Flue gas denitrification device and method

A flue gas and denitrification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low denitration efficiency, high operation cost of denitration process, complicated equipment, etc., and achieve small footprint and operating cost. Low and high economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

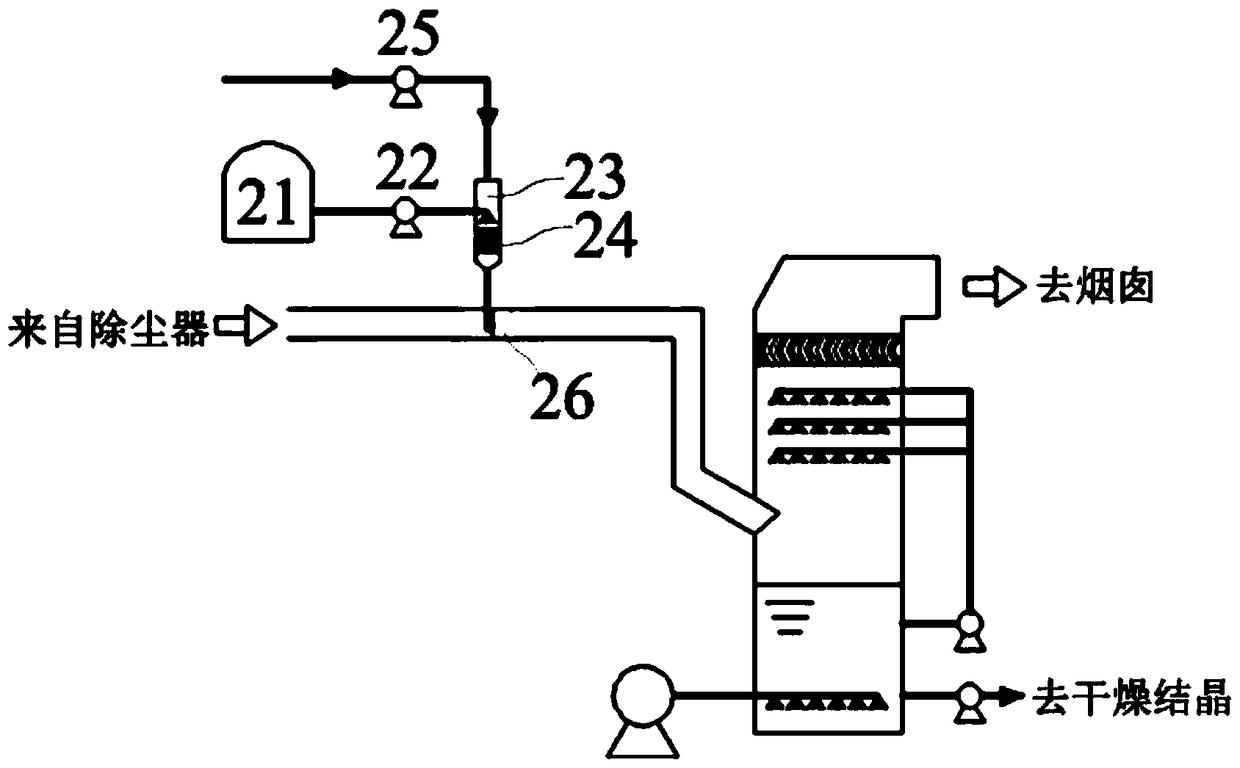

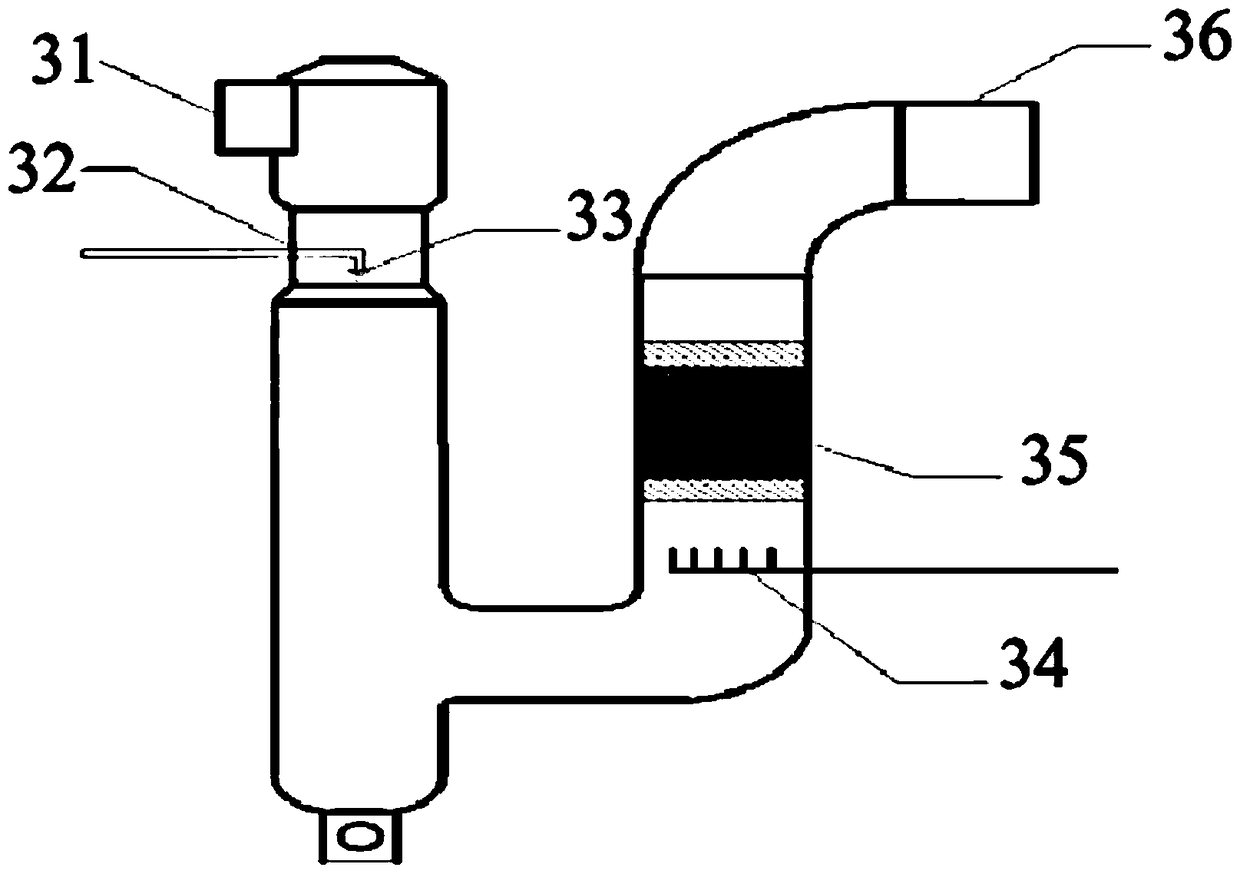

[0099]The flue gas oxidation step of the present invention is to use ozone and hydrogen peroxide to synergistically oxidize low-valent nitrogen oxides in the flue gas in the ozone spray oxidation reaction layer and hydrogen peroxide spray oxidation reaction layer to form high-valent nitrogen oxides. Preferably, the flue gas oxidation step of the present invention includes: in the ozone spray oxidation reaction layer, spray ozone downward through the ozone atomization spray part; in the hydrogen peroxide spray oxidation reaction layer, spray The shower unit sprays hydrogen peroxide downwards. The atomization and spraying process used in the flue gas oxidation step is not particularly limited, and those well known in the art can be used. According to one embodiment of the present invention, the flue gas oxidation step preferably uses stainless steel nozzles to spray ozone and hydrogen peroxide. The synergistic oxidation principle of ozone and hydrogen peroxide is as described a...

Embodiment 1

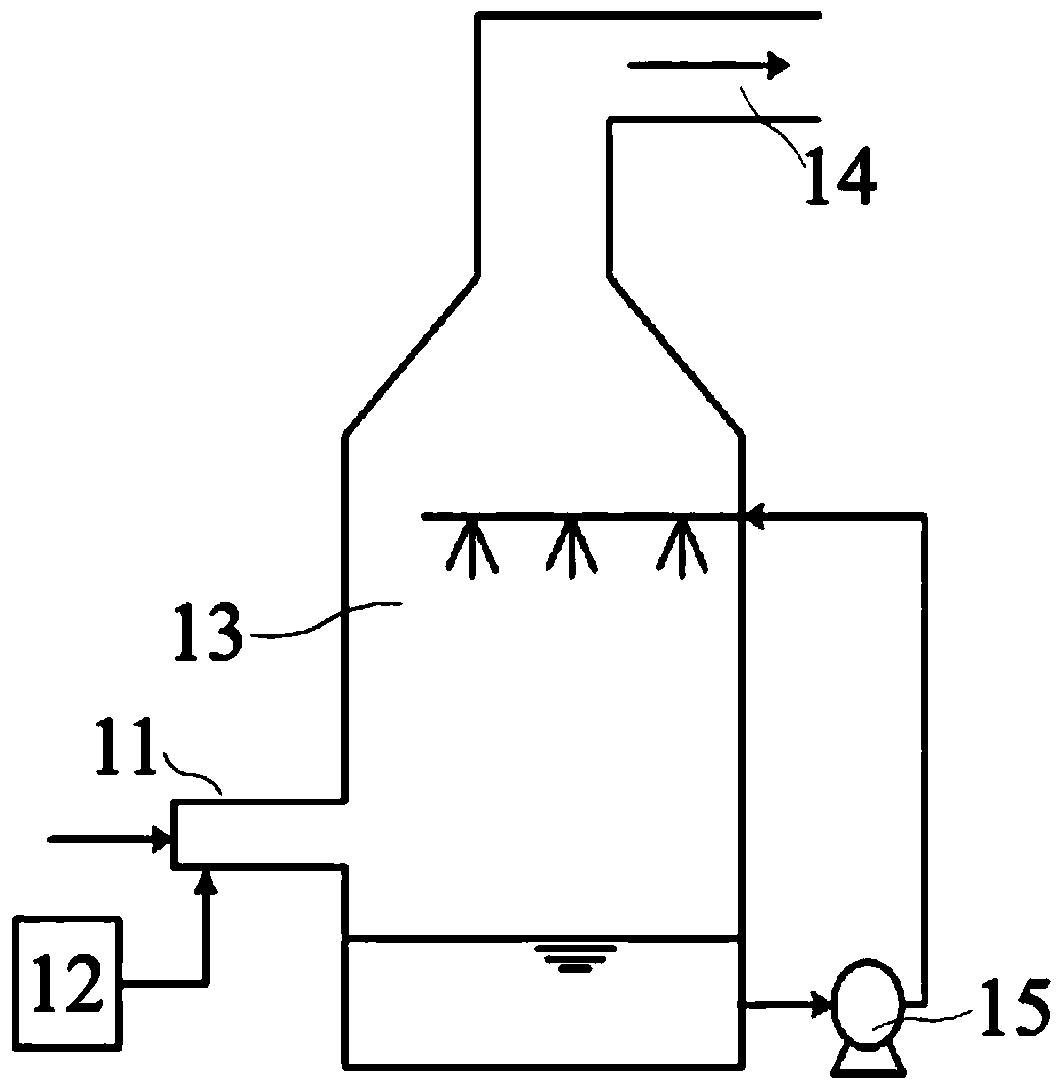

[0137] Pic 4-1A schematic diagram of the device of Example 1 of the present invention is shown. It can be seen from the figure that the flue gas denitrification device of the present invention includes a flue gas inlet 411 , flue gas denitrification equipment 41 , ozone supply equipment 45 , hydrogen peroxide supply equipment 48 and demister equipment 43 . Flue gas denitrification equipment 41 comprises ozone spray oxidation reaction layer 44, hydrogen peroxide spray oxidation reaction layer 47, absorption spray area 42 and slurry storage area 410, wherein, ozone spray oxidation reaction layer 44 and hydrogen peroxide spray oxidation reaction layer 47 They are all located in the absorption spray area 42. The absorption spray area 42 includes a first absorption spray layer 413 , a second absorption spray layer 414 and a third absorption spray layer 415 . The hydrogen peroxide spray oxidation reaction layer 47 is located between the first absorption spray layer 413 and the se...

Embodiment 2

[0150] Figure 4-2 A schematic diagram of the device of Example 2 of the present invention is shown. It can be seen from the figure that the flue gas denitrification device of the present invention includes a flue gas inlet 411 , flue gas denitrification equipment 41 , ozone supply equipment 45 , hydrogen peroxide supply equipment 48 and demister equipment 43 . Flue gas denitrification equipment 41 comprises ozone spray oxidation reaction layer 44, hydrogen peroxide spray oxidation reaction layer 47, absorption spray area 42 and slurry storage area 410, wherein, ozone spray oxidation reaction layer 44 and hydrogen peroxide spray oxidation reaction layer 47 They are all located in the absorption spray area 42. The absorption spray area 42 includes a first absorption spray layer 413 , a second absorption spray layer 414 and a third absorption spray layer 415 . The ozone spray oxidation reaction layer 44 is located between the first absorption spray layer 413 and the second abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com