Circulating sewage treatment method and device

A technology of sewage discharge and treatment cycle, applied in the direction of oxidized water/sewage treatment, etc., can solve problems such as unsatisfactory effect, and achieve the effect of reducing ozone consumption, improving treatment efficiency and short contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

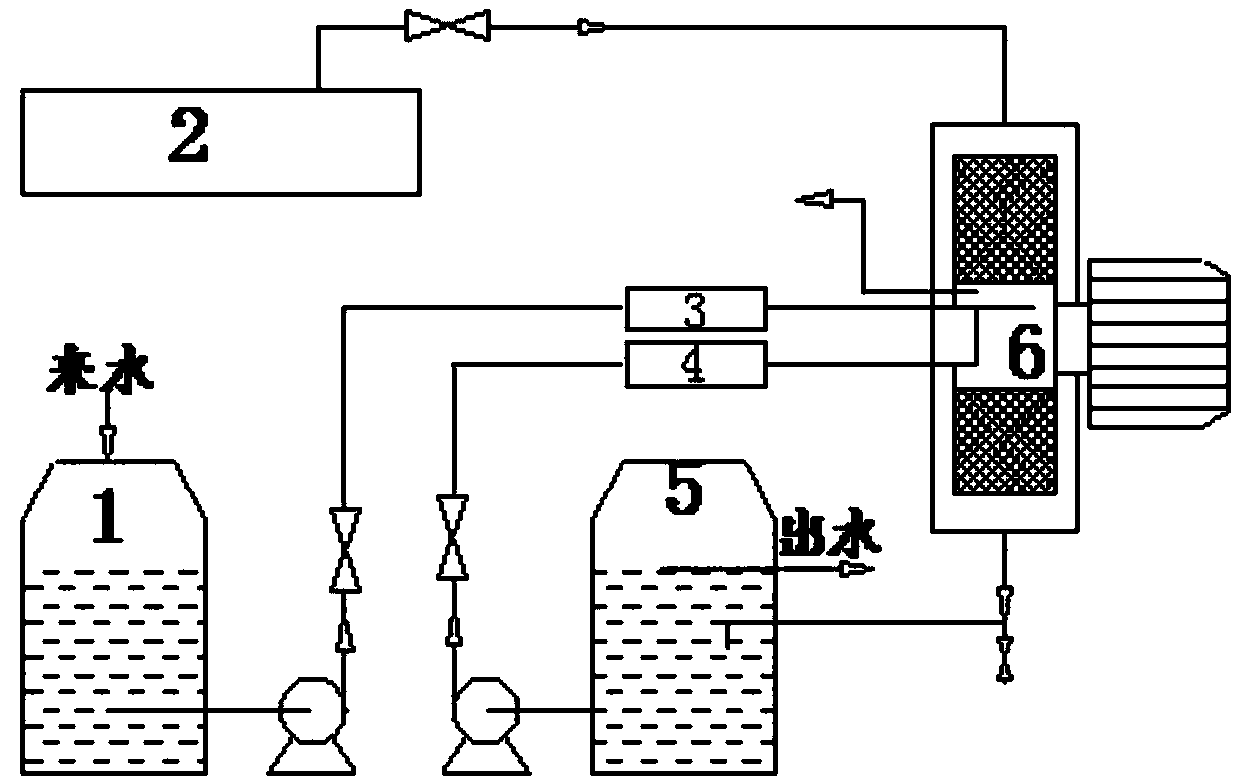

Image

Examples

Embodiment 1

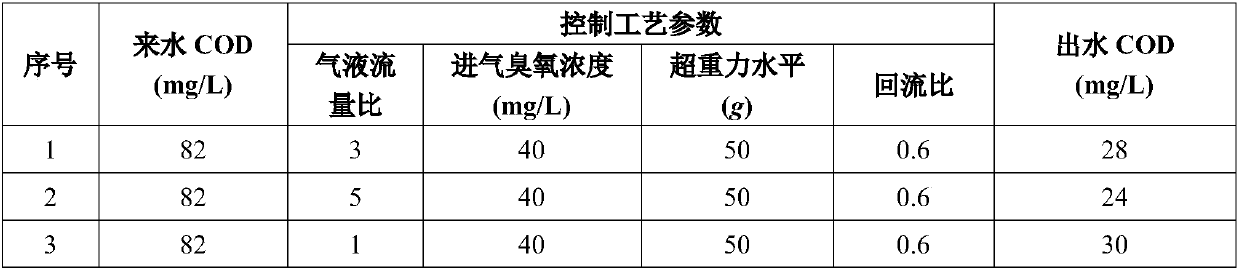

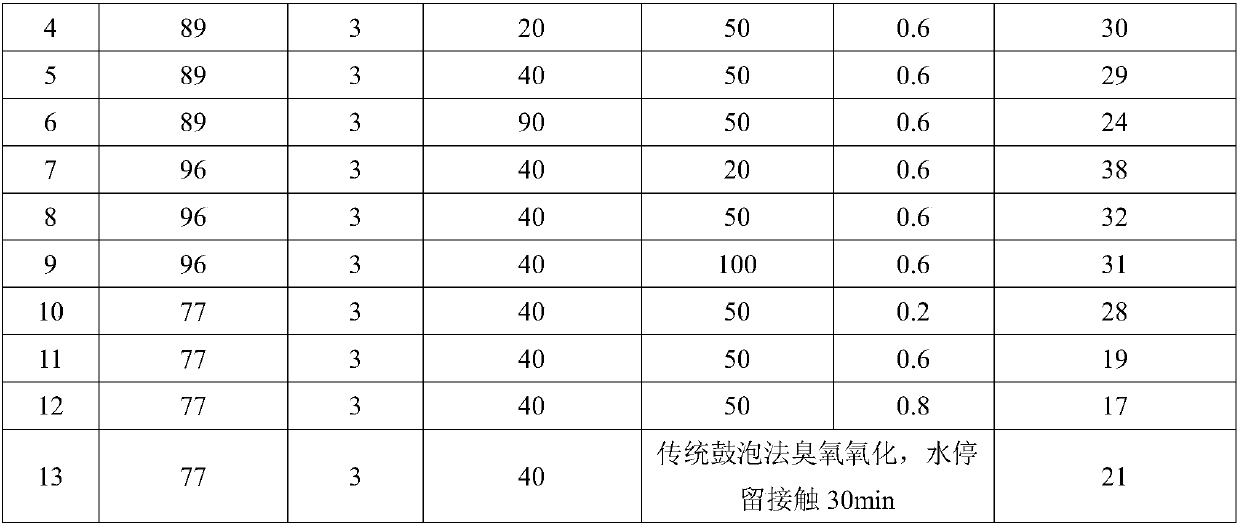

[0027]The circulating sewage after the front-end coagulation and sedimentation treatment reaches the incoming water pool 1, and the measured COD of the incoming water is 82mg / L. The water in the incoming water pool 1 is transported by the pump and measured by the inflow flow meter 3, and then reaches the supergravity reactor 6; the ozone-containing gas is generated by the ozone generation system 2, and is also transported to the supergravity reaction after being measured by the flow meter and the ozone concentration meter. Device 6, the ozone concentration is 40mg / L. The gas-liquid flow ratio in the control hypergravity reactor 6 is 3. The rotor in the supergravity reactor 6 rotates to form a supergravity environment, and the supergravity level G is controlled at 50g. In this case, the water comes into contact with the ozone quickly, the ozone reacts quickly with the pollutants (within 1 second of liquid residence time), and the pollutants are degraded. Then, the water phase...

Embodiment 2

[0029] The circulating sewage after the front-end coagulation and sedimentation treatment reaches the incoming water pool 1, and the measured COD of the incoming water is 82mg / L. The water in the incoming water pool 1 is transported by the pump and measured by the inflow flow meter 3, and then reaches the supergravity reactor 6; the ozone-containing gas is generated by the ozone generation system 2, and is also transported to the supergravity reaction after being measured by the flow meter and the ozone concentration meter. Device 6, the ozone concentration is 40mg / L. Control the gas-liquid flow ratio in the hypergravity reactor 6 to be 5. The rotor in the supergravity reactor 6 rotates to form a supergravity environment, and the supergravity level G is controlled at 50g. In this case, the water comes into contact with the ozone quickly, the ozone reacts quickly with the pollutants (within 1 second of liquid residence time), and the pollutants are degraded. Then, the water p...

Embodiment 3

[0031] The circulating sewage after the front-end coagulation and sedimentation treatment reaches the incoming water pool 1, and the measured COD of the incoming water is 82mg / L. The water in the incoming water pool 1 is transported by the pump and measured by the inflow flow meter 3, and then reaches the supergravity reactor 6; the ozone-containing gas is generated by the ozone generation system 2, and is also transported to the supergravity reaction after being measured by the flow meter and the ozone concentration meter. Device 6, the ozone concentration is 40mg / L. Control the gas-liquid flow ratio in the hypergravity reactor 6 to be 1. The rotor in the supergravity reactor 6 rotates to form a supergravity environment, and the supergravity level G is controlled at 50g. In this case, the water comes into contact with the ozone quickly, the ozone reacts quickly with the pollutants (within 1 second of liquid residence time), and the pollutants are degraded. Then, the water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com