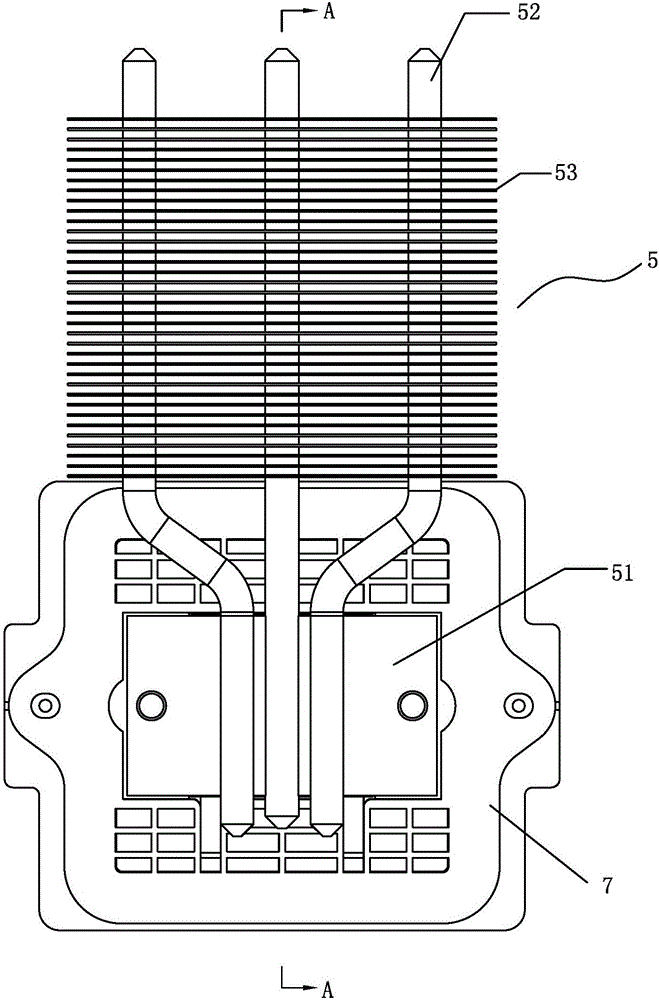

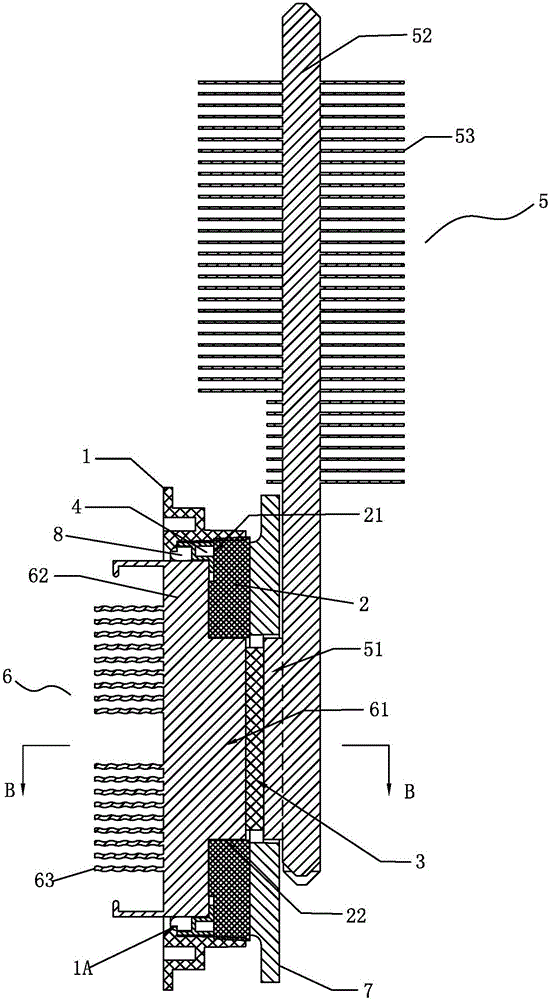

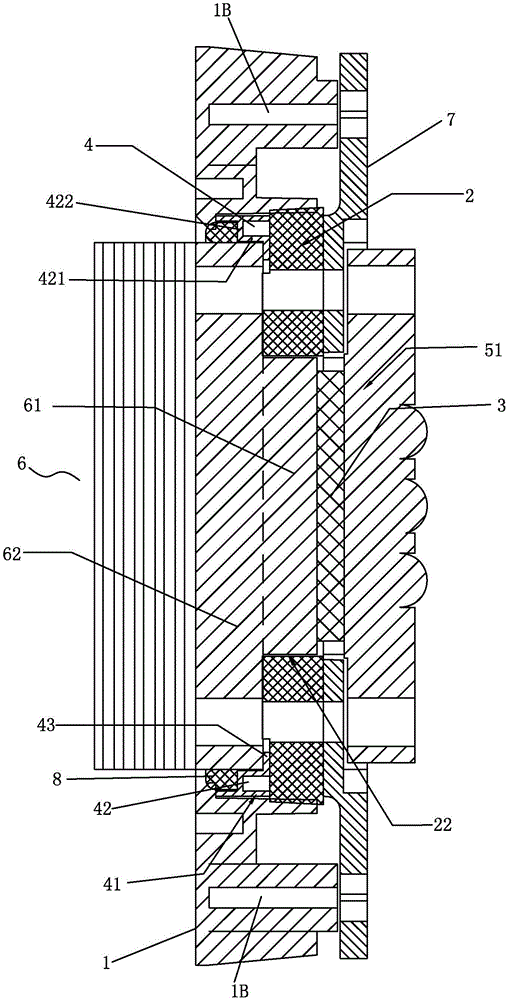

[0022] Such as figure 1 As shown, a cold and heat generating device for an electronic wine cabinet includes a shell 1 with front and rear openings, a foam partition 2, a semiconductor cooling plate 3, a heat insulating frame 4, a heat pipe 5, a heat dissipation aluminum 6 and a cover with a central hole The plate 7, the heat dissipation aluminum 6 includes a cooling block 61, a base body 62 and several cooling fins 63 arranged on the base body; Refrigerant; there is an inner gusset 1A in the front opening end of the shell 1; the foam partition 2 is located in the shell 1, the front end of the foam partition 2 has a step 21, and the center of the foam partition 2 has a cold guide block hole 22; The heat frame 4 is arranged on the step 21, the base body 62 is arranged on the heat insulation frame 4, the cold guide block 61 extends into the hole 22 of the cold guide bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com