Colorized heat-insulating waterproof coating

A waterproof coating and color technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of complex process flow, loss of thermal insulation decoration, difficult quality stability, etc., to reduce costs and reduce wire drawing. , the effect of increasing elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

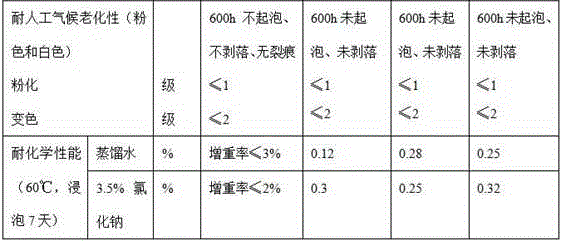

Examples

Embodiment 1

[0028] A kind of color and heat-insulating waterproof coating, in kg, the raw material is

[0029] Film-forming agent: modified casein resin 90kg

[0030] Film-forming aids: propylene glycol methyl ether 6kg, ethylene glycol butyl ether 4kg, ethylene glycol monomethyl ether acetate 3kg

[0031] Solvent: blended emulsion of silicone acrylic emulsion and cellulose acetate butyl solution 40kg

[0032] Pigments and fillers: 2kg of titanium dioxide, 3kg of basic lead sulfate, 1kg of cadmium yellow, 2kg of short glass fiber, 3kg of silica gel powder, 3kg of talcum powder and 5kg of heavy calcium;

[0033] UV absorber: 2-hydroxy-4-methoxybenzophenone 0.6kg

[0034] Auxiliaries are plasticizers, stabilizers, defoamers, catalysts and coupling agents, wherein plasticizers: butyl stearate 5kg, oxidized castor oil 3kg; stabilizers: sodium carboxyethyl cellulose 1.5kg; Foaming agent: 0.6 kg of polydimethylsiloxane; Catalyst: 0.4 kg of zinc octoate, dibutyltin dilaurate: 0.5 kg; Coupling...

Embodiment 2

[0040] A kind of color and heat-insulating waterproof coating, in kg, the raw material is

[0041] Film-forming agent: modified casein resin 100kg

[0042] Solvent: blended emulsion of silicon acrylic emulsion and cellulose acetate butyl solution 45kg

[0043] Pigments and fillers: 1kg of titanium dioxide, 5kg of basic lead sulfate, 0.5kg of cadmium yellow, 1kg of short glass fiber, 3kg of silica gel powder, 3kg of talcum powder and 6kg of heavy calcium;

[0044] UV absorber: 2-hydroxy-4-methoxybenzophenone 0.6kg

[0045] Film-forming aids: diethylene glycol monobutyl ether acetate 6kg, ethylene glycol monomethyl ether acetate 3kg

[0046] Auxiliaries are plasticizers, stabilizers, defoamers, catalysts and coupling agents, of which plasticizers: linseed oil 3kg, oxidized castor oil 2kg; stabilizers: polyvinyl alcohol 1kg; defoamers: polydimethyl 0.45 kg of siloxane; catalyst: 0.5 kg of zinc octoate, 0.3 kg of dibutyltin dilaurate; coupling agent: 1 kg of borate coupling age...

Embodiment 3

[0052] A kind of color and heat-insulating waterproof coating, in kg, the raw material is

[0053] Film-forming agent: modified casein resin 65kg

[0054] Solvent: blended emulsion of silicon acrylic emulsion and cellulose acetate butyl solution 35kg

[0055] Pigments and fillers: 1kg of titanium dioxide, 2kg of basic lead sulfate, 0.5kg of cadmium yellow, 1kg of short glass fiber, 3kg of silica gel powder, 3kg of talcum powder and 5kg of heavy calcium;

[0056] Film-forming aids: ethylene glycol monobutyl ether acetate 5kg, propylene glycol methyl ether 6kg

[0057] Auxiliaries are plasticizers, stabilizers, defoamers, catalysts and coupling agents, of which plasticizers: dioctyl phthalate 6kg; stabilizers: polyvinyl alcohol 1kg; defoamers: polydimethyl 0.6 kg of siloxane; Catalyst: 0.4 kg of zinc octoate; Dibutyltin dilaurate: 0.4 kg; Coupling agent: 0.5 kg of silane coupling agent, 1 kg of borate coupling agent.

[0058] The preparation method of this embodiment is:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com