Gas-solid phase continuous reaction device with heat transfer enhancing function

A technology for strengthening heat transfer and reaction devices, applied in chemical/physical/physical-chemical fixed reactors, feeding devices, chemical instruments and methods, etc., can solve problems such as inability to achieve continuous operation, and improve equipment utilization. , avoid manual operation, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

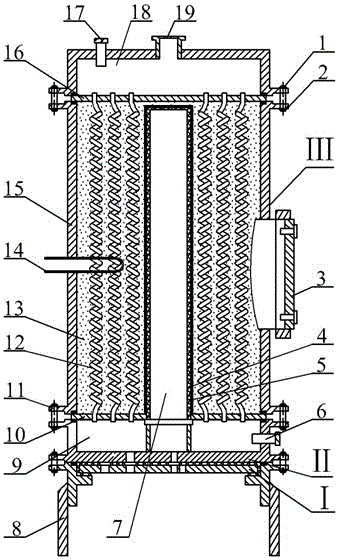

[0044] Aiming at the hydrogen absorption and desorption process of metal hydride hydrogen storage reaction, the structural schematic diagram of the present invention is as attached Figure 1-4 shown. The present invention will be further described below in conjunction with the accompanying drawings.

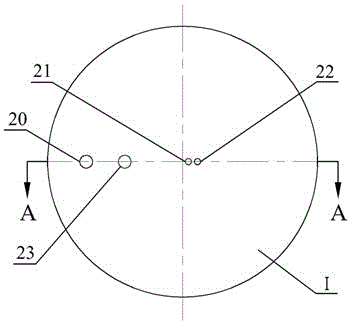

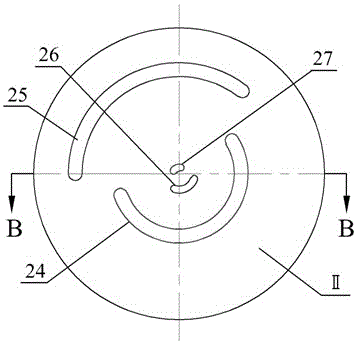

[0045] attached Figure 1-3 As shown, the cooling fluid inlet (20), the hot fluid inlet (23), the gas phase inlet (21) and the gas phase outlet (22) are arranged radially on the rotating disk (I), and the cooling fluid inlet (22) is arranged on the fixed disk (II) according to certain rules. Fluid inlet groove (25), thermal fluid inlet groove (24), gas phase inlet groove (27) and gas phase outlet groove (26), the distance between each gas phase and fluid inlet and outlet groove (24, 25, 26, 27) and the center of the disk It is equal to the distance from the corresponding hole on the rotating disk to the center of the disk, and the groove width is equal to the diameter of the co...

Embodiment 2

[0053] For the hydrogen storage reaction that requires vacuuming and ensuring pressure safety, the inventor added a vacuuming passage and a safety valve passage on the basis of the four-hole solution in Example 1 to further ensure the thoroughness and safety of the reaction. Attached below Figure 5-8 The present invention will be further described by taking the complete hydrogen storage reaction process as an example.

[0054] When the rotating disk is turned until the vacuum port (29) is connected to the vacuum groove (30) of the fixed disk (II), gas phase desorption or desorption under vacuum conditions can be realized, and the residual in the device can also be extracted before the initial reaction. gas.

[0055] as attached Image 6 , 7 As shown, a safety valve interface (28) is added on the rotating disk (Ⅰ), which can be connected with a safety valve and a pressure gauge. When the rotating disk rotates to the safety valve interface (28) and the safety valve interface...

Embodiment 3

[0063] The inventor used the commercial simulation software COMSOL to establish a three-dimensional mathematical model of the present invention, and carried out detailed numerical calculations on its hydrogen absorption and desorption process, explored the influence of different initial reaction fractions on the reaction process, and obtained the optimal initial reaction The optimal scheme of the hydrogen absorption and desorption cycle duration under the fractional ratio and the length of each channel on the fixed plate corresponding to each stage. as follows:

[0064] attached Figure 9 It is the time-consuming distribution diagram of the hydrogen absorption and desorption reaction of the device under different initial reaction fractions. The degree of control reaction is certain, that is, △X=0.8. It was found that, limited by the mechanism of hydrogen absorption and desorption reaction, the larger the initial reaction fraction of hydrogen absorption, the longer the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com