Corrosion monitoring device and pipe string for corrosion monitoring of water injection well

A technology for corrosion monitoring and installation of rods, which is applied in the field of corrosion monitoring devices and pipe strings for corrosion monitoring of water injection wells. It can solve problems such as the inability to monitor the corrosion degree of downhole equipment in water injection wells, and achieve the effect of flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

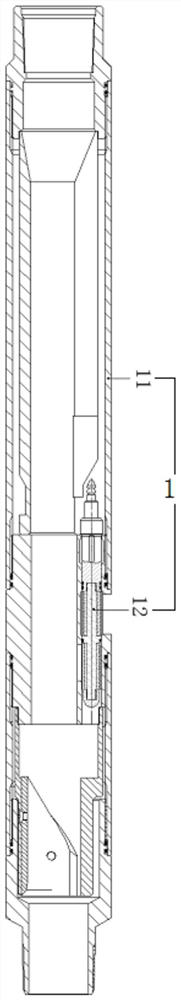

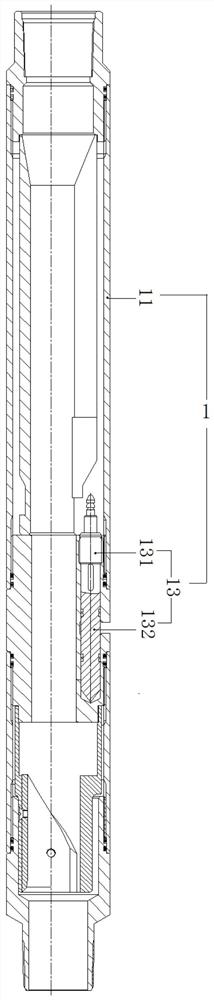

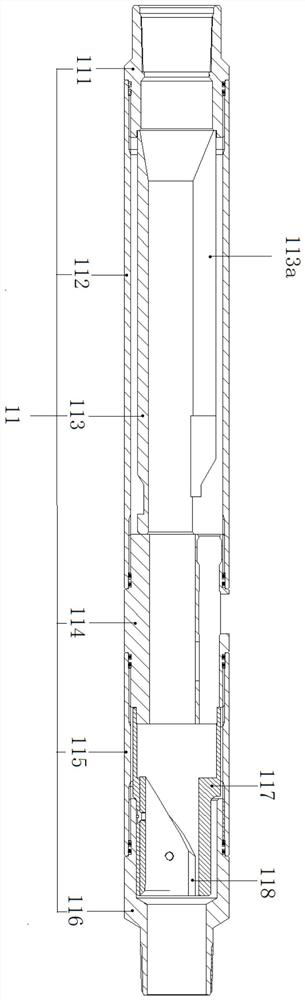

[0119] On the one hand, the embodiment of the present invention provides a corrosion monitoring device, such as the attached figure 1 , attached figure 2 As shown, the corrosion monitoring device 1 includes: a fixing piece 11 , a monitoring core 12 , and a blocking core 13 . as attached image 3 As shown, the fixing part 11 includes: an upper joint 111; an upper connecting cylinder 112 whose upper end is connected to the outer wall of the lower end of the upper joint 111; a fixed body 114 whose upper end is connected to the inner wall of the lower end of the upper connecting cylinder 112; the upper end is against the lower end of the upper joint 111 , the guide cylinder 113 whose lower end is against the upper end of the fixed body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com