Advanced treatment process for biochemical effluent in centralized sewage treatment plant

A sewage treatment plant, biochemical water effluent technology, applied in the direction of adsorption water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low processing capacity, short service life, difficult regeneration, etc., to achieve The process is easy to operate and the effect of less ozone consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

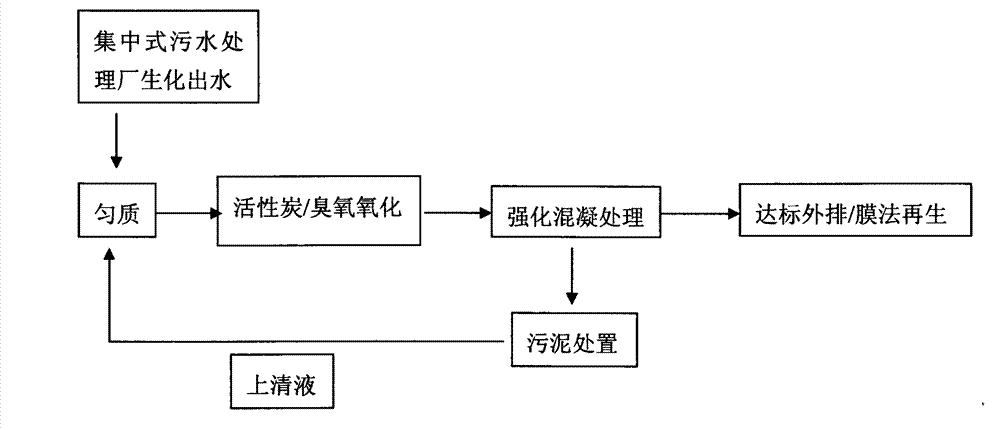

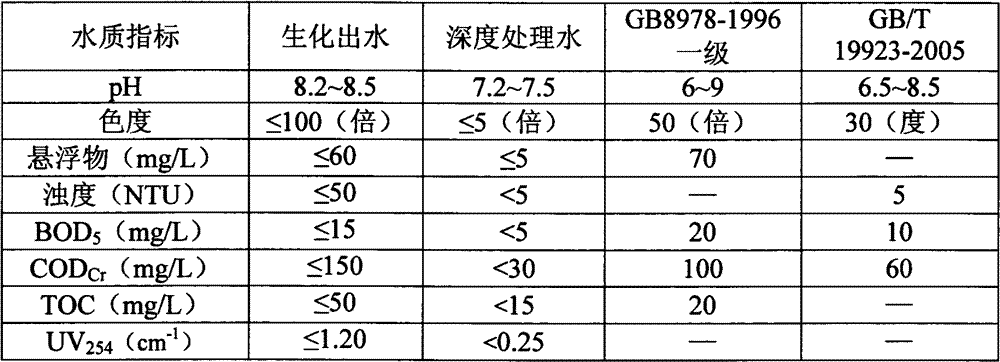

[0027] Water intake of a centralized sewage treatment plant in an industrial area (10000m 3 60% of / d) is wastewater produced by printing and dyeing, chemical and pharmaceutical companies, and the rest is domestic wastewater. After effective biochemical treatment (A / O process), the sewage still contains a certain amount of organic pollutants. The specific water quality is shown in Table 1. The specific process is shown in the appendix of the manual figure 1 .

[0028] After the biochemical effluent is homogenized for 1 hour in the regulating tank (water temperature is about 25°C), it is pumped into the activated carbon / ozone oxidation tower. Gas-liquid reverse contact reaction, granular activated carbon (specific performance indicators: particle diameter 3-5mm, iodine value about 2088mg / g, phenol value about 82.2mg / g, zero point potential about 7.4) (dosing per unit reactor volume (L) 20g) is in a fluidized state under the action of air flow (unit reactor volume (L) 300L (a...

Embodiment 2

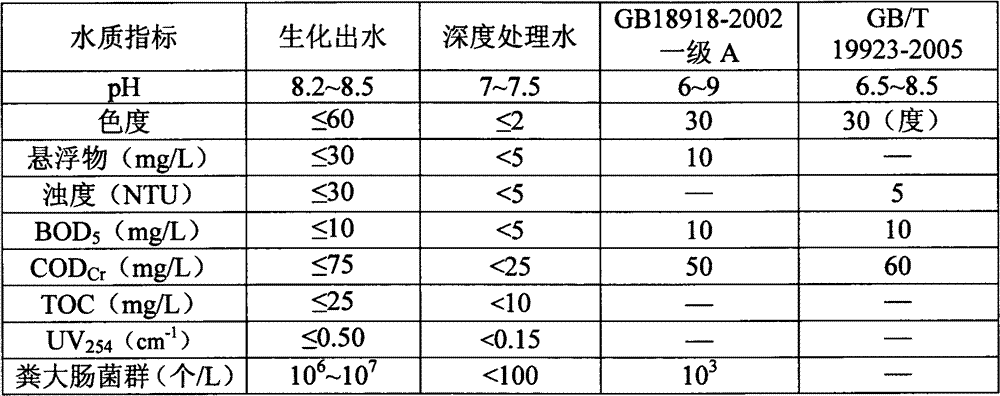

[0034] An urban sewage treatment plant adopts the oxidation ditch process for biochemical treatment, and the quality of biochemical effluent is shown in Table 2.

[0035] After the biochemical effluent is homogenized for 1 hour in the regulating tank (water temperature is about 25°C), it is pumped into the activated carbon adsorption / ozone oxidation tower (ozone contact reactor). Gas-liquid reverse contact reaction, granular activated carbon (specific performance indicators: particle diameter 3-5mm, iodine value about 2088mg / g, phenol value about 82.2mg / g, zero point potential about 7.4) (dosing per unit reactor volume (L) 15g) is in a fluidized state under the action of air flow (unit reactor volume (L) 300L (air) / h), the hydraulic retention time is controlled at 2min, and the ozone concentration is adjusted to 5mg / Nm 3 . Oxidation treatment effluent is mixed with aluminum sulfate (25mg / L, as Al 3+ meter) mixed with a certain amount of sulfuric acid, the pH was adjusted to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com