Construction method for cast-in-situ foam separation wall for tailing filling mining

A filling mining and construction method technology, which is applied in the direction of filling, mining equipment, earth square drilling, etc., can solve the problems of non-recycling, difficult quicksand isolation, difficult recycling and reuse, etc., and achieve good shock resistance and impact resistance. Good economic benefits and the effect of making up for construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

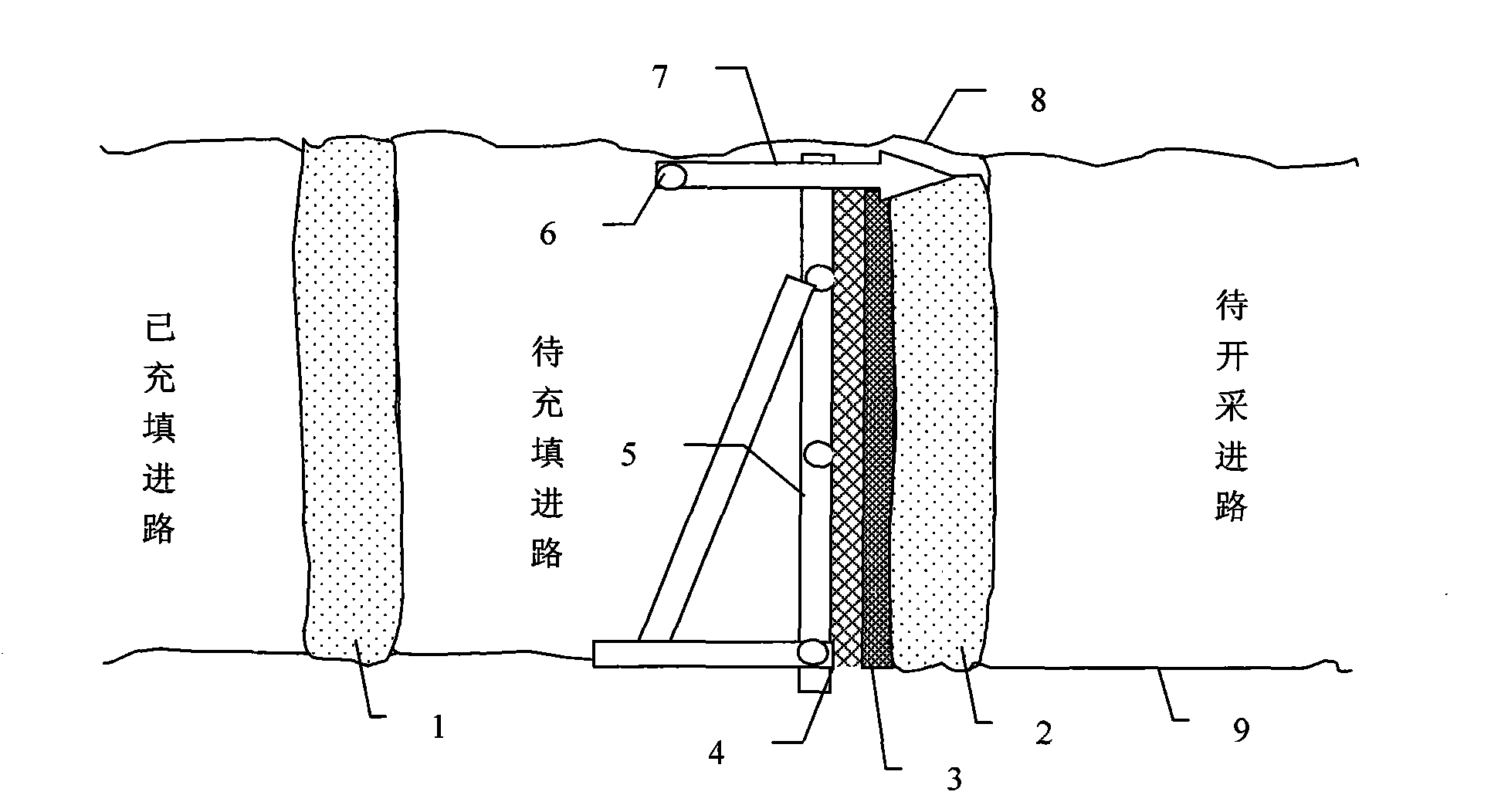

[0031] Embodiment 1 is used for the construction method of cast-in-place foam separation wall for tailings filling mining, and the steps are as follows:

[0032]Step 1: Clean the bottom plate and build scaffolding 5 on the side of the gob approach near the concrete wall of the road to be mined, within 0.4-0.8m, preferably 0.5-0.6m, of the concrete wall along the approach. The spacing between the vertical steel pipes of the scaffold is 0.8-1.5m, preferably 0.8-1.0m. Before setting up, use a rock drill to drill a hole of 0.3-0.5m on the floor, and then insert the vertical steel pipes into it; the spacing of the horizontal steel pipes is 0.5m. -1.5m, preferably 0.7-0.8m, among them, two horizontal steel pipes should be used at the bottom, and the distance from the bottom plate should not exceed 10cm.

[0033] Step 2: Use a hook, or thin iron wire, or use a thin rope to fix Chenglishan 4 to the scaffold 5, and then hang and paste the isolation cloth 3 on Chenglishan 4, and place i...

Embodiment 2

[0037] Example 2 In a gold mine, an upward horizontal approach is adopted for layered mining, and the section size of a single approach is 4m wide and 3m high. The extension length of a single entry is generally 300m-400m, and the daily depth is about 30m. In the past, high-water cement glue ending sand-type cemented filling with a lime-sand ratio = 1:20, and a 1:10 lime-sand roofing process were used, and the overall cost was 40 yuan / m 3 The comprehensive cost per m depth is about 480 yuan.

[0038] Now use the foam separation wall-water sand filling method (construction method of cast-in-place foam separation wall for tailings filling mining), the specific implementation process is:

[0039] Step 1: Clean the bottom plate and build scaffolding on the side of the goaf approach that is close to the concrete wall of the road to be mined, and within an average range of 0.6m from the concrete wall along the approach. Among them, the distance between the vertical steel pipes of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com