Circulating lubricating system with automatic cleaning function

A cyclic lubrication and automatic cleaning technology, applied in sedimentation tanks, chemical instruments and methods, separation methods, etc., can solve the problems of difficult to clean impurities, turbid lubricating liquid, and reducing the lubricating performance of lubricating liquid, so as to reduce the generation of foam, reduce The generation of waste water, the effect of improving lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

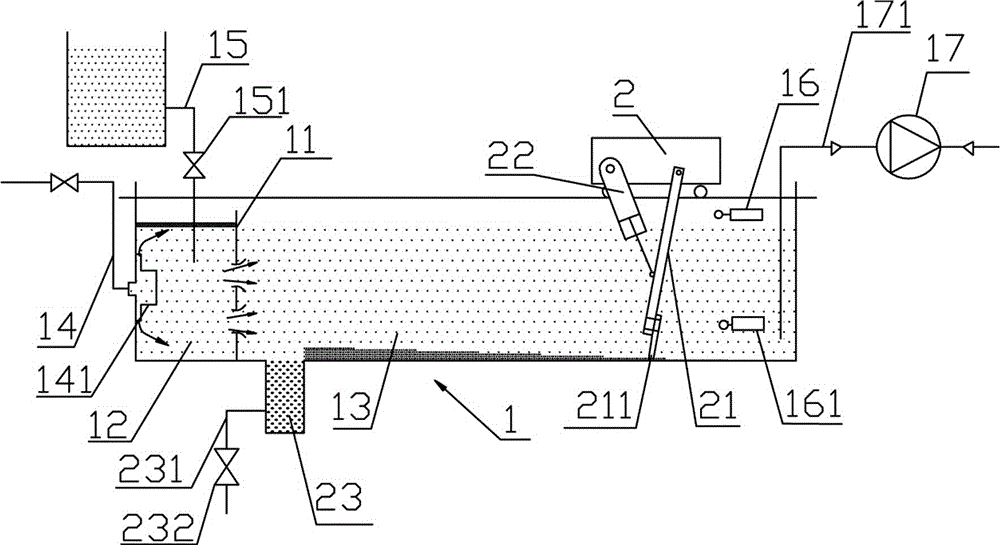

[0018] A circulating lubrication system with automatic cleaning function, such as figure 1 As shown, including a sedimentation tank 1, a foam partition 11 capable of blocking the surface foam of the lubricating liquid is arranged in the sedimentation tank 1, and the foam partition 11 separates the sedimentation tank 1 into a foam isolation zone 12 and an impurity precipitation zone 13, and the impurity precipitation zone The length of 13 is 20~30m. A liquid return pipe 14 is arranged in the foam isolation area 12. The lubricating liquid containing impurities enters the foam isolation area 12 through the liquid return pipe 14, and then enters the impurity precipitation area 13 to precipitate impurities. This setting can The foam is isolated in the foam isolation zone 12, so as not to affect the precipitation of impurities in the impurity p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com