Metal tube structure-based fiber grating corrosion sensor and monitoring method thereof

A technology of corrosion sensor and optical fiber grating, which is applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc. It can solve the requirements of limiting the thickness and uniformity of the cylindrical coating, high requirements for coating processing technology, measurement range and accuracy limitations and other issues, to achieve the effect of small size, good working reliability and simple packaging structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

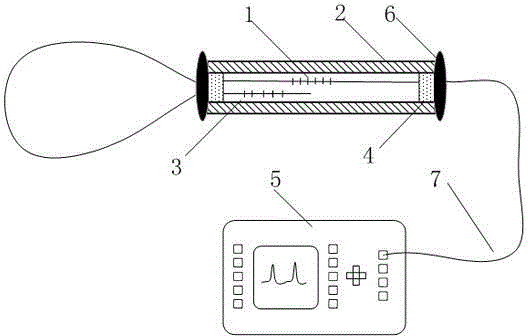

[0031] Below in conjunction with accompanying drawing, invention is further described:

[0032] The working principle of metal corrosion sensor based on fiber grating is as follows:

[0033] Will figure 1 The metal tube with the corrosion sensing fiber Bragg grating 1 and the temperature compensating fiber Bragg grating 3 placed in the center is placed in a corrosive environment. When the metal tube is corroded and the tube wall becomes thinner, the compression degree of the metal tube gradually increases, and this process causes the center wavelength of the fiber grating to gradually shift.

[0034] In order to facilitate the fixing of the fiber grating and avoid the influence of the epoxy resin on the grid area, the metal thin tube structure is adopted, and the length of the metal thin tube is designed to be 4 times the length of the used fiber grating grid area. Considering the corrosion monitoring range and sensitivity requirements comprehensively, the thickness of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com