Method for separating whey protein from whey wastewater by foam separation method

A foam separation method and whey wastewater technology, applied in the field of waste water resource recycling, can solve the problems of low protein foam separation efficiency, limited whey protein reuse, unprocessed technology, etc., to achieve simple equipment, avoid waste, and avoid environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

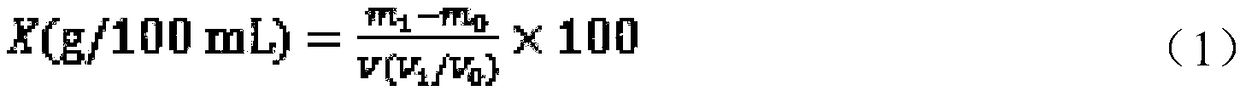

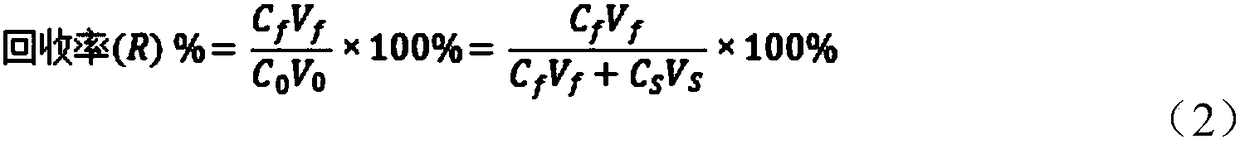

[0071] Effects of whey protein concentration on the separation of yak whey protein foam

[0072] The yak whey wastewater was adjusted to pH 4.0-5.0 with 0.5mol / L NaOH solution and 0.5mol / L HCl solution, centrifuged at 10,000rpm for 10min at 4°C, repeated 3 times to remove fat, and the whey wastewater after treatment The medium fat content is less than 0.414g / L, and the whey protein content is 5.242g / L.

[0073] The mass concentration of whey protein in the defatted yak whey wastewater was diluted with deionized water to 70, 100, 130, 160, 190, 230, 260 μg / mL, and the diluted yak whey wastewater solution was diluted with 0.5mol / L The pH value of NaOH solution and 0.5mol / L HCl solution is adjusted to 4.3, and the diluted and pH adjusted yak whey wastewater solution is placed in a constant temperature water bath to keep the temperature constant until the temperature of the whey wastewater solution is 45°C.

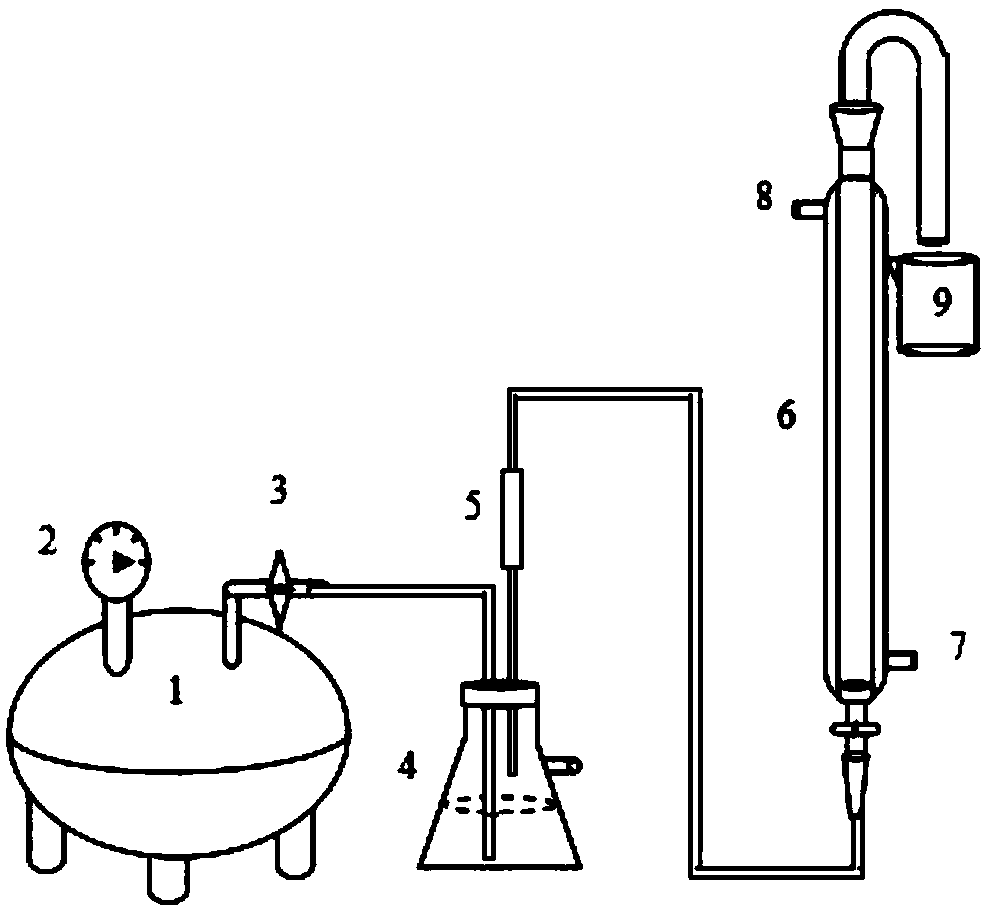

[0074] The treated skim whey wastewater solution was injected into a ci...

Embodiment 2

[0080] The effect of temperature on the separation of yak whey protein foam

[0081] The method of Example 1 was used to separate the whey protein in the yak whey wastewater. The whey protein concentration was set to 130 μg / mL, and the temperature of the yak whey wastewater diluent and the foam separation column were adjusted to 20, 25, 30, 35, 40, 45, 50, and 55 °C, respectively, and other parameters and methods were implemented in the same way. example 1.

[0082] Table 2 Whey protein recovery and enrichment ratio at different temperatures

[0083] temperature ℃

[0084] Temperature significantly affects the surface tension of the solution, the stability of the foam and the rate of liquid reflux in the foam layer, thereby affecting the foam separation effect. As shown in Table 2, at 20-55 °C, with the increase of temperature, the recovery first increased and then decreased, and the enrichment ratio first decreased and then increased. At 35 °C, the recovery rate r...

Embodiment 3

[0086] Effect of pH value on separation effect of yak whey protein foam

[0087] The method of Example 1 was used to separate the whey protein in the yak whey wastewater. The whey protein concentration was set to 130 μg / mL, and the pH values of the yak whey wastewater diluent were adjusted to 3.3, 3.8, 4.3, 4.8, 5.3, 5.8, and 6.3, respectively. Other parameters and methods were the same as those in Example 1.

[0088] Table 3 Whey protein recovery and enrichment ratio at different pH values

[0089]

[0090]

[0091] The pH value significantly affects the physicochemical properties of yak whey protein in aqueous solution, such as the net charge, solubility, interfacial tension and foam strength, etc., and has a significant impact on the foam separation performance of yak whey protein. As shown in Table 3, as the pH value increased from 3.3 to 6.3, the recovery first increased and then decreased, while the enrichment ratio gradually decreased. For the recovery rate, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com