Spirofluorene copper pyridine micro-nano particle and preparation method thereof

A technology of micro-nano particles and copper spirofluorene pyridine, which is applied in the field of metal micro-nano particle catalysis, can solve the problems of no proposed catalytic coupling reaction efficiency, no in-depth research, etc., and achieves high reaction activity, strong delocalization, and broad application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 10mL of 10mmol / L copper nitrate aqueous solution and 10mL of 10mmol / L spirofluorenepyridine (tpsf for short) ethanol solution respectively, put them into a 50mL 19-necked Erlenmeyer flask, stir vigorously at 20°C for 10h, and age the blue suspension at room temperature 3h. The product obtained by the reaction was centrifuged, the clear liquid was discarded, and the remaining precipitate was washed three times with deionized water and ethanol respectively, ultrasonically dispersed, and dried to obtain spirofluorenpyridine copper micro-nano particles. The product was observed with a scanning electron microscope (SEM), see figure 1 , the product is flaky micro-nano crystals with a size of about 200-800nm.

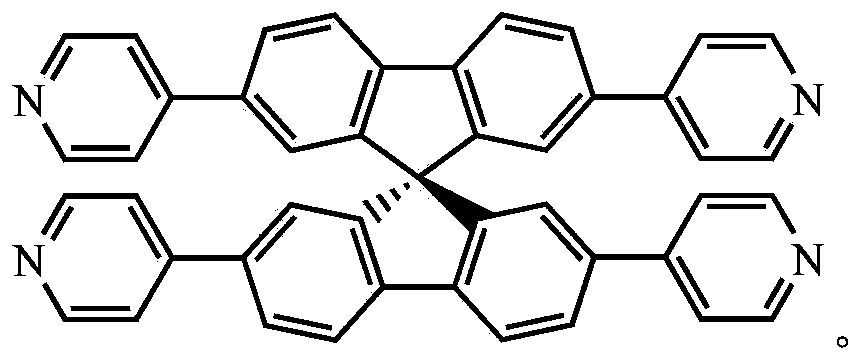

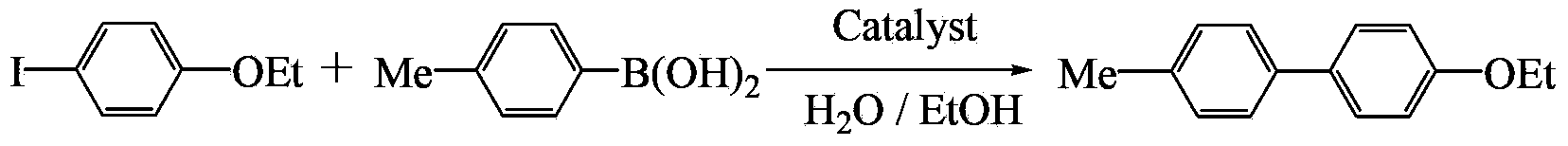

[0031] Wherein, the preparation method of the spirofluorenpyridine comprises: 2,2′,7,7′-tetrabromo-9,9′-spirobifluorene (3mmol, 1.91g), 4-pyridineboronic acid (9mmol, 1.12g ), potassium carbonate (20mmol, 2.76g), and toluene / ethanol / water (80mL / 40mL / 20mL) were ad...

Embodiment 2

[0033] Take 10mL of 100mmol / L copper chloride aqueous solution and 10mL of 25mmol / L tpsf dichloromethane solution respectively, place them in a 50mL 19-necked Erlenmeyer flask, stir vigorously at 80°C for 30min, and age the blue suspension at room temperature for 10h. The product obtained by the reaction was centrifuged, the clear liquid was discarded, and the remaining precipitate was washed three times with deionized water and ethanol respectively, ultrasonically dispersed, and dried to obtain spirofluorenpyridine copper micro-nano particles. The product was observed with a scanning electron microscope (SEM), see figure 1 , the product is a flaky nanocrystal with a size of about 200-800nm.

Embodiment 3

[0035] Take 10mL of 30mmol / L copper sulfate aqueous solution and 10mL of 20mmol / L tpsf ethanol solution respectively, place them in a 50mL 19-necked Erlenmeyer flask, stir vigorously at 50°C for 4h, and age the blue suspension at room temperature for 6h. Centrifuge the obtained product, discard the clear liquid, wash the remaining precipitate with deionized water and ethanol three times, ultrasonically disperse, and dry to obtain spirofluorenpyridine copper micro-nano particles with a size of about 200-800nm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com