Water treatment device and method for reinforcing ozone mass transfer and oxidation process

A technology of water treatment device and oxidation process, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of ozone mass transfer and low efficiency of oxidation process, and achieve the solution of ozone selective oxidation , reduce the resistance of transmission, and improve the effect of ozone concentration gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

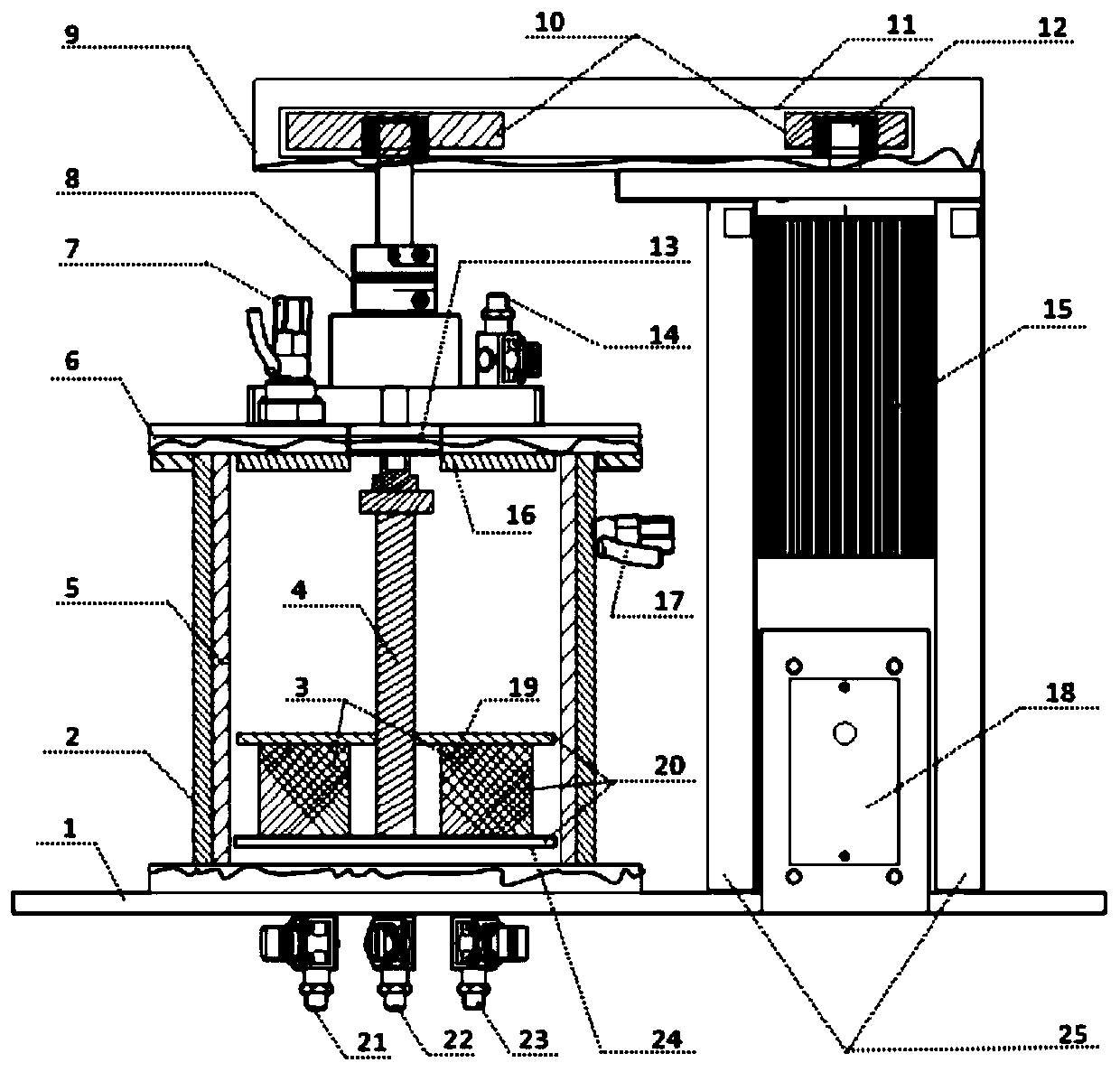

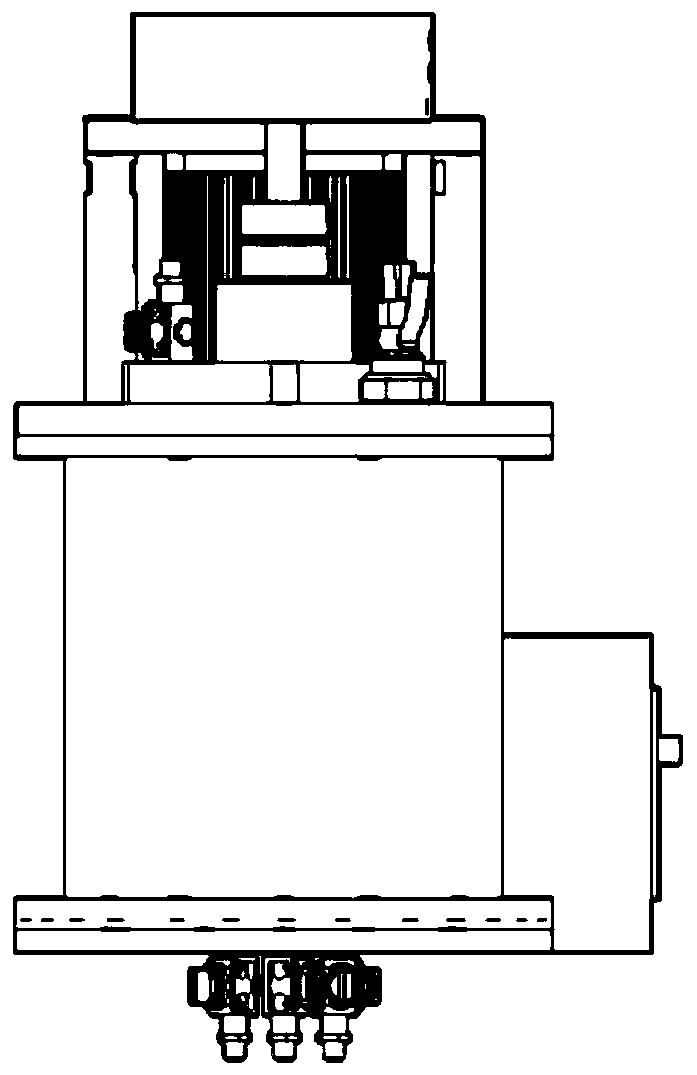

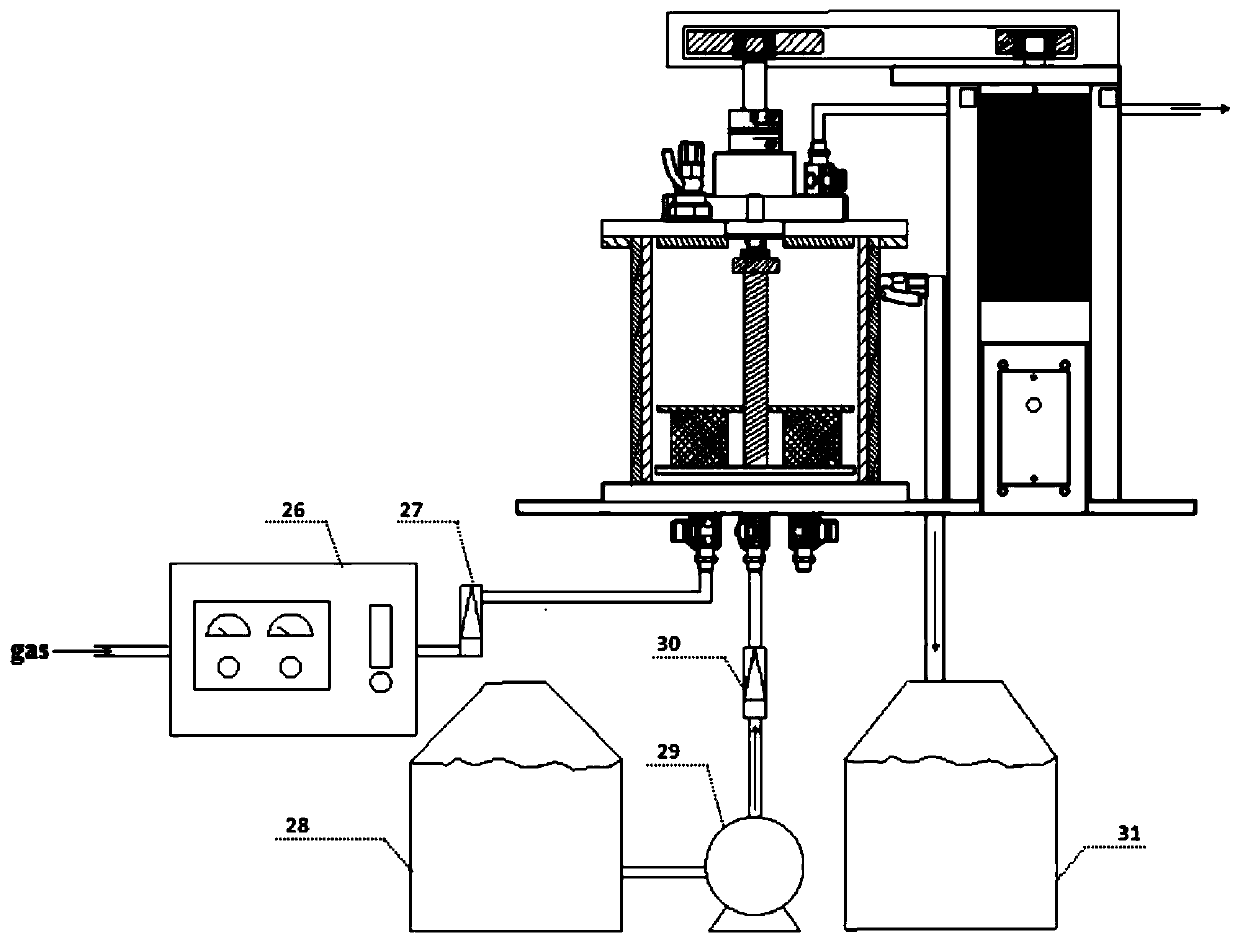

[0035] Such as image 3 , a water treatment device for enhancing ozone mass transfer and oxidation process in this embodiment, comprising an ozone generator, an inlet liquid storage tank, a reactor and a waste liquid storage tank;

[0036] The reactor includes a base, a shell, a rotating device, a transmission device, and a motor assembly;

[0037] The housing is arranged on the base, and several gas-liquid inlets and outlets are opened in the housing; several baffles are longitudinally arranged on the inner wall of the housing, and a top cover is provided on the top of the housing, and the top cover is surrounded by the housing and the base to form a seal. The lower surface of the top cover is equipped with several retaining strips at equal angles, and the retaining strips extend axially from the center of the top cover to the surroundings; the rotating device is arranged in the housing, including a rotating shaft and a rotor. The rotating shaft is erected at the center of t...

Embodiment 2

[0052] In this example, Acid Red B was used to simulate printing and dyeing wastewater, and the simulated wastewater was treated in a continuous operation mode. Porous foam filler adopts foam ceramics (Al 2 o 3 ) material, and the plated catalyst is an iron-cobalt double metal oxide. The simulated waste water is pumped into the reactor from the storage tank 28 , and the treated liquid enters the storage tank 31 . Set the ozone concentration to 20mg / L, and the gas-liquid flow ratio to 0.5-1. The speed is set at 300-500rpm.

[0053] The results showed that the removal rate of Acid Red B increased with the increase of rotational speed, and the removal rate did not increase significantly when it reached 500 rpm. The larger the gas-liquid ratio, the higher the removal rate of acid red B. Compared with the foam packing without catalyst plating, the removal rate of acid red B can be increased by about 10%. Under the optimal operating conditions, the removal rate of acid red B c...

Embodiment 3

[0055] In this embodiment, the swimming pool water sample is stored in the liquid inlet storage tank 28, wherein the urea content in the water sample is 10.23mg / L, and the total number of bacterial colonies is 5.4×10 4 cfu / mL, total coliform bacteria 230MPN / L. This embodiment is carried out in a continuous operation mode, and the ozone concentration is set at 10mg / L, the gas-liquid flow ratio is 0.2-0.6, and the rotation speed is 200-500rpm.

[0056] The results showed that with the increase of rotational speed and gas-liquid ratio, the removal rate of urea increased, and the total number of colonies and total coliforms decreased. Under the optimal operating conditions, the urea removal rate reaches 93%, the total number of colonies is less than 1cfu / mL, and the total coliform group is less than 3MPN / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com