Microbubble ozonation-thin layer drying combined treatment device and method for excess sludge

A technology of excess sludge and ozone oxidation, which is applied in dewatering/drying/concentrating sludge treatment, sludge treatment, biological sludge treatment, etc. problems, to achieve the effect of improving ozone utilization, reducing sludge discharge and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

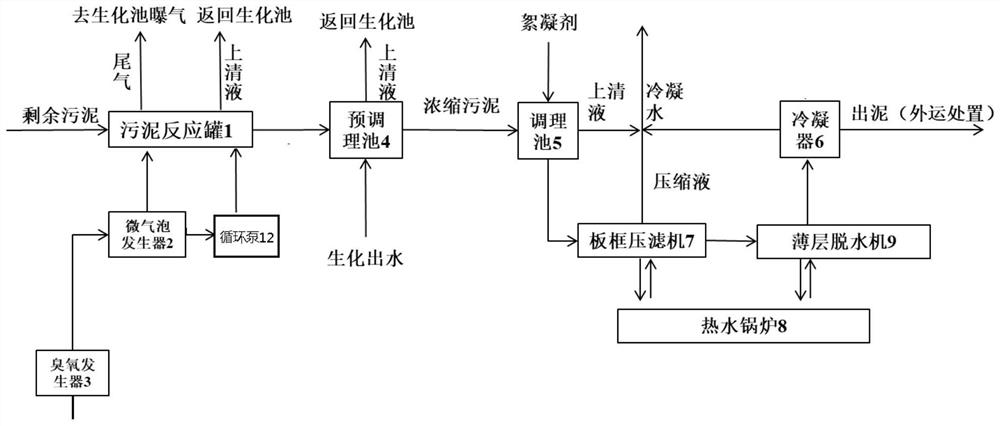

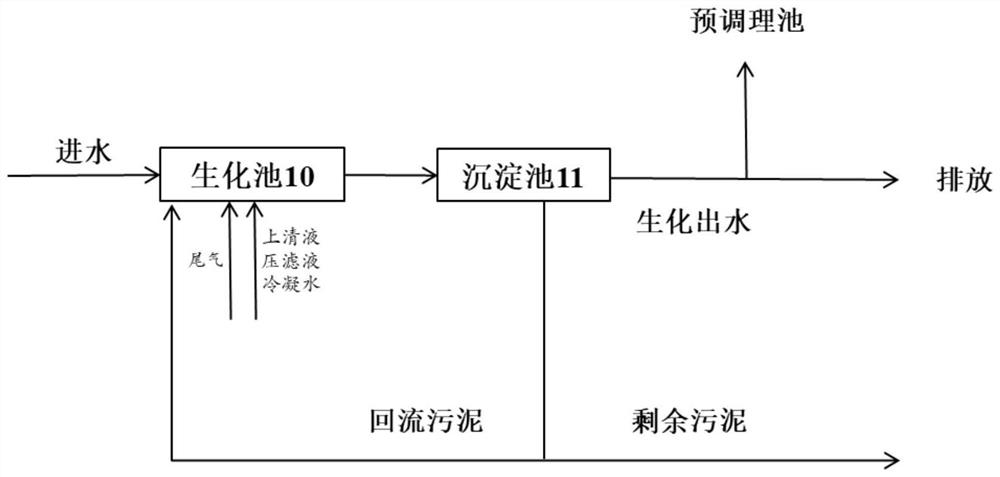

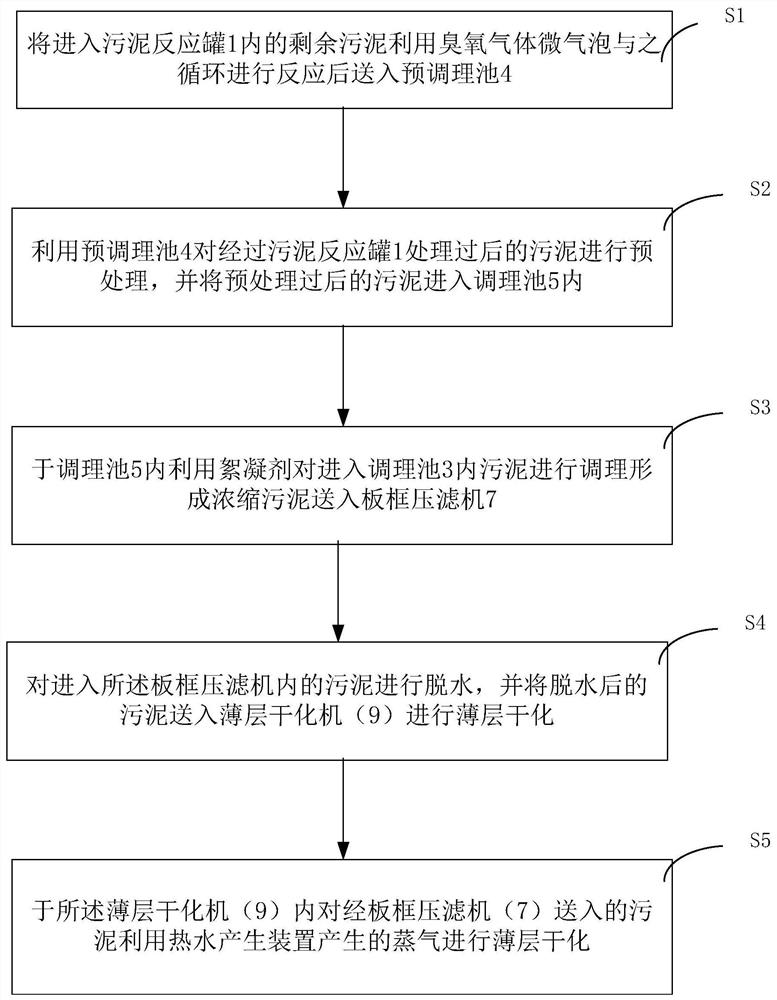

[0061] Embodiment 1: Through the mud inlet pipe, the remaining sludge with a moisture content of about 99% is passed in the sludge reaction tank 1, and it is allowed to stay in the sludge reaction tank 1 for 2 hours. The amount of ozone added and the quality of the sludge The ratio range is about 1:400. After the aeration is over, the tail gas enters the biochemical tank through the gas pipeline for aeration, the remaining sludge is separated from the mud and water, and the supernatant is returned to the biochemical tank through the pipeline. The aerated sludge enters the pre-conditioning tank 4 through the pipeline, and is washed with the effluent of the biochemical tank. After the elutriation, the sludge is separated from the mud and water, and the supernatant is returned to the biochemical tank through the pipeline. The preconditioned sludge enters the conditioning tank 5 through the pipeline, and is conditioned by adding flocculants. After conditioning, the sludge is sep...

Embodiment 2

[0062] Embodiment 2: Through the mud inlet pipe, the remaining sludge with a moisture content of about 99.5% is passed in the sludge reaction tank 1, so that it stays in the sludge reaction tank 1 for 3 hours, the amount of ozone dosage and the quality of the sludge The ratio range is about 1:800. After the aeration is over, the tail gas enters the biochemical tank through the gas pipeline for aeration, the remaining sludge is separated from the mud and water, and the supernatant is returned to the biochemical tank through the pipeline. The aerated sludge enters the pre-conditioning tank 4 through the pipeline, and is washed with the effluent of the biochemical tank. After the elutriation, the sludge is separated from the mud and water, and the supernatant is returned to the biochemical tank through the pipeline. The preconditioned sludge enters the conditioning tank 5 through the pipeline, and is conditioned by adding flocculants. After the conditioning, the sludge is separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com