A fluidized bed ozone oxidation tower

A fluidized bed and oxidation tower technology, applied in the field of fluidized bed ozone oxidation towers, can solve the problems of restricting the application of the ozone oxidation method, low ozone utilization rate, and high treatment cost, so as to reduce the cost of sewage treatment, improve the utilization rate, The effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

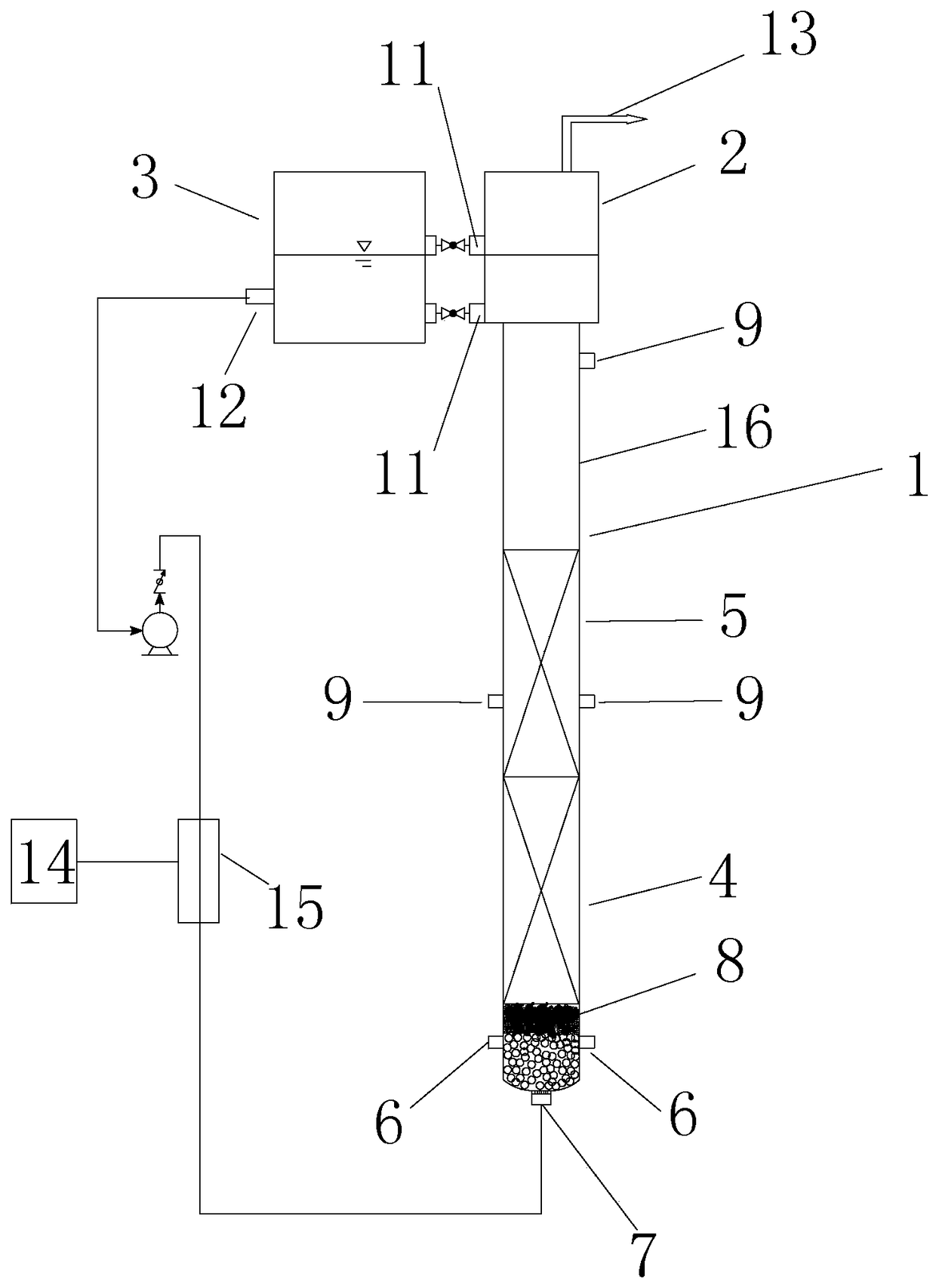

[0028] The specific implementation manners in the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, the fluidized bed ozonation tower of the present invention comprises: a tower body 1 (preferably a corrosion-resistant carbon steel material), a water outlet tank 2 arranged at the top of the tower body, a reflux tank 3 communicated with the water outlet tank 2 and Ozone device 14;

[0030] Among them, the bottom of the tower body 1 is provided with a sewage water inlet 6 (a coarse screen is provided at the sewage water inlet); the interior of the tower body 1 is divided into a water flow adjustment area 8, a fluidized bed filling area 4, and a fluidized bed reaction area from bottom to top. The expansion zone 5 and the reaction buffer outlet zone 16; the water flow adjustment zone 8 is provided with a water flow adjustment device, and the fluidized bed filling zone 4 is filled with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com