System and process for treating organic waste gas with micro-nano oxygen bubbles and iron ions

A technology of micro-nano bubbles and organic waste gas, which is applied in the direction of gas treatment, separation methods, and separation of dispersed particles, which can solve the problems of difficult decomposition of organic waste gas, secondary environmental pollution, and large reaction consumption, so as to achieve low reaction consumption and equipment reduction. The effect of energy consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose and technical solution of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

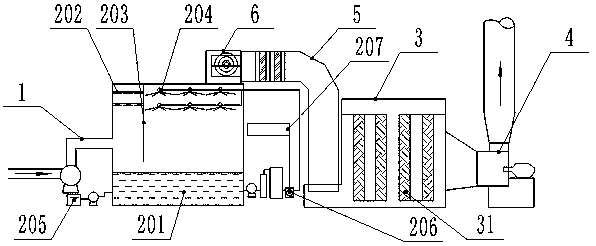

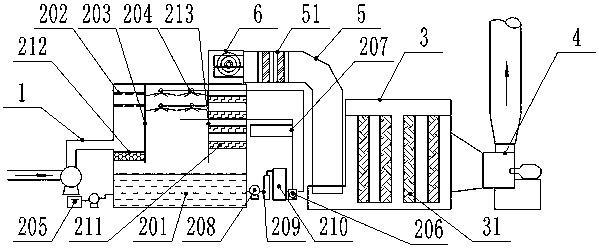

[0042] Such as figure 1 As shown, a system for treating organic waste gas with micro-nano oxygen bubbles in cooperation with iron ions according to the present invention includes an air intake device 1, a micro-nano oxygen bubble generating device, an adsorption purifier 3 and an exhaust device 4 connected in sequence;

[0043] The bottom of the micro-nano oxygen bubble generating device is provided with a water storage tank 201, and a sewage outlet is arranged in the water storage tank 201, which is used for liquid sewage in the water storage tank, and the water storage tank 201 is regularly cleaned.

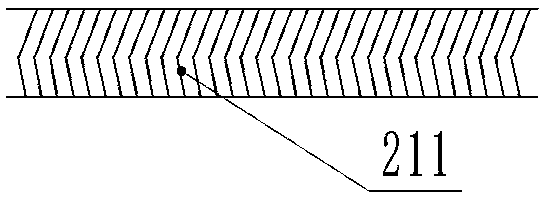

[0044] The side wall of the micro-nano oxygen bubble generating device is connected to the exhaust gas inlet of the air intake device 1; the micro-nano oxygen bubble generati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com