Apparatus and method for monitoring metal corrosion under organic coating

A metal corrosion and organic coating technology, applied in the field of devices for monitoring metal corrosion under organic coatings, can solve the problems of environmental pollution, social impact, shedding, time-consuming and cost-consuming, etc., and achieves simple and flexible operation, small passivation current, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

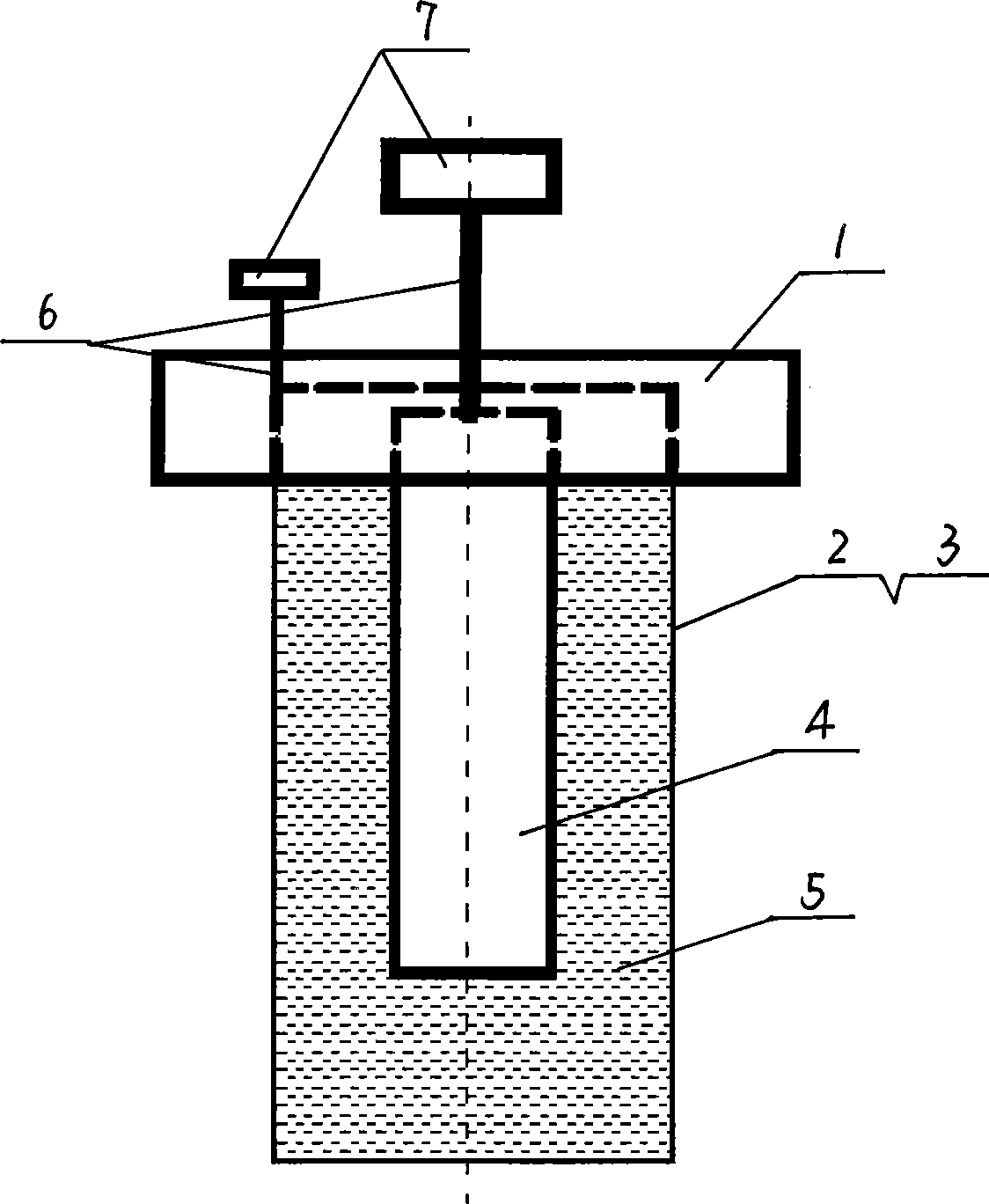

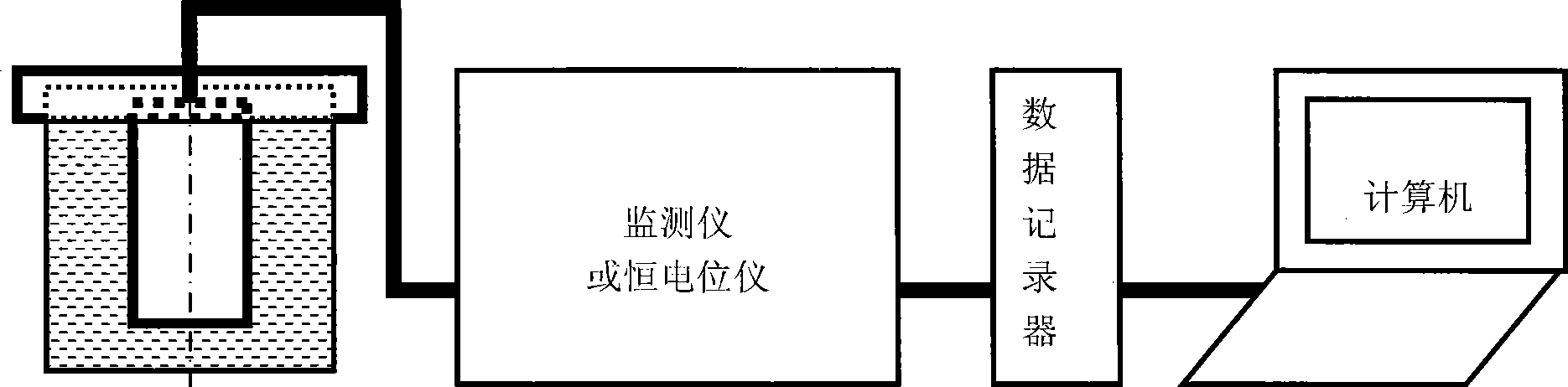

[0027] Such as figure 1 As shown, the present invention includes an electrolytic cell cap 1, a bucket 2 identical to the metal material to be monitored, a nickel rod 4 and a connector 7. The present embodiment adopts a 35CrMo steel thin-walled cylinder with a wall thickness of 0.3-0.5mm. The inner wall of the drum 2 is plated with a nickel layer, and the outer surface is provided with a coating 3. The coating of this embodiment is a commercially available product, and the EPONICS SHB (ultra-thick film epoxy coating Co., Ltd. Resin coating), electrolyte solution 5 is housed in drum 2. The lower end of the electrolytic cell cap 1 is provided with a groove, and one end of the nickel rod 4 is inserted into the electrolyte 5 in the drum 2, but not in contact with the inner wall of the drum 2, and the other end is connected with the electrolytic cell cap 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com