Catalytic cracking method and system for producing propylene and light aromatic hydrocarbons

A technology of catalytic cracking and light aromatics, which is applied in the direction of catalytic cracking, only multi-stage series cracking process treatment, hydrocarbon cracking and hydrocarbon production, etc. It can solve the problems of low reaction conversion rate and reduced coke yield, so as to improve reaction conversion efficiency, increased yield, product distribution and the effect of improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

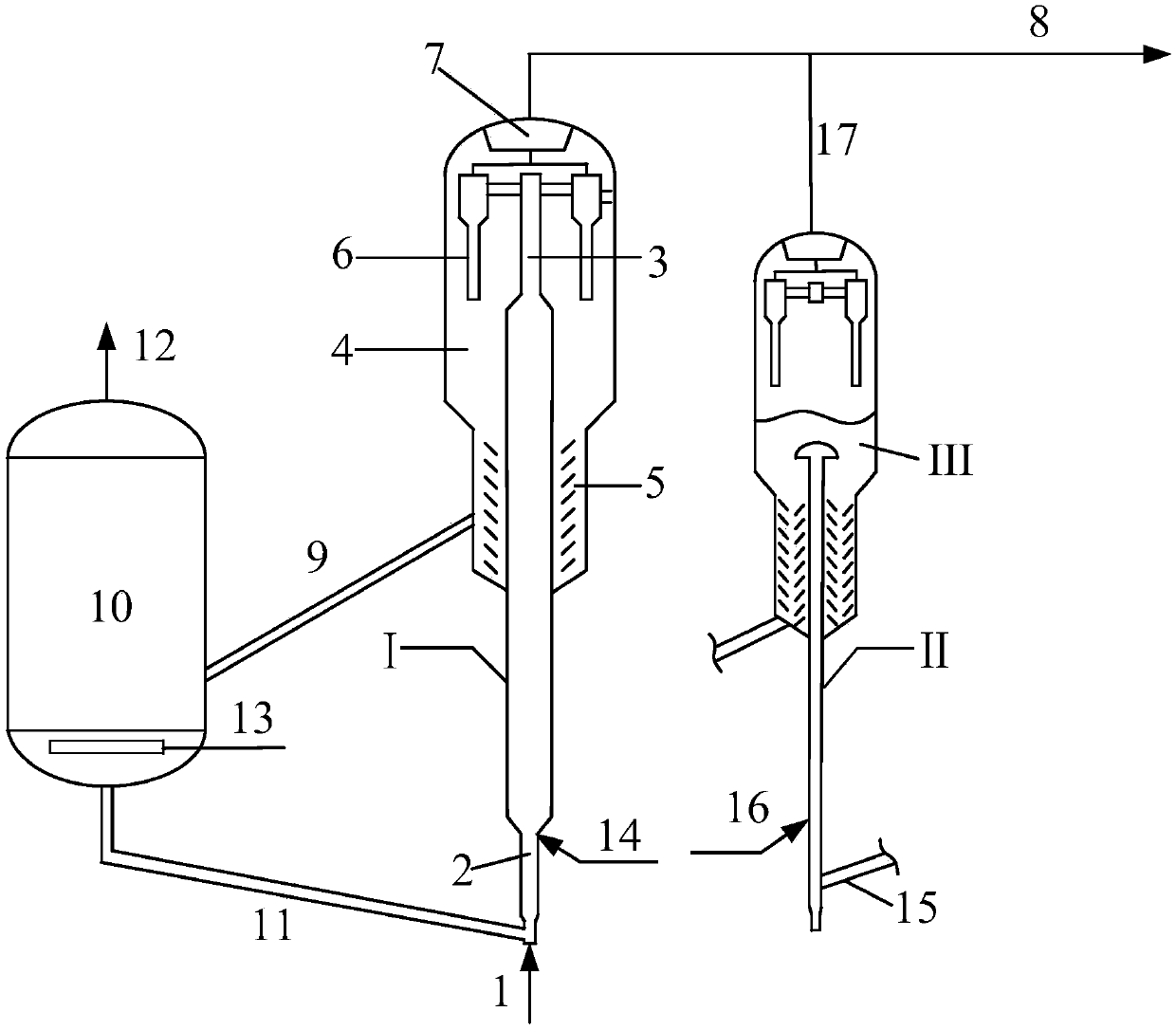

[0095] according to figure 1 The test process is carried out, the low-quality raw material oil is hydrogenated residual oil, and the light raw material oil is catalytically cracked gasoline. The test was carried out on a medium-sized device, and the reactor was divided into the first reactor (fast fluidized bed) and the second reactor (dense phase fluidized bed in series with dilute phase conveying bed), and the preheated inferior raw material oil entered the fast fluidized bed The lower part is in contact with the regenerated catalyst and undergoes catalytic cracking reaction. By adjusting the gas linear velocity and setting an umbrella-shaped gas distributor at the feed position, the catalyst in the fast fluidized bed is controlled to be in a full dense phase distribution, and the axial solid fraction in the fast fluidized bed is The ε distribution is in the range of 0.1-0.2 from bottom to top. The light feedstock oil enters the lower part of the dilute-phase conveying bed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com