Gas well corrosion inhibitor and preparation method thereof

A corrosion inhibitor, oil and gas well technology, applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of thinning of pipe wall corrosion, increased difficulty of demulsification and dehydration of crude oil, poor compatibility of scale inhibitors, etc. Achieve the effect of sulfide stress corrosion inhibition, good sulfide stress corrosion, and overcoming local corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

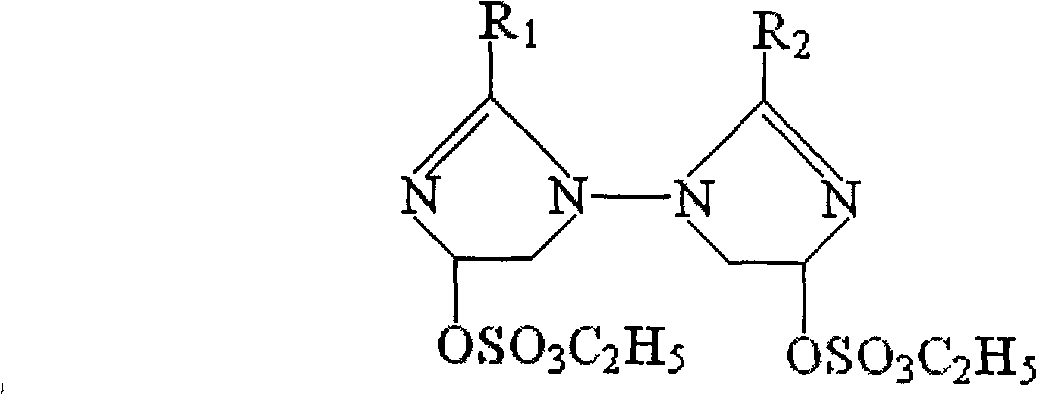

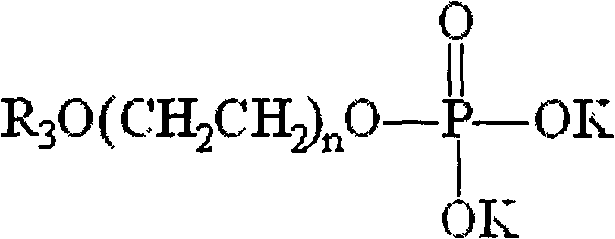

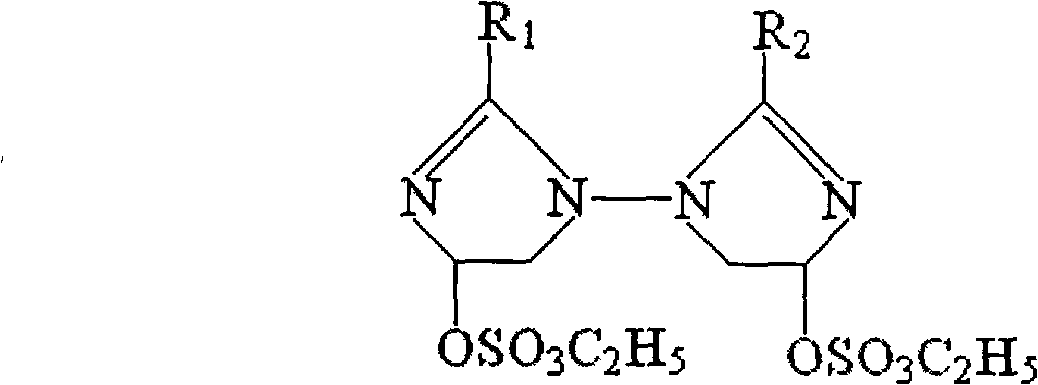

Method used

Image

Examples

Embodiment 1

[0041] 300kg gemini imidazoline surfactant; 150kg fatty alcohol polyoxyethylene ether phosphate; 100kg polyether demulsifier; 250kg fatty acid amide borate; 300kg solvent.

[0042] According to the formula ratio, add gemini imidazoline surfactant, fatty alcohol polyoxyethylene ether phosphate into a stainless steel reaction kettle, heat to about 75°C, stir for 30min-40min, then add fatty acid amide borate and polyether demulsifier, Stir for 20min to 30min, and finally add solvent and stir for 30min.

Embodiment 2

[0044] Gemini imidazoline surfactant 200kg; 100kg fatty alcohol polyoxyethylene ether phosphate; 50kg polyether demulsifier; 100kg fatty acid amide borate; 200kg solvent (alcohol or other polar solvent).

[0045] According to the formula ratio, add gemini imidazoline surfactant, fatty alcohol polyoxyethylene ether phosphate into a stainless steel reaction kettle, heat to about 75°C, stir for 30min-40min, then add fatty acid amide borate and polyether demulsifier, Stir for 20min to 30min, and finally add solvent and stir for 30min.

Embodiment 3

[0047] 250kg gemini imidazoline surfactant; 120kg fatty alcohol polyoxyethylene ether phosphate; 80kg polyether demulsifier; 180kg fatty acid amide borate; 250kg solvent.

[0048] According to the formula ratio, add gemini imidazoline surfactant, fatty alcohol polyoxyethylene ether phosphate into a stainless steel reaction kettle, heat to about 75°C, stir for 30min-40min, then add fatty acid amide borate and polyether demulsifier, Stir for 20min to 30min, and finally add solvent and stir for 30min.

[0049] The anticorrosion effect of the oil and gas well corrosion inhibitor prepared by the 3 examples is proved by experiments below, and the specific experimental conditions are:

[0050] Evaluation conditions

[0051] Salinity: according to the analysis results of produced water on site, use NaCl, NaHCO 3 、CaCL 2 , MgCL 2 .6H 2 O, Na 2 SO 4 Prepare mineralized water with a total salinity of 105g / L;

[0052] Evaluation pressure: total pressure 16.0Mpa, CO 2 Partial pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com