Early strength concrete and preparation method thereof

A concrete and super early strength technology, applied in the field of concrete engineering, can solve problems such as road blockage, vehicle transportation interruption, long maintenance time, etc., and achieve the effect of improving early strength, improving reactivity, and developing well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

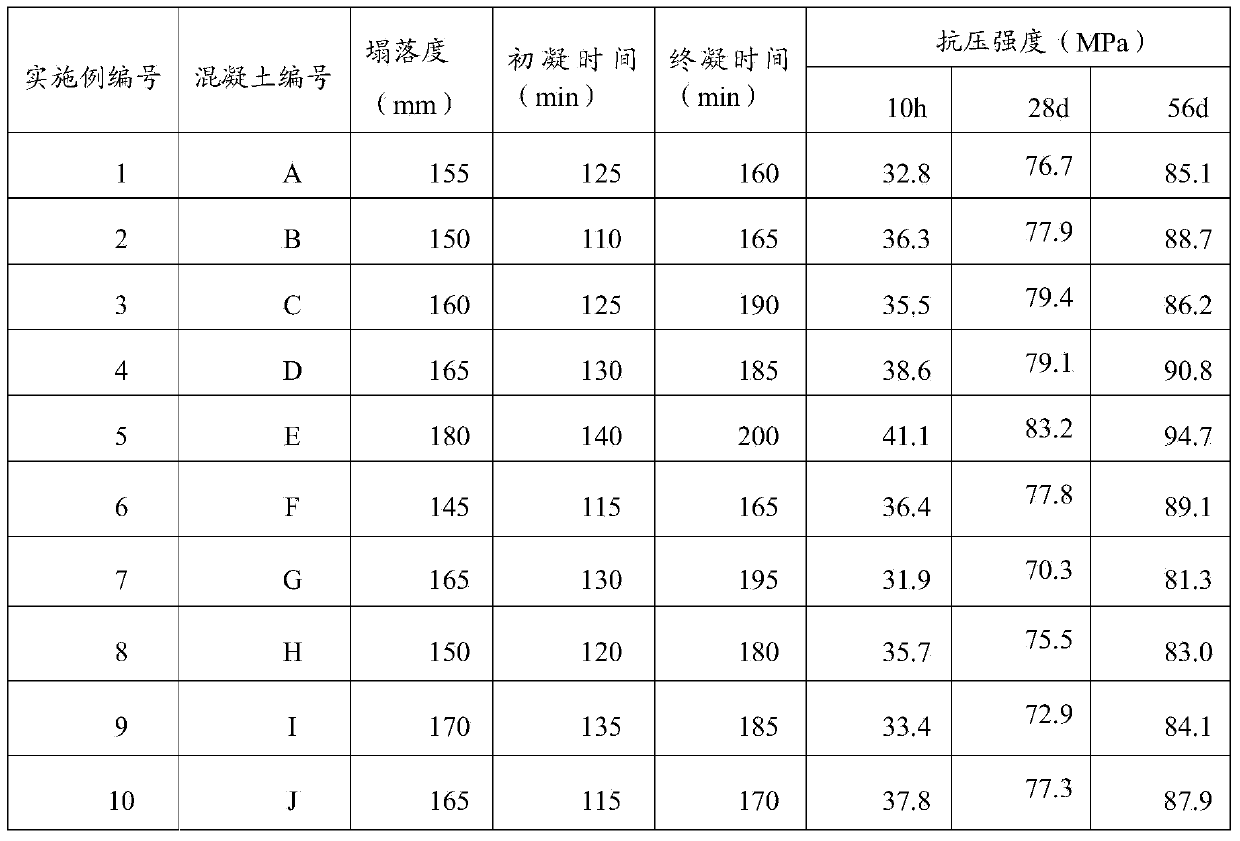

Examples

Embodiment 1

[0036]Calculated per cubic meter of super-early-strength concrete, the amount of raw materials added is: 470kg of cementitious material, of which 409kg for ordinary Portland cement P.O42.5 in the gelatinous material, 41kg for glass powder, and 20kg for silica fume , the aggregate is 1650kg, the sodium hydroxide in the composite activator is 0.47kg, the triethanolamine is 0.094kg, the polycarboxylate superplasticizer is 2.35kg, the water-binder ratio is 0.20, and the aggregate sand rate is 30%;

[0037] The preparation method of geopolymer concrete described in the present embodiment comprises the steps:

[0038] (1) adding the gelling material and sodium hydroxide into the mixer and stirring for 60s to obtain the gelling material mixture;

[0039] (2) Add a specific amount of aggregate to the uniformly stirred cementitious material mixture in the step (1), and stir for 30 seconds;

[0040] (3) Add triethanolamine, water reducing agent and water to the uniformly stirred mixtur...

Embodiment 2

[0042] Calculated per cubic meter of super early strength concrete, the amount of raw materials added is: 500kg of cementitious material, of which 420kg for ordinary Portland cement P.O42.5 in the gelatinous material, 50kg for glass powder, and 30kg for silica fume , the aggregate is 1680kg, the sodium hydroxide in the composite activator is 1.0kg, the triethanolamine is 0.15kg, the polycarboxylate superplasticizer is 5.0kg, the water-binder ratio is 0.22, and the aggregate sand rate is 31%;

[0043] The preparation method of geopolymer concrete described in the present embodiment comprises the steps:

[0044] (1) adding the gelling material and sodium hydroxide into the mixer, and stirring for 75s to obtain the gelling material mixture;

[0045] (2) Add a specific amount of aggregate to the uniformly stirred cementitious material mixture in the step (1), and stir for 34 seconds;

[0046] (3) Add triethanolamine, water reducing agent and water to the uniformly stirred mixture...

Embodiment 3

[0048] Calculated per cubic meter of super early strength concrete, the amount of raw materials added is: 530kg of cementitious material, of which 424kg for ordinary Portland cement P.O52.5 in the gelatinous material, 64kg for glass powder, and 42kg for silica fume , the aggregate is 1700kg, the sodium hydroxide in the composite activator is 1.59kg, the triethanolamine is 0.21kg, the polycarboxylate superplasticizer is 6.36kg, the water-binder ratio is 0.24, and the aggregate sand rate is 33%;

[0049] The preparation method of geopolymer concrete described in the present embodiment comprises the steps:

[0050] (1) adding the gelling material and sodium hydroxide into the mixer, and stirring for 70s to obtain the gelling material mixture;

[0051] (2) Add a specific amount of aggregate to the cementitious material mixture stirred uniformly in the step (1), and stir for 36 seconds;

[0052] (3) Add triethanolamine, water reducing agent and water to the uniformly stirred mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com