Flue gas desulfurization and denitration integrated equipment controlled through multiple variables and control method thereof

A multi-variable control, desulfurization and denitrification technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of insufficient desulfurization and denitrification, increase costs, etc., reduce ozone consumption, reduce equipment operating costs, and optimize operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

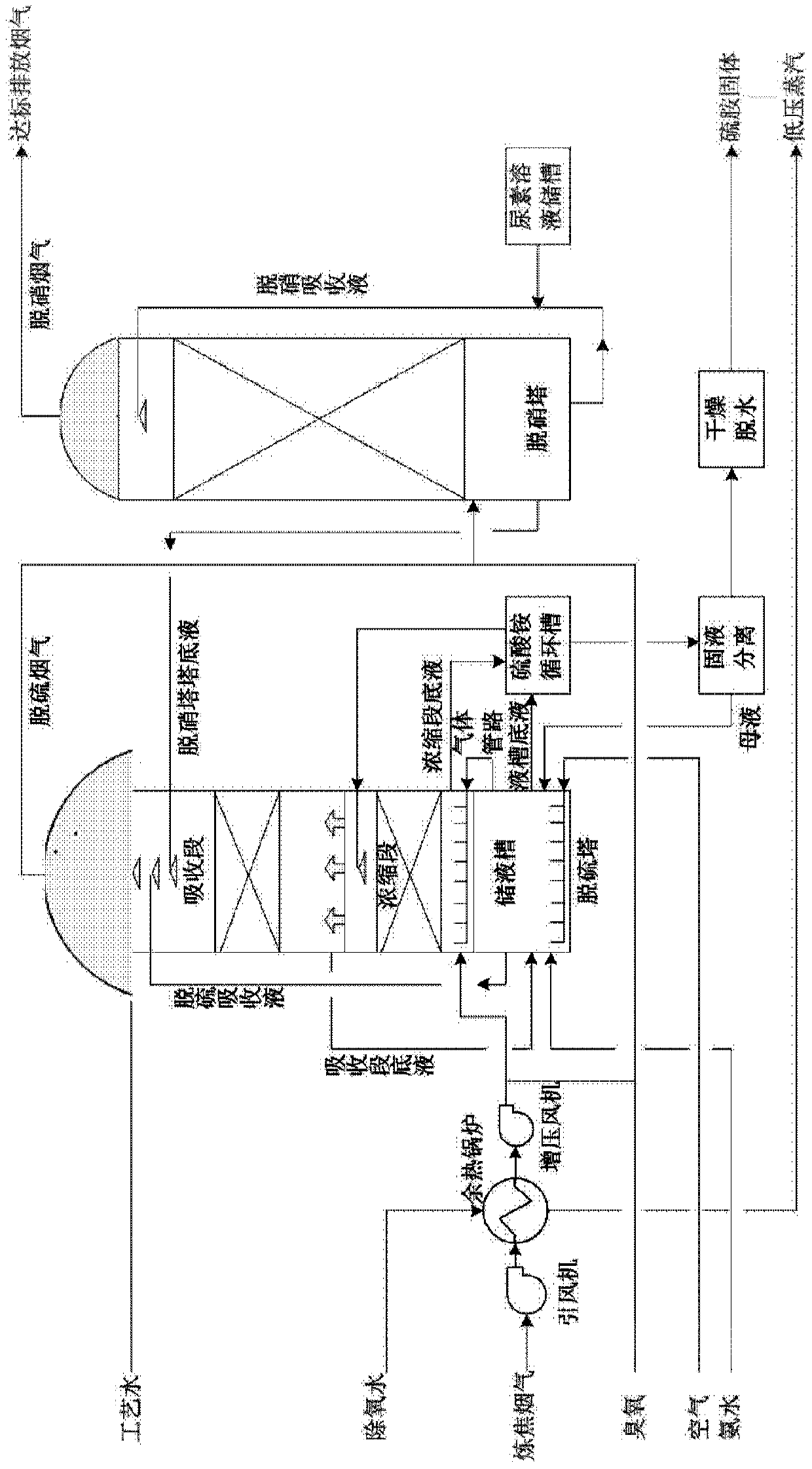

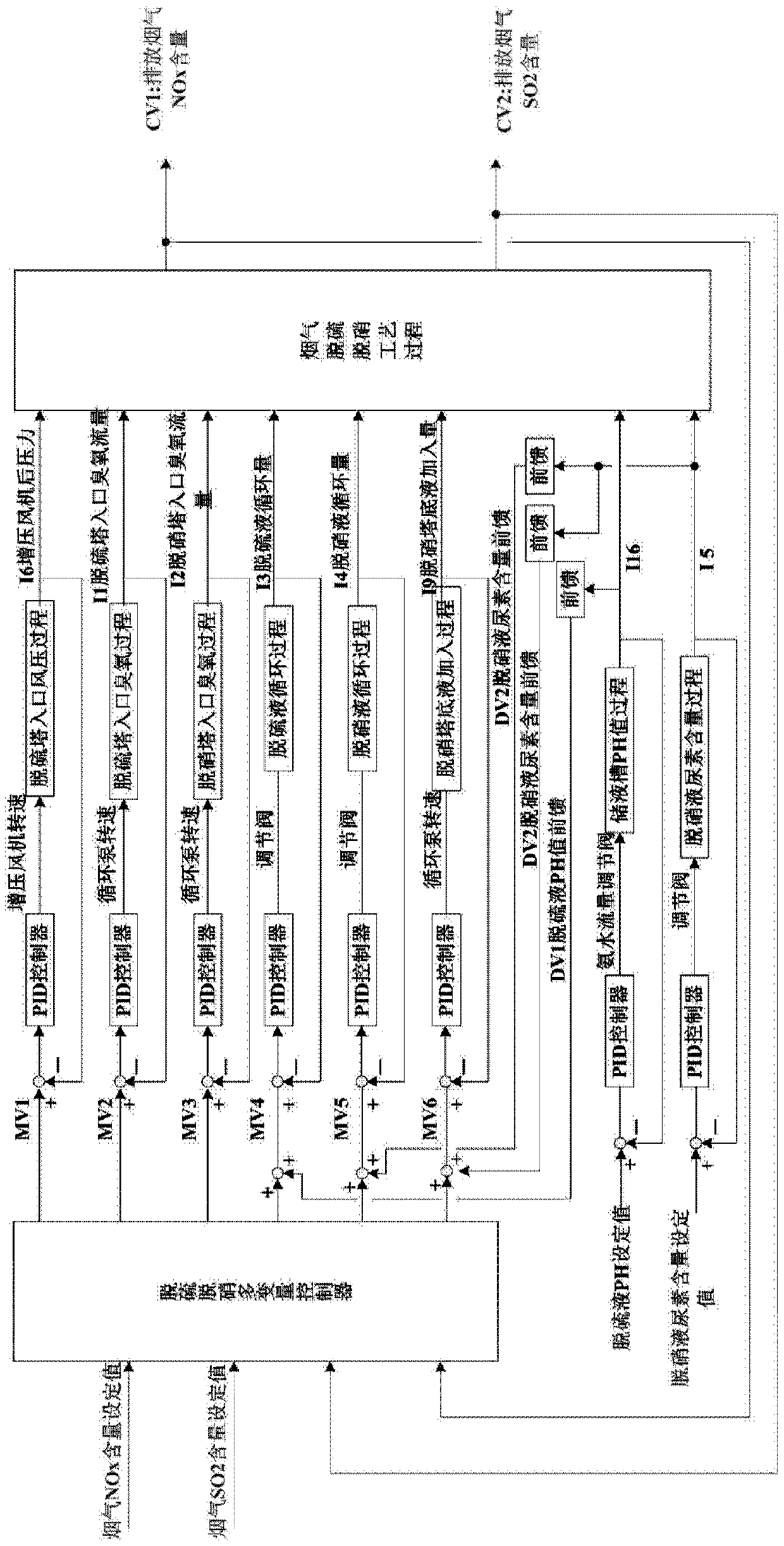

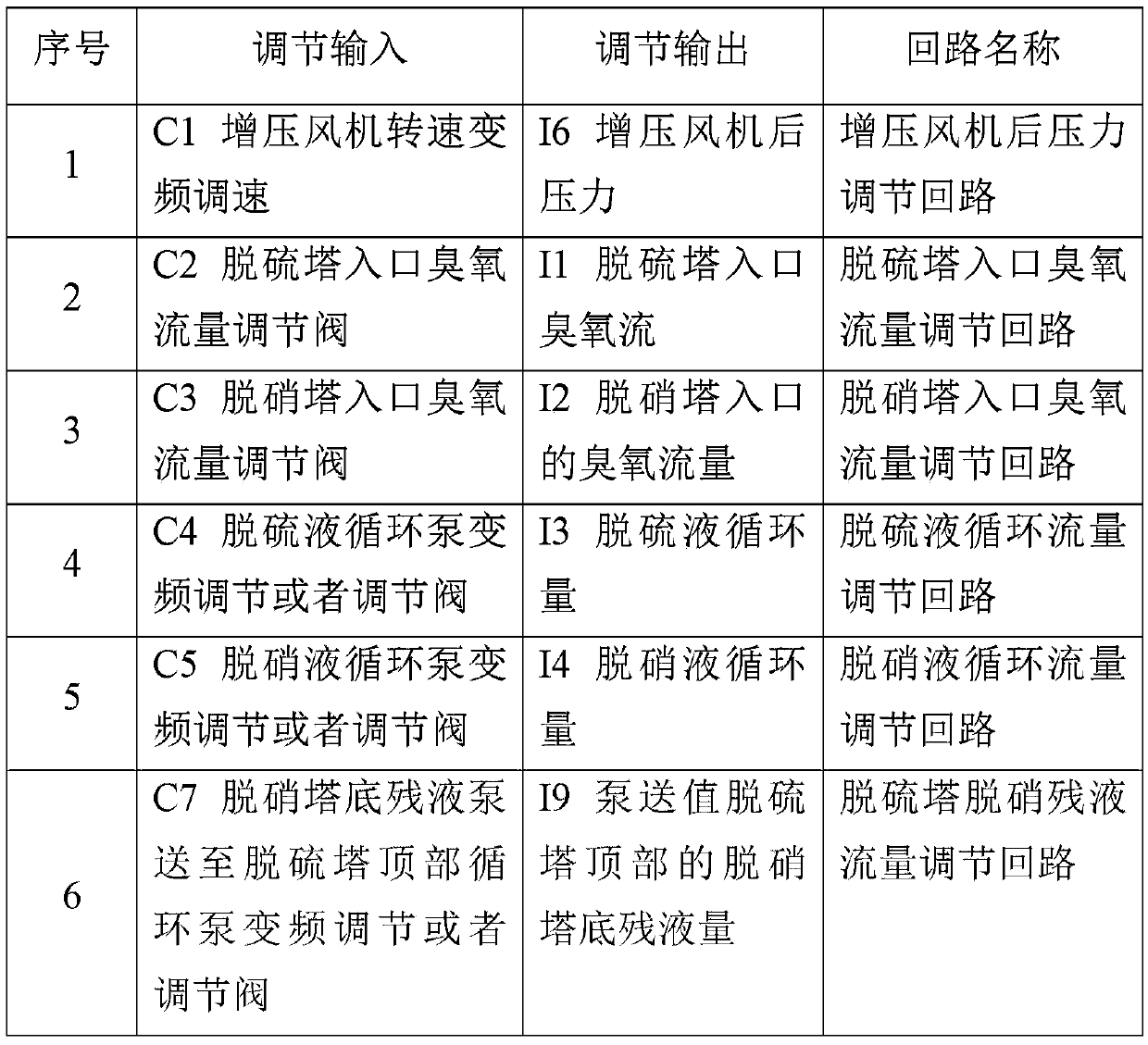

[0036] Such as figure 2 As shown, in the desulfurization and denitrification integrated equipment of the present invention, the relevant settings related to the control mode are as follows:

[0037] First, the process parameter detection instrument: the ozone flow detection device I1 at the entrance of the desulfurization tower; the ozone flow detection device I2 at the entrance of the denitrification tower; the detection device I3 for the circulation volume of desulfurization liquid; the detection device I4 for the circulation volume of denitrification liquid; The outlet pressure detection device I6 of the booster fan; the flue gas component detection device I7 at the inlet of the desulfurization tower (including NO, NO 2 and SO 2 Composition of the desulfurization tower storage tank oxidizing air inlet air pressure detection device I8; pumping value detection device I9 of residual liquid at the bottom of the denitration tower at the top of the desulfurization tower; compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com