Embedded steel bar corrosion rate monitoring sensor and method

A technology for monitoring the corrosion of sensors and steel bars, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of being easily affected by the external environment, the sensor cannot monitor the temperature, and the high cost of the sensor, so as to achieve simple structure, low cost, and overcome interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

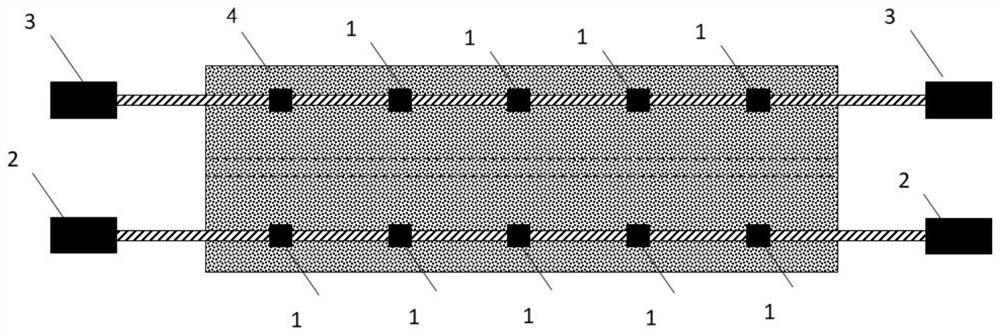

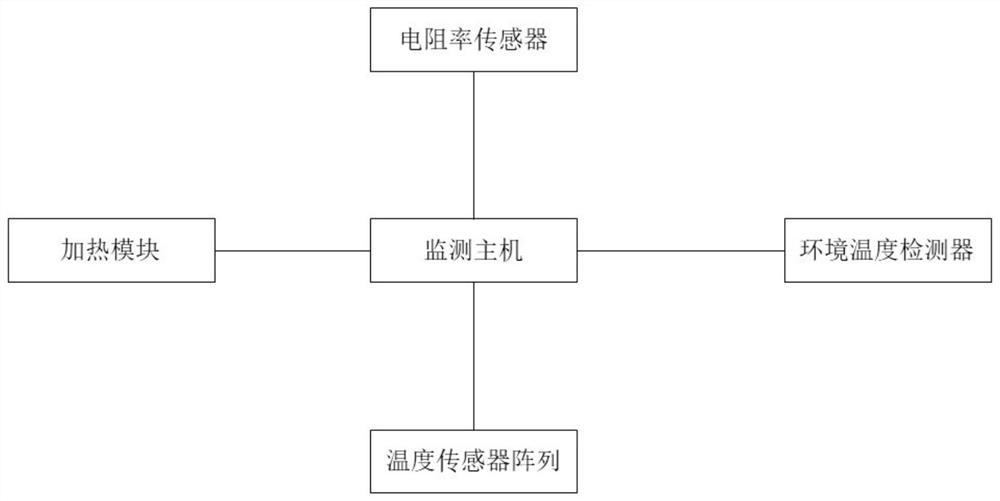

[0068] A pre-embedded steel bar corrosion rate monitoring sensor system includes a temperature sensor array, a resistivity sensor 2, a heating module 3, an ambient temperature detector and a monitoring host.

[0069] The steel bar is a plurality of steel bars located in the concrete in the concrete building, and the temperature sensor array is arranged on at least two steel bars; the temperature sensor 1 is attached to the surface of the steel bar, and the temperature sensor array includes a plurality of temperature sensors 1 arranged along the extension direction of the steel bar , and the distance between the temperature sensor 1 on the same steel bar is L, the distance L between a temperature sensor 1A and the temperature sensor 1B closest to itself on the same steel bar is equal to A, and the temperature sensor 1C closest to A on another steel bar the distance L;

[0070] The heating module 3 is arranged at both ends of a steel bar with a temperature sensor array, and the ...

Embodiment 2

[0079] A method using the monitoring sensor system in embodiment 1 to monitor steel bar corrosion rate, comprises the steps:

[0080] Step 1. System calibration;

[0081] Both the first steel bar and the second steel bar are provided with a temperature sensor array, and the two ends of the first steel bar are provided with a heating module 3, and the two ends of the second steel bar are provided with a resistivity sensor 2;

[0082] The monitoring host collects the temperature value of the ambient temperature detector, and the heating temperature of the heating module 3 is set to T+M according to the ambient temperature T; wherein M is the temperature difference between the ambient temperature and the heating temperature preset in the monitoring host;

[0083] Monitor the host and collect the temperature initial value T of the temperature sensor array at the same time 0ij and record, where T 0ij Indicates the initial temperature value of the jth temperature sensor 1 on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com