Integrated black silica gel OCR for improving performance based on crosslinking density and preparation method ofintegrated black silica gel OCR

A technology for improving performance and cross-linking density, applied in the field of polymer nano-organosilicon materials, can solve the problems of decreased OCR mechanical ability of silica gel, affecting product quality, and difficulty in improving one-piece black

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

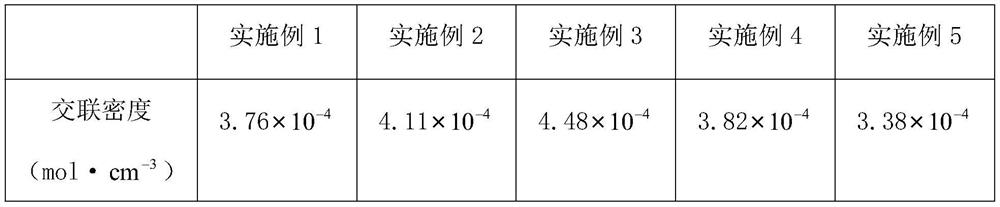

Embodiment 1

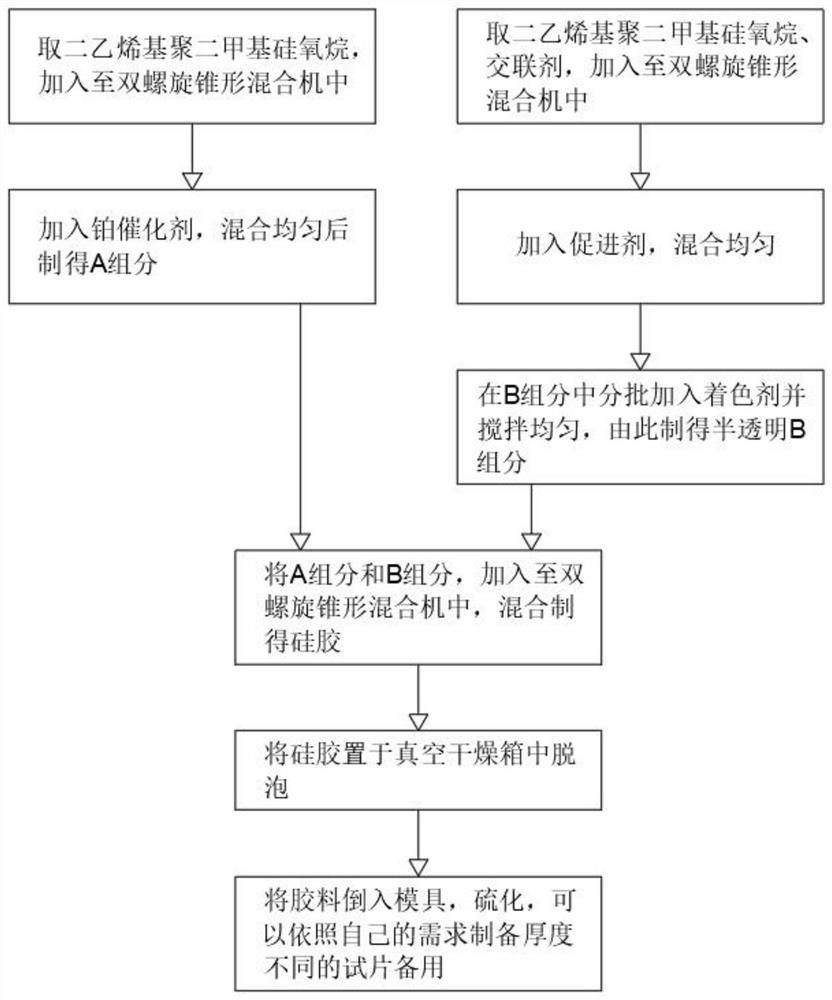

[0027] Embodiment 1 The one-piece black silica gel OCR and its preparation method based on cross-linking density to improve performance, including:

[0028] 1. Preparation of component A

[0029] Take 95% of divinyl polydimethylsiloxane, add it to a double-helix conical mixer, then add 5% platinum catalyst, and mix well to prepare component A;

[0030] 2. Preparation of component B

[0031] Take 80% of divinyl polydimethylsiloxane and 1% of cross-linking agent, add it to the double-helix conical mixer, then add 1% of accelerator, after mixing evenly, add coloring to component B in batches Add 0.01% of the agent, and stir evenly to prepare translucent B component;

[0032] 3. Preparation of addition-type thermally conductive silicone gel

[0033] Put component A and component B at a mass ratio of 1:1, add them to a double-helix conical mixer, and mix to obtain silica gel. Put the silica gel in a vacuum drying oven for 5-20 minutes to defoam, and pour the rubber into For the...

Embodiment 2

[0034] Embodiment 2 The one-piece black silica gel OCR and its preparation method based on cross-linking density to improve performance, including:

[0035] 1. Preparation of component A

[0036] Take 90% of divinyl polydimethylsiloxane, add it to a double-helix conical mixer, then add 4% platinum catalyst, and mix well to prepare component A;

[0037] 2. Preparation of component B

[0038] Take 82% of divinyl polydimethylsiloxane and 5% of cross-linking agent, add them to the double-helix conical mixer, then add accelerator 2, after mixing evenly, add the coloring agent to component B in batches 2%, and stir evenly to obtain translucent B component;

[0039] 3. Preparation of addition-type thermally conductive silicone gel

[0040] Put component A and component B at a mass ratio of 1:1, add them to a double-helix conical mixer, and mix to obtain silica gel. Put the silica gel in a vacuum drying oven for 5-20 minutes to defoam, and pour the rubber into For the mold, the te...

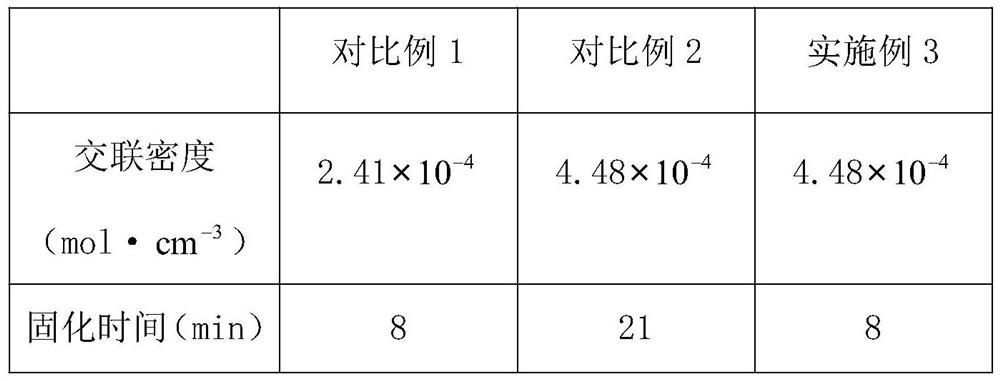

Embodiment 3

[0041] Embodiment 3 The one-piece black silica gel OCR and its preparation method based on cross-linking density to improve performance, including:

[0042] 1. Preparation of component A

[0043] Take 85% of divinyl polydimethylsiloxane, add it to a double-helix conical mixer, then add 3% platinum catalyst, and mix well to prepare component A;

[0044] 2. Preparation of component B

[0045] Take 85% of divinyl polydimethylsiloxane and 10% of cross-linking agent, add it to the double-helix conical mixer, then add 3% of accelerator, after mixing evenly, add coloring to component B in batches Add 3% of the agent, and stir evenly, so as to prepare the translucent B component;

[0046] 3. Preparation of addition-type thermally conductive silicone gel

[0047] Put component A and component B at a mass ratio of 1:1, add them to a double-helix conical mixer, and mix to obtain silica gel. Put the silica gel in a vacuum drying oven for 5-20 minutes to defoam, and pour the rubber into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com