Color modified waterproof coating

A waterproof coating and modification technology, applied in the field of building materials, can solve problems such as difficult to stabilize quality, complex process flow, complex material composition, etc., and achieve the effect of reducing wire drawing, reducing cost and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

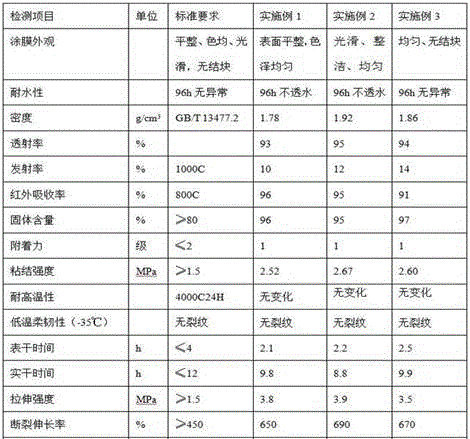

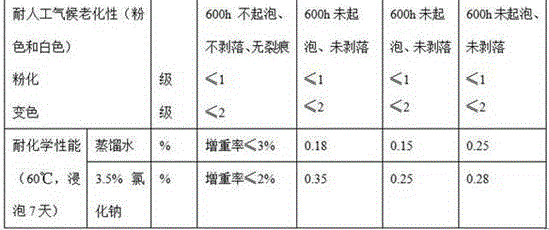

Examples

Embodiment 1

[0028] A kind of color modified waterproof paint, in kg, the raw material is

[0029] Film-forming agent: modified casein resin 80kg

[0030] Solvent: Silicone acrylic emulsion 20kg, carboxybutyl benzene 10kg

[0031] Film-forming aids: diethylene glycol monobutyl ether acetate 3kg, ethylene glycol butyl ether 2kg, dodecyl alcohol ester 5kg

[0032] Filler: glass fiber 4kg, organic diatomite 2kg, perlite powder 3kg and light calcium carbonate 3kg;

[0033] Pigment: Octahydroxyquinolinone 2kg, ferric oxide nano powder 1kg, rutile titanium dioxide 5kg, lithopone 1kg, iron oxide yellow 1kg

[0034] Auxiliaries are plasticizer, stabilizer, defoamer, catalyst and coupling agent, wherein plasticizer: linseed oil 3kg, oxidized castor oil 3kg; stabilizer: sodium carboxyethyl cellulose 1kg; defoamer: poly Oxypropylene polyoxyethylene glyceryl ether 0.5kg; catalyst: zinc caprylate 0.2kg, dibutyltin dilaurate: 0.5kg; coupling agent: silane coupling agent 2kg

[0035] The preparation ...

Embodiment 2

[0040] A kind of color modified waterproof paint, in kg, the raw material is

[0041] Film-forming agent: modified casein resin 90kg

[0042] Solvent: Silicone acrylic emulsion 30kg and carboxybutyl benzene 10kg

[0043] Filler: glass fiber 5kg, organic diatomite 2kg, perlite powder 3kg and light calcium carbonate 2kg

[0044] Pigment: octahydroxyquinolinone 2kg, ferric oxide nano powder 2kg, rutile titanium dioxide 4kg, lithopone 1kg, iron oxide yellow 2kg

[0045] Film-forming aids: ethylene glycol butyl ether 5kg, ethylene glycol monomethyl ether acetate 4kg

[0046] Auxiliaries are plasticizer, stabilizer, defoamer, catalyst and coupling agent, wherein plasticizer: linseed oil 3kg, oxidized castor oil 2kg; stabilizer: sodium carboxyethyl cellulose 2kg; defoamer: poly Dimethylsiloxane 0.6kg; catalyst: zinc octoate 0.6kg, dibutyltin dilaurate: 0.2kg; coupling agent: silane coupling agent 1kg, titanate coupling agent 1kg

[0047] The preparation method of this embodiment ...

Embodiment 3

[0052] A kind of color modified waterproof paint, in kg, the raw material is

[0053] Film-forming agent: modified casein resin 60kg

[0054] Solvent: Silicone acrylic emulsion 30kg and carboxybutyl benzene 10kg

[0055] Filler: glass fiber 4kg, organic diatomite 2kg, perlite powder 2kg and light calcium carbonate 4kg

[0056] Pigment: Octahydroxyquinolinone 3kg, ferric oxide nano powder 2kg, rutile titanium dioxide 3kg, lithopone 3kg, iron oxide yellow 1kg

[0057] Film-forming aids: diethylene glycol monobutyl ether acetate 2kg, ethylene glycol monobutyl ether acetate 3kg, propylene glycol methyl ether 6kg

[0058] Auxiliaries are plasticizers, stabilizers, defoamers, catalysts and coupling agents, of which plasticizer: dioctyl phthalate 7kg; stabilizer: polyvinyl alcohol 1.5kg; defoamer: polydimethyl base siloxane 0.6kg; catalyst: zinc octoate 0.6kg; dibutyltin dilaurate: 0.3kg; coupling agent: silane coupling agent 0.5kg, titanate coupling agent 1.5kg.

[0059] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com