Flue gas desulfurization and denitration system and method

A desulfurization, denitrification and flue gas technology, applied in the field of flue gas desulfurization and denitrification systems, can solve the problems of high cost, inability to flexibly adjust absorption temperature and absorption flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

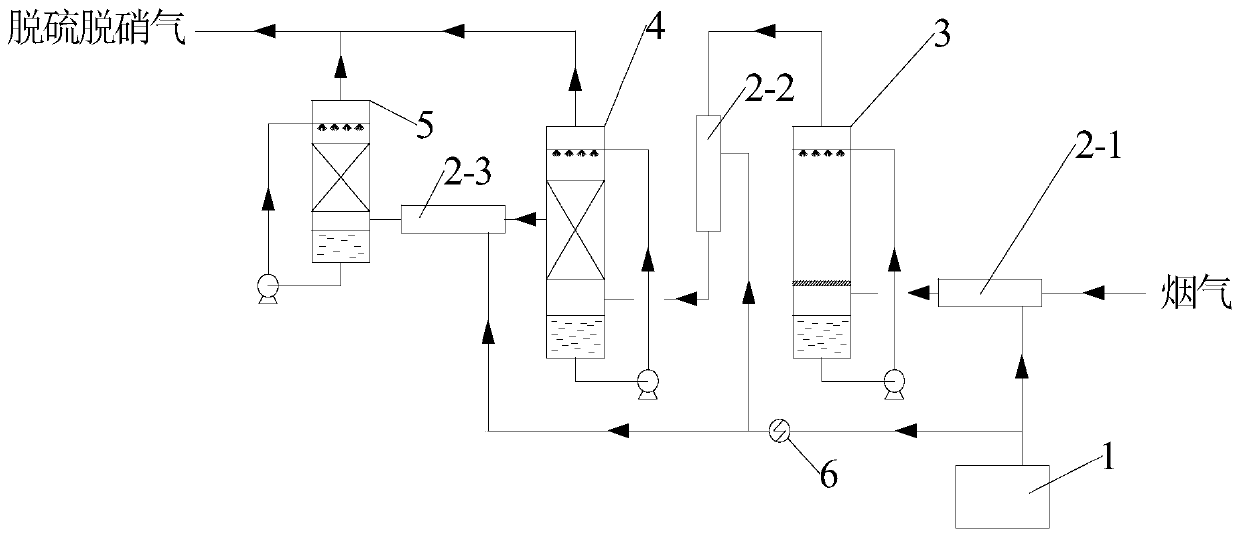

[0057] This embodiment provides a flue gas desulfurization and denitrification system, the structural diagram of the flue gas desulfurization and denitrification system is as follows figure 1 As shown, it includes desulfurization unit, denitrification unit and ozone generation unit.

[0058] The desulfurization unit includes a first mixing device 2-1 and a desulfurization tower 3 connected in sequence, and the flue gas flows into the denitrification tower after passing through the first mixing device 2-1.

[0059] The denitration unit includes a second mixing device 2-2, a first denitration tower 4, a third mixing device 2-3 and a second denitration tower 5, and the gas outlet of the desulfurization tower 3 is connected with the second mixing device 2-2 in sequence. And the first denitration tower 4 is connected; the side outlet of the first denitration tower 4 is connected with the third mixing device 2-3 and the second denitration tower 5 in sequence. The side discharge of ...

Embodiment 2

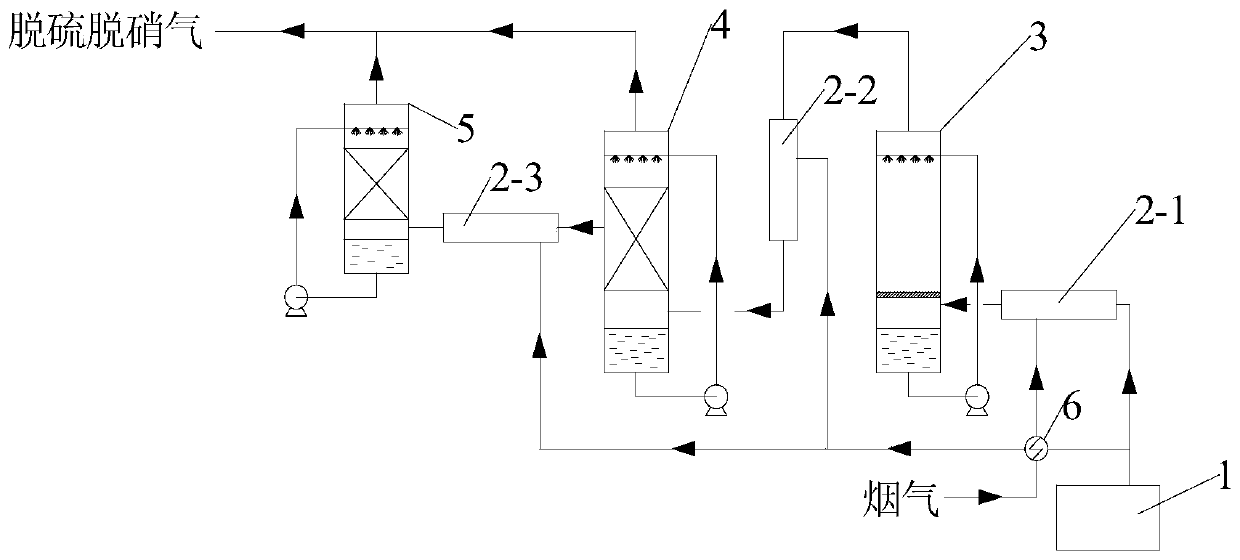

[0065] This embodiment provides a flue gas desulfurization and denitrification system, the structural diagram of the flue gas desulfurization and denitrification system is as follows figure 2 As shown, it includes desulfurization unit, denitrification unit and ozone generation unit.

[0066] The desulfurization unit includes a first mixing device 2-1 and a desulfurization tower 3 connected in sequence, and the flue gas flows into the denitrification tower after passing through the first mixing device 2-1.

[0067] The denitration unit includes a second mixing device 2-2, a first denitration tower 4, a third mixing device 2-3 and a second denitration tower 5, and the gas outlet of the desulfurization tower 3 is connected with the second mixing device 2-2 in sequence. And the first denitration tower 4 is connected; the side outlet of the first denitration tower 4 is connected with the third mixing device 2-3 and the second denitration tower 5 in sequence. The side discharge of...

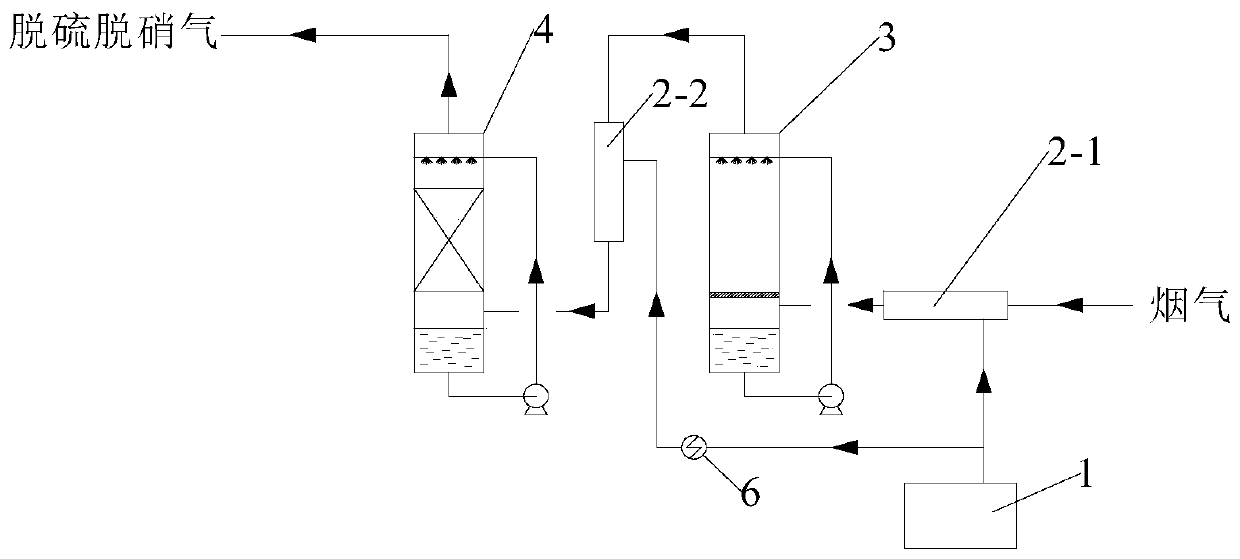

Embodiment 3

[0073] This embodiment provides a flue gas desulfurization and denitrification system, which is the same as that of Embodiment 1 except that the discharge position of the side line is at the bottom of the packing layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com