Anticorrosion prestressed bars and its manufacture method

A technology of prestressing tendons and manufacturing methods, which is applied in manufacturing tools, ceramic molding machines, metal material coating processes, etc. The effect of good focus, low cost of raw materials and processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An anti-corrosion prestressed tendon-blackened high-strength steel wire or blackened steel strand. It is a blackened high-strength steel wire or blackened steel strand made by treating ordinary high-strength steel wire or smooth steel strand with a surface blackening process. The outer surface of the blackened high-strength steel wire or blackened steel strand is formed with a layer of black The film layer composition contains both Fe 3 o 4 , also contains FeS, CuS oxidation anti-corrosion layer.

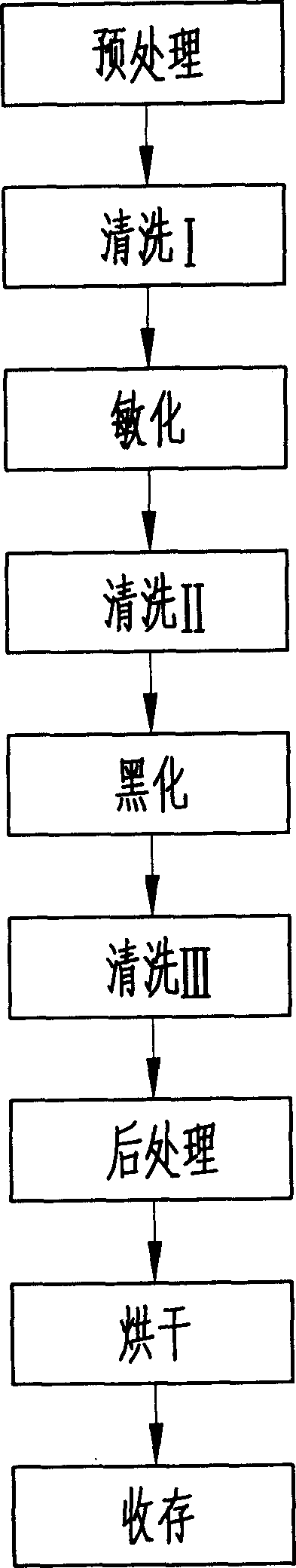

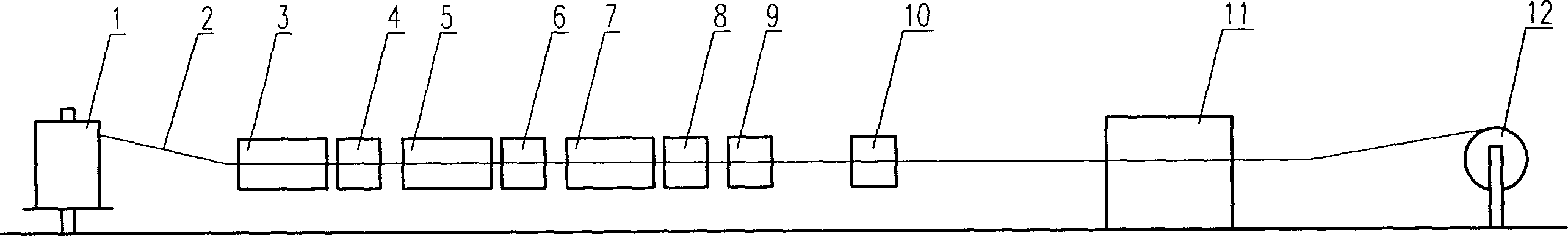

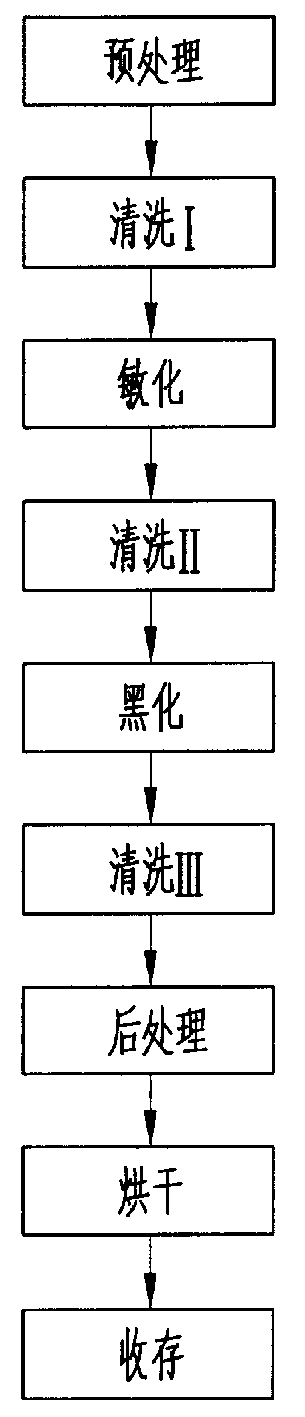

[0052] The method for carrying out high-strength steel wire or ordinary steel strand blackening process using the normal temperature iron and steel surface sensitization blackening agent composed of sensitizing liquid and normal temperature blackening liquid comprises the following process (see figure 1 , figure 2 ):

[0053] A, pretreatment process: degreasing and derusting pretreatment to the ordinary high-strength steel wire or smooth steel strand 2 unwound from the p...

Embodiment 2

[0074] An anti-corrosion prestressed tendon - blackened steel bar. It is a blackened steel bar made by treating ordinary steel bars with a surface blackening process. The outer surface of the blackened steel bar is formed with a layer of black film. The composition of the film layer contains Fe 3 o 4 , also contains FeS, CuS oxidation anti-corrosion layer. The surface blackening process treatment method and the normal temperature steel surface sensitization blackening agent adopted are the same as those in Example 1, the difference is that the steel bar has a larger diameter and cannot be wound into a coil, and can only be processed individually. Increase the size of the tanks or utensils used in pretreatment, cleaning I, sensitization, cleaning II, blackening, cleaning III, post-treatment, etc., and the drying process is carried out in an oven or a drying room. The black steel bars can be stacked neatly in the drying room.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com