Advanced treatment process for biochemical effluent in centralized sewage treatment plant

A sewage treatment plant, biochemical water effluent technology, applied in the direction of water/sewage multi-stage treatment, adsorption water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of low treatment capacity, short service life, difficult regeneration, etc., to achieve The effect of less ozone consumption and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

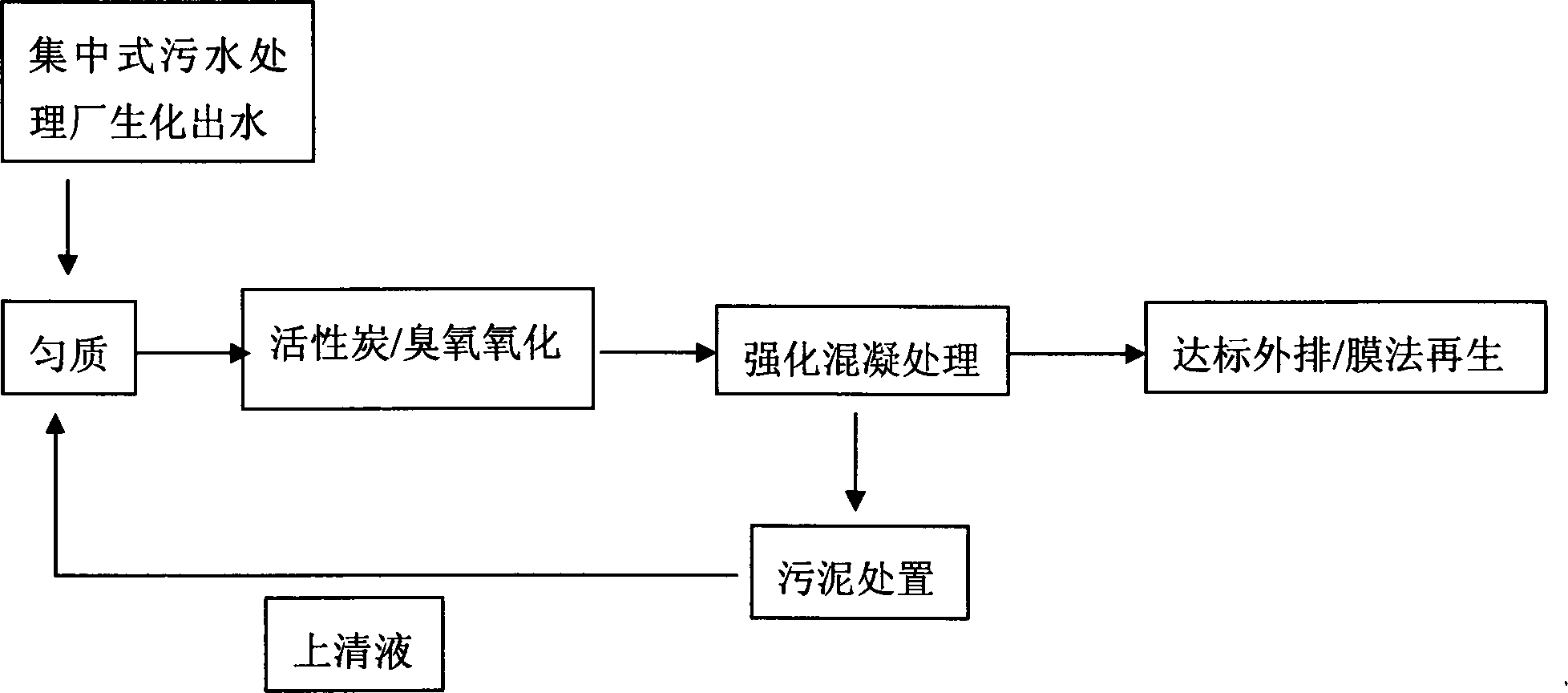

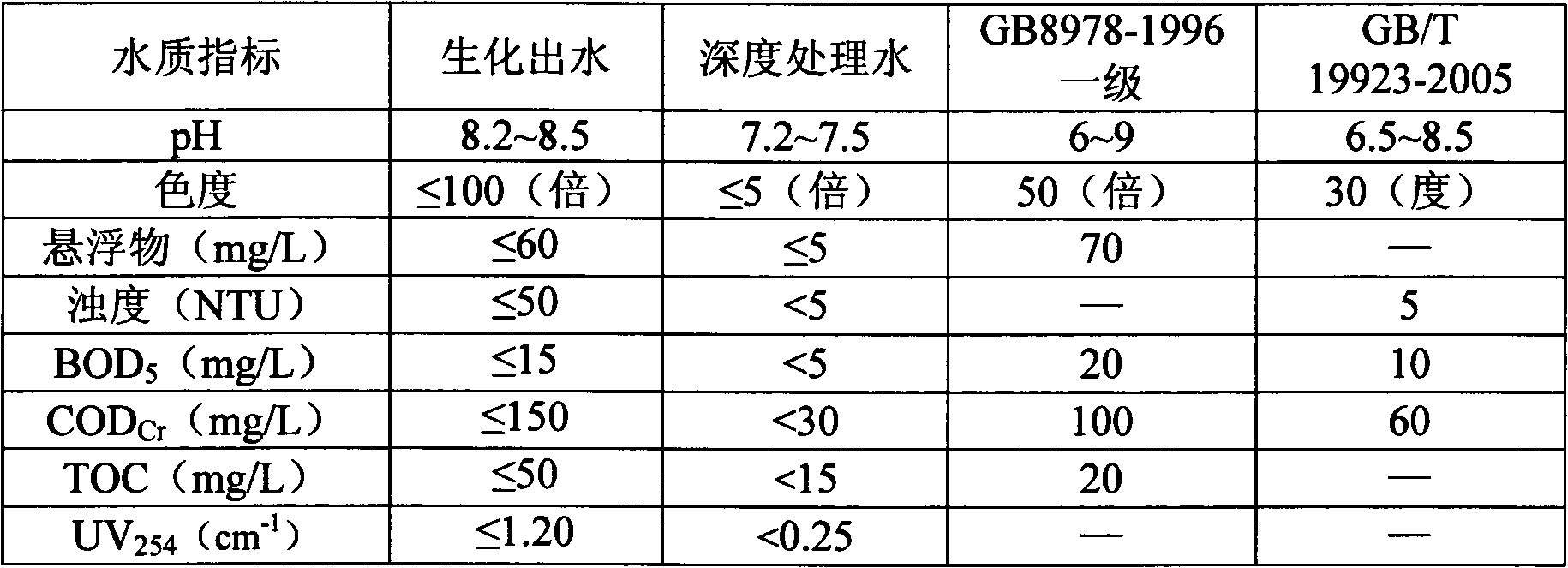

[0027] Water intake of a centralized sewage treatment plant in an industrial area (10000m 3 60% of / d) is wastewater produced by printing and dyeing, chemical and pharmaceutical companies, and the rest is domestic wastewater. After effective biochemical treatment (A / O process), the sewage still contains a certain amount of organic pollutants. The specific water quality is shown in Table 1. The specific process is shown in the appendix of the manual figure 1 .

[0028] After the biochemical effluent is homogenized for 1 hour in the regulating tank (water temperature is about 25°C), it is pumped into the activated carbon / ozone oxidation tower. Gas-liquid reverse contact reaction, granular activated carbon (specific performance indicators: particle diameter 3-5mm, iodine value about 2088mg / g, phenol value about 82.2mg / g, zero point potential about 7.4) (dosing per unit reactor volume (L) 20g) is in a fluidized state under the action of air flow (unit reactor volume (L) 300L (a...

Embodiment 2

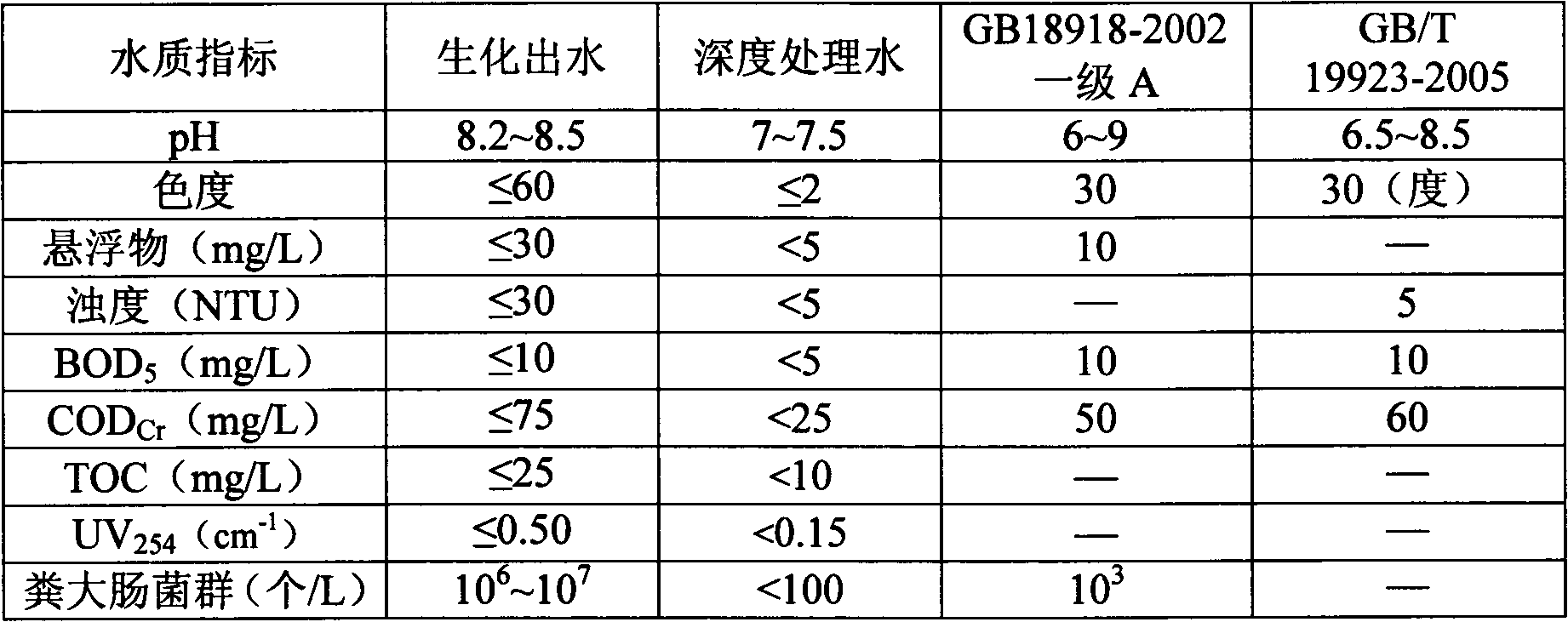

[0034] An urban sewage treatment plant adopts the oxidation ditch process for biochemical treatment, and the quality of biochemical effluent is shown in Table 2.

[0035] After the biochemical effluent is homogenized for 1 hour in the regulating tank (water temperature is about 25°C), it is pumped into the activated carbon adsorption / ozone oxidation tower (ozone contact reactor). Gas-liquid reverse contact reaction, granular activated carbon (specific performance indicators: particle diameter 3-5mm, iodine value about 2088mg / g, phenol value about 82.2mg / g, zero point potential about 7.4) (dosing per unit reactor volume (L) 15g) is in a fluidized state under the action of air flow (unit reactor volume (L) 300L (air) / h), the hydraulic retention time is controlled at 2min, and the ozone concentration is adjusted to 5mg / Nm 3 . Oxidation treatment effluent is mixed with aluminum sulfate (25mg / L, as Al 3+ meter) mixed with a certain amount of sulfuric acid, the pH was adjusted to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com