A kind of method for preparing iron-nickel-phosphorus electroless coating

An electroless coating, iron-nickel-phosphorus technology, applied in the field of chemical deposition, can solve the problems of poor bonding between the coating and the substrate, low iron content in the coating, difficulty in obtaining a coating with a uniform thickness and composition, and achieve an increase in iron reduction speed, iron The effect of increasing the content and inhibiting the reduction rate of nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The 10×10×1.5mm silicon chip is put into the prepared chemical plating solution of the invention after degreasing, hydrofluoric acid and nitric acid mixed solution to remove the oxide film, and palladium chloride activation treatment. The plating solution is composed of KNaC 4 h 4 o 6 4H 2O 60-80g / L, disodium edetate 2-6g / L, diethylenetriaminepentaacetic acid 2-6g / L, NaH 2 PO 2 10-15g / L, boric acid 5g / L, sodium dodecylsulfonate 0.04g / L, NH 3 ·H 2 O 90-110mL / L; in solution, Fe 2+ Added in the form of ferrous ammonium sulfate, Ni 2+ Add in the form of nickel sulfate, the total molar concentration of ferrous ammonium sulfate and nickel sulfate is 0.08-0.10mol / L, Fe 2+ / Ni 2+ The molar ratio is 4 / 1.

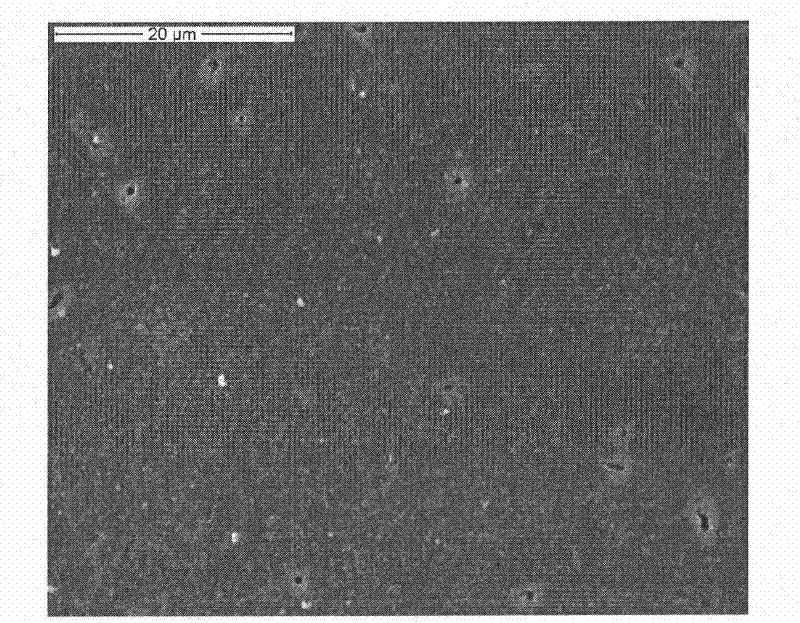

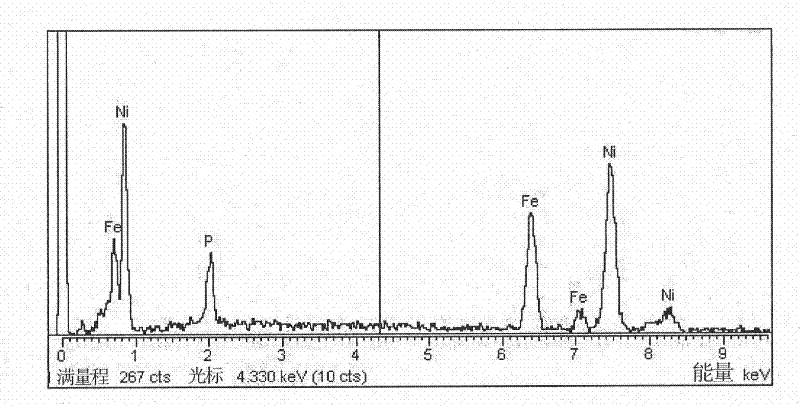

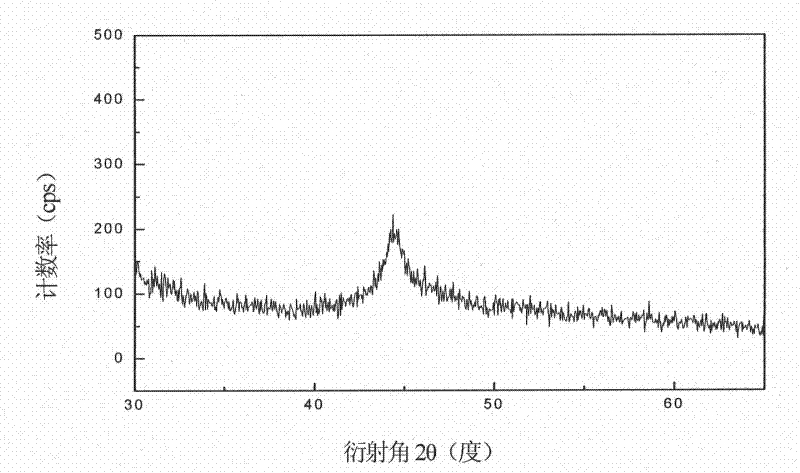

[0034] Cover the plating solution with xylene, put it in a water bath at 60°C, and react for 1 hour, the thickness of the coating is about 7-10 μm, and the surface appearance of the coating is as follows: figure 1 As shown, the coating chemical composition is as f...

Embodiment 2

[0036] The 10×10×1.5mm silicon chip is put into the prepared plating solution of the invention after degreasing, hydrofluoric acid nitric acid mixed solution to remove the oxide film, and palladium chloride activation treatment. The plating solution is composed of: KNaC 4 h 4 o 6 4H 2 O 60-80g / L, disodium edetate 2-4g / L, diethylenetriaminepentaacetic acid 2-4g / L, NaH 2 PO 2 10-15g / L, boric acid 5-8g / L, sodium dodecylsulfonate 0.04g / L, NH 3 ·H 2 O 90-110mL / L; in solution, Fe 2+ Added in the form of ferrous ammonium sulfate, Ni 2+ Add in the form of nickel sulfate, the total molar concentration of ferrous ammonium sulfate and nickel sulfate is 0.06-0.08mol / L, Fe 2+ / Ni 2+ The molar ratio is 4 / 1.

[0037] Cover the plating solution with xylene, put it in a water bath at 90° C., and react for 30 minutes. The thickness of the coating is about 6 μm, and the composition of the obtained coating is: 71.90Ni23.32Fe4.78P (atomic percent).

Embodiment 3

[0039] The 10×10×1.5mm silicon chip is put into the prepared plating solution of the invention after degreasing, hydrofluoric acid nitric acid mixed solution to remove the oxide film, and palladium chloride activation treatment. The plating solution is composed of: KNaC 4 h 4 o 6 4H 2 O 60-80g / L, glycamino acid 2-4g / L, iminoacetic acid 2-4g / L, NaH 2 PO 2 10-15g / L, boric acid 5-8g / L, sodium dodecylsulfonate 0.04g / L, NH 3 ·H 2 O 90-110mL / L; in solution, Fe 2+ Added in the form of ferrous ammonium sulfate, Ni 2+ Add in the form of nickel sulfate, the total molar concentration of ferrous ammonium sulfate and nickel sulfate is 0.10-0.12mol / L, Fe 2+ / Ni 2+ The molar ratio is 9 / 1.

[0040] Cover the plating solution with xylene, put it in a water bath at 70° C., and react for 30 minutes. The thickness of the coating is about 5 μm, and the composition of the obtained coating is: 68.44Ni13.95Fe17.61P (atomic percent).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com