Multifunctional combination operation process and device for injection pump unit

A process device and multi-functional technology, which can be applied to pumps, mechanical equipment, machines/engines, etc., can solve the problems of unprotected oil well casing, high construction cost, long construction period, etc., to avoid formation pollution and environmental pollution, The effect of reducing the construction time and the number of constructions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

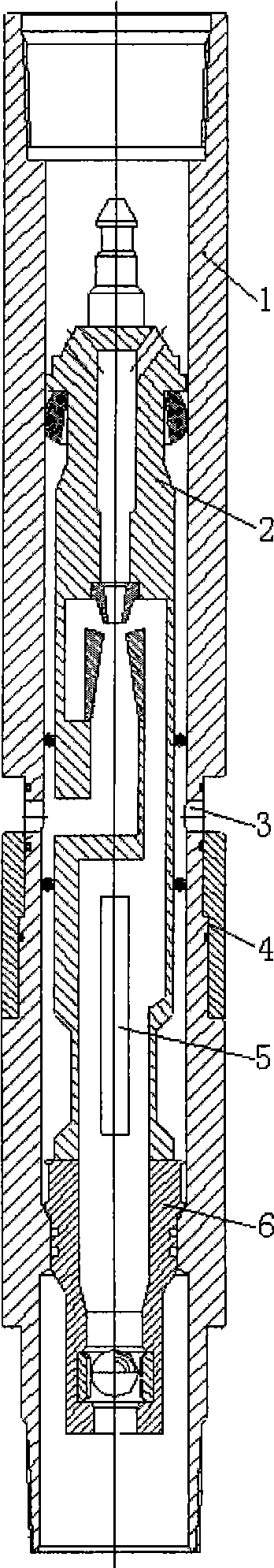

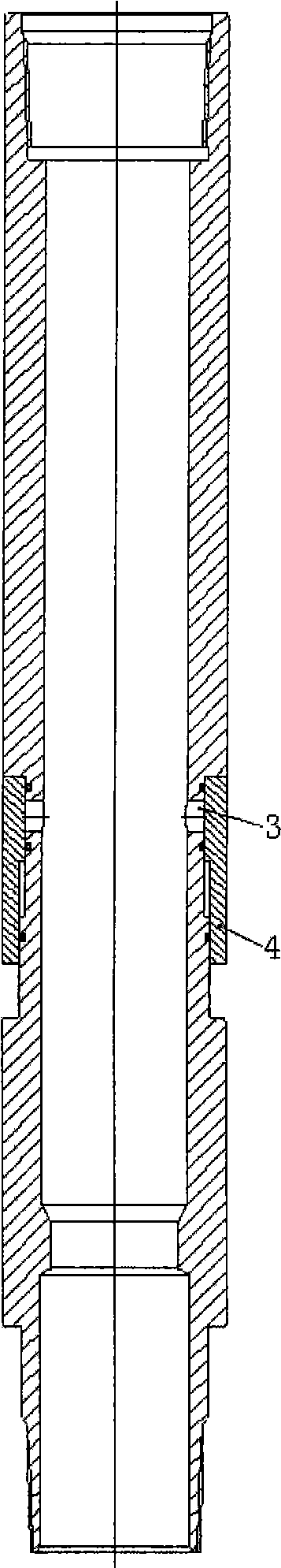

[0021] A jet pump unit multi-functional coupling process, comprising the following continuous steps: (A) running a designed pipe string into a well; (B) carrying out scraping, acidizing, fracturing, and liquid drainage test construction operations; (C) carrying out oil production or Water injection production is characterized in that the (B) step includes the following procedures: 1. Pull out the well pipe string, lower the scraper pipe string, and scrape the pipe within the range of 6-10m of the packer design setting position for 3-5 2. Run into the well to complete the jet pump unit multi-functional combined process device to the design position; 3. Carry out positive circulation treatment, inject pre-fluid or fracturing fluid from the tubing to the well bottom, close the casing valve, and enter the target treatment layer through the liquid flow channel and screen of the device when the tubing pressure is greater than the casing pressure; 4. Shut-in response; 5. Open the well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com