Patents

Literature

33results about "Casein coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double in-situ method for preparing casein-based nano silicon dioxide composite leather finishing agent

InactiveCN102504131AImprove hygieneHigh fastnessCasein coatingsLeather surface finishingSilicic acidEthyl ester

The invention relates to a double in-situ method for preparing a casein-based nano silicon dioxide composite leather finishing agent. Casein has strong adhesive force, but forms a hard and fragile film with poor water resistance. The method comprises the following steps of: preparing a casein dissolving solution and an aqueous solution of caprolactam to obtain a caprolactam modified casein solution; adding 0.4 to 1.6 parts of tetraethoxysilane and 0.6 to 1.8 parts of silane coupling agent into the caprolactam modified casein solution; weighing 6.6 to 9.9 parts of mixed acrylic monomers, pouring the mixed acrylic monomers into the caprolactam modified casein solution, and stirring for emulsification; and dripping an aqueous solution of initiator into the caprolactam modified casein solution, and regulating the pH value to be 7.5 by using ammonia water to obtain the final product. The casein-based nano silicon dioxide composite leather finishing agent has the characteristics of strong adhesive force, high temperature resistance, high air permeability, high water resistance, excellent mechanical properties and the like, and is an environment-friendly material with good properties.

Owner:SHAANXI UNIV OF SCI & TECH

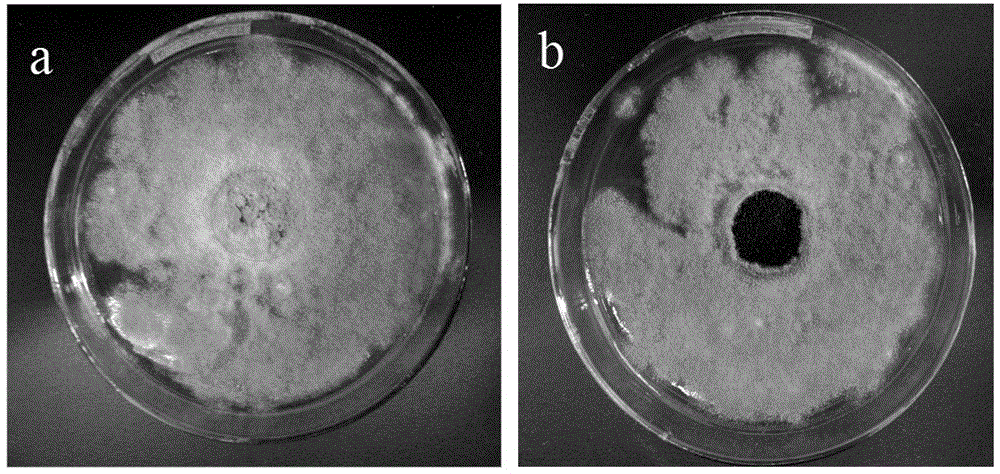

Antibacterial casein based nano ZnO composite leather finishing agent and preparation method thereof

ActiveCN104830231AImprove antibacterial propertiesCasein coatingsLeather surface finishingZno nanoparticlesAnti bacteria

The present invention relates to an antibacterial casein based nano ZnO composite leather finishing agent and a preparation method thereof. The study of introduction of nano-ZnO into a casein system for preparing leather finishing agent is rarely reported. The preparation method is as below: adding casein, lye and deionized water to a three-necked flask, and heating in a water bath to obtain a casein dissolved solution; dispersing the nano-ZnO in water to obtain a nano-ZnO dispersion liquid; compounding the nano-ZnO dispersion liquid and casein dissolved solution to obtain the antibacterial nano ZnO composite leather finishing agent. According to the invention, first casein is dissolved by lye in a suitable temperature environment to obtain a casein dissolved solution; and then the nano-ZnO dispersion liquid and casein dissolved solution are compounded through a certain method to introduce ZnO nanoparticles into the casein system, so as to obtain the inorganic / casein leather finishing agent with excellent performance and excellent antibacterial properties.

Owner:广州麦吉高分子新材料科技有限公司

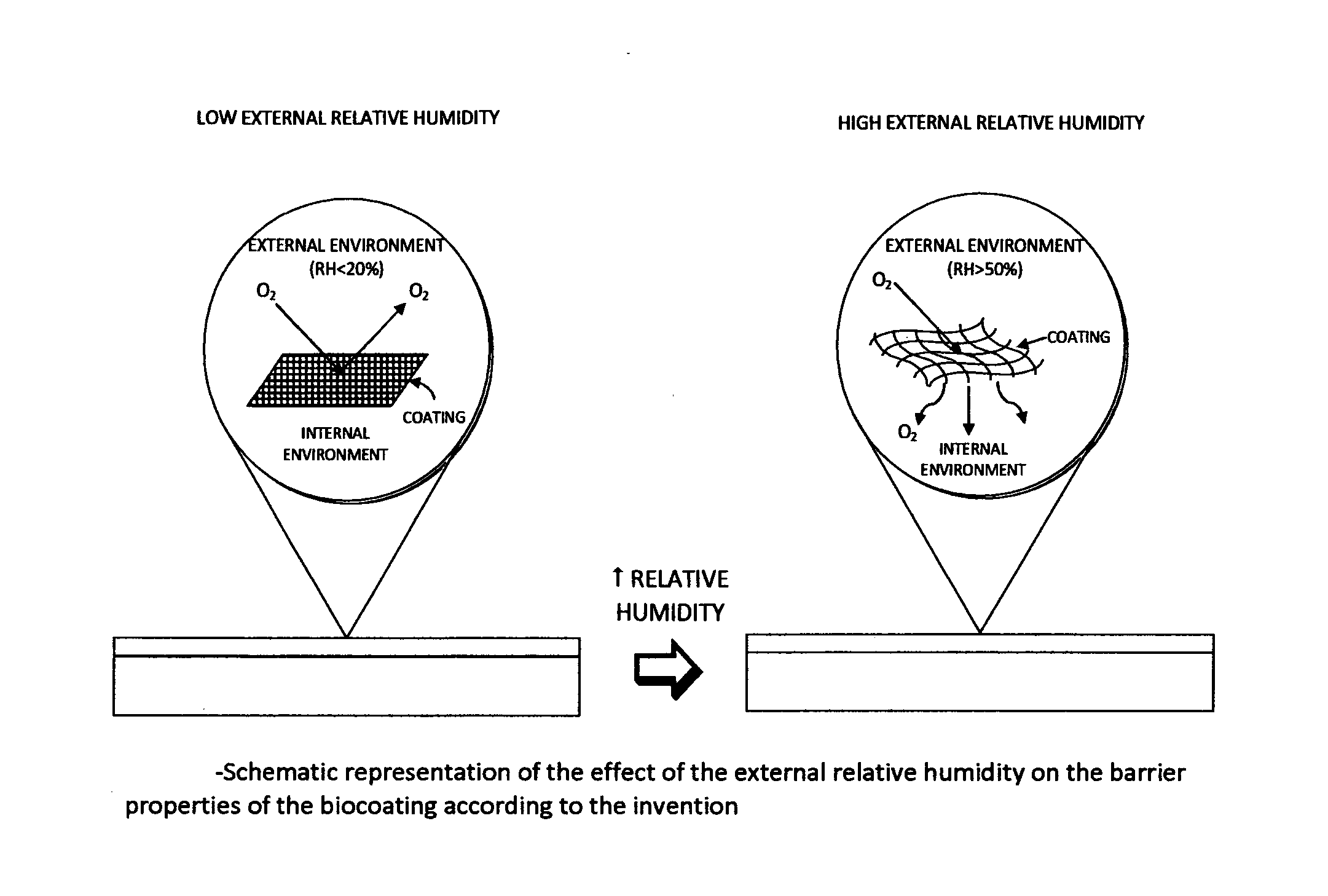

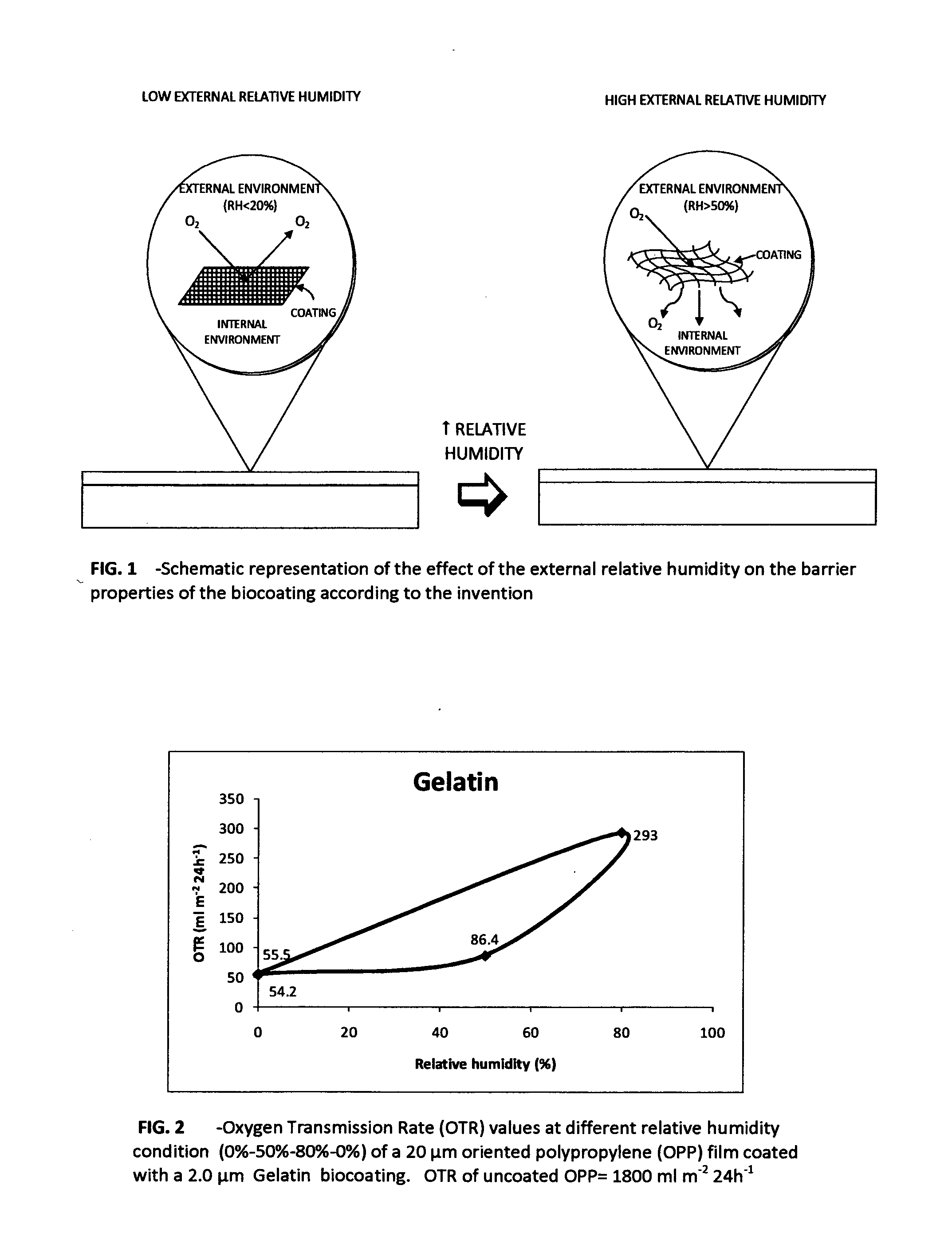

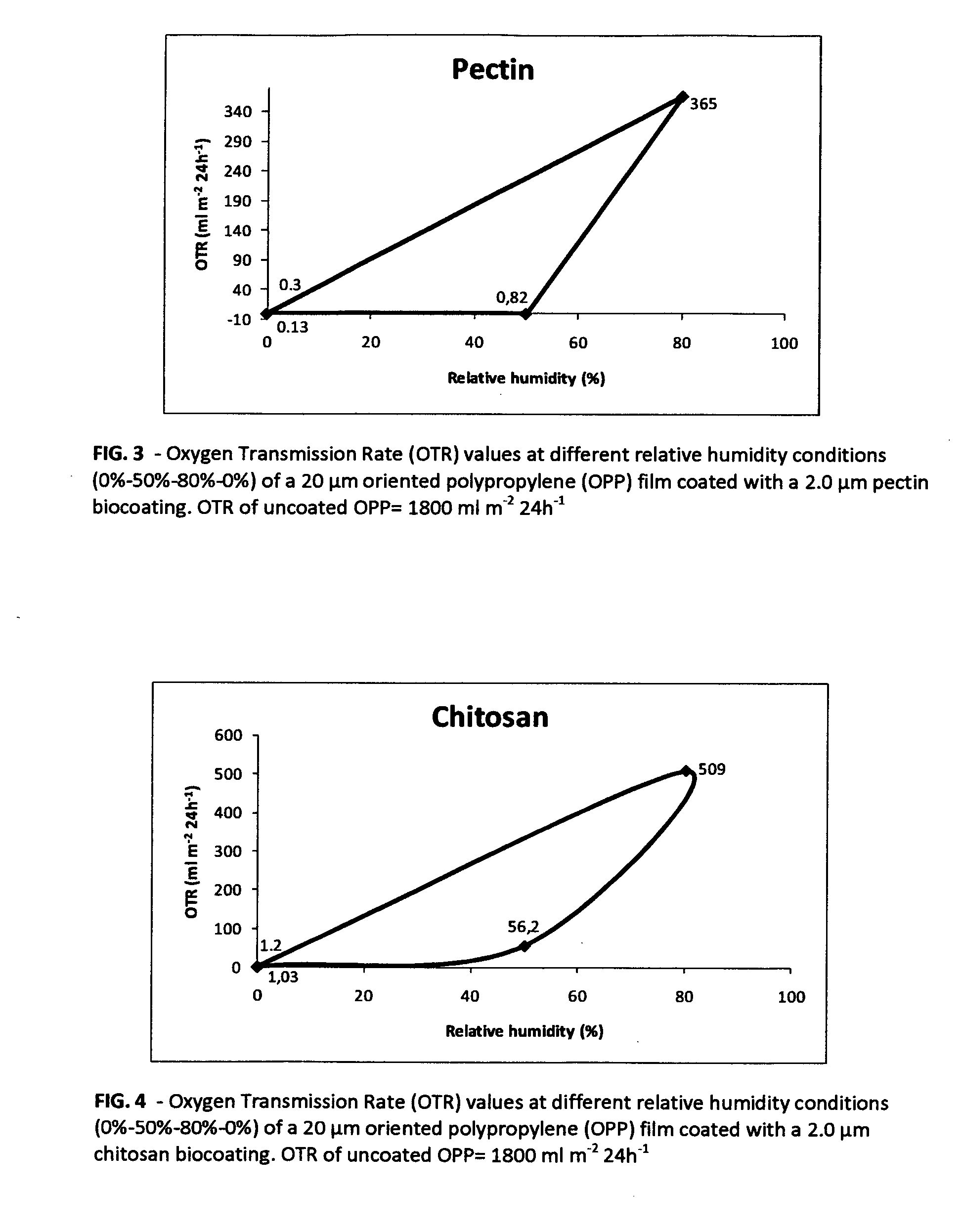

Coatings from natural macromolecules, with gas barrier properties tailored in situ, and related preparation method

InactiveUS20110283918A1Strong adhesionCosmetic preparationsPeptide/protein ingredientsBarrier effectGelatin

The invention concerns lake compositions based on natural macromolecules (gelatin, chitosan, pectine etc.) with possible additions of vinyl polymers, metal-alcoxides etc., characterized by a barrier effect modulated in situ, in particular as a function of the relative humidity in the exterior ambient.

Owner:MIRANTE

Coating compositions

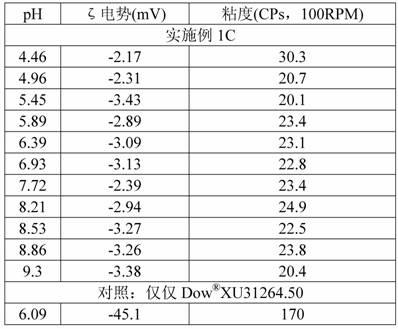

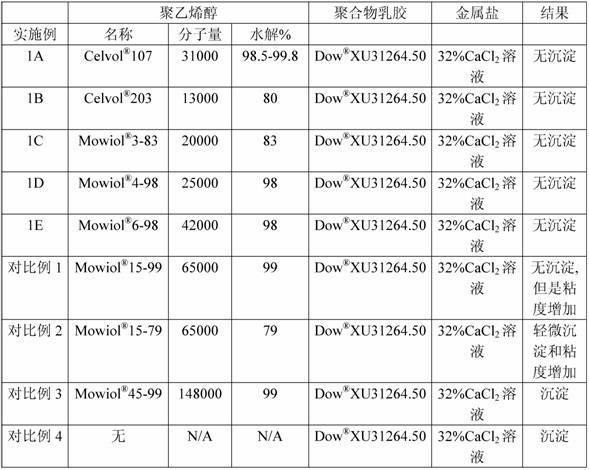

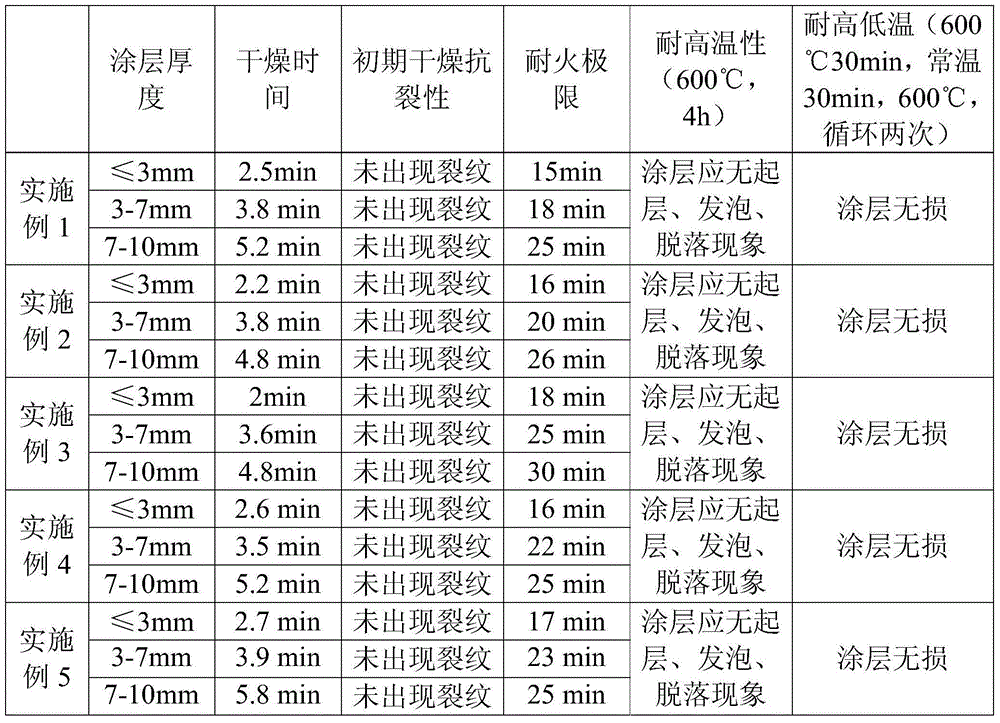

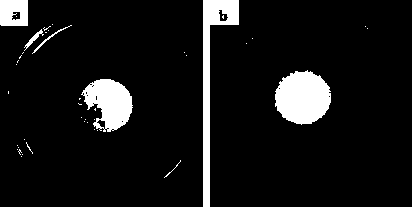

ActiveCN102471627AShorten drying timeStarch dervative coatingsCoatings with pigmentsPVA - Polyvinyl alcoholWeight range

A coating composition includes pigments or a mixture of pigments, a surface active substance and a metal containing polymeric complex. The metal containing polymeric complex contains a metallic salt, a polymeric latex and polyvinyl alcohol (PVA), wherein the polyvinyl alcohol has a molecular weight ranging from about 10,000 to about 65,000.

Owner:HEWLETT PACKARD DEV CO LP

Fireproof oil paint

InactiveCN104927522AImprove heat resistanceImprove flame retardant performanceFireproof paintsCasein coatingsCrack resistanceAcrylic resin

The invention relates to the technical field of oil paint, in particular to fireproof oil paint. The fireproof oil paint is composed of, by mass, 6-12 parts of stearic acid, 6-12 parts of sorbic stearic acid, 3-6 parts of carbomer, 1.8-4.8 parts of mica powder, 5-10 parts of acrylic resin modified casein film formers, 0.2-0.8 part of flame retardant and 8-16 parts of zeolite powder. By the adoption of the technical scheme, the fireproof oil paint has the advantages that the modified mica powder which is modified by a silane coupling agent KH-570, the zeolite powder, the modified amino resin and the chloride-vinyl acetate copolymeter are added, so that the heat resistance of the oil paint is improved, and the flame retardant effect is good. Moreover, the fireproof oil paint has the good corrosion resistance and crack resistance.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

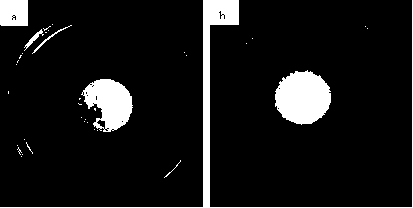

Anti-static anti-bacterial chitosan-casein composite leather finishing agent and preparation method thereof

ActiveCN108342111AImprove stabilitySimple methodAntifouling/underwater paintsCasein coatingsNatural productAnti bacterial

The invention provides a preparation method of an anti-static anti-bacterial chitosan-casein composite leather finishing agent. The preparation method of the anti-static anti-bacterial chitosan-caseincomposite leather finishing agent includes the following steps of 1, dissolving chitosan; 2, dissolving casein; 3, preparing the anti-static anti-bacterial chitosan-casein composite leather finishingagent. Raw materials adopted in the preparation method are biodegradable; a composite technology is adopted, so that the preparation method is simple, the stability of products is good, the preparedanti-static anti-bacterial chitosan-casein composite leather finishing agent is a natural-product-based leather finishing agent with two functions of preventing static and bacteria.

Owner:SHAANXI UNIV OF SCI & TECH

Modified casein emulsion and application thereof

The invention relates to the field of coating and ink, and in particular to a modified casein emulsion and application thereof. The modified casein emulsion is prepared from the following components:3 to 7 parts by weight of casein, 0.4 to 1.0 part by weight of thickening agent, 0.1 to 0.7 part by weight of gelator, 0.1 to 0.5 part by weight of surfactant, 0.1 to 0.7 part by weight of defoaming agent, 0.1 to 0.7 part by weight of preservative, 0.1 to 0.7 part by weight of cosolvent and 80 to 95 parts by weight of distilled water.

Owner:上海欧畅新材料科技有限公司

Conversion coating for magnesium, beryllium and their alloys and articles thereof

InactiveUS20090178586A1Easily accept applied coatingMore corrosion resistant surfaceAnodisationCasein coatingsChromate conversion coatingToxic proteins

I provide a non-toxic protein and protein compound conversion coated metal article, a painted or plated non-toxic protein and protein compound conversion coated metal article, the aqueous coating solution to provide the in-situ conversion protective coating, and a process of preparing the article. The article is a metal selected from the group consisting of magnesium, magnesium alloy, beryllium and beryllium alloy. The solution has a pH of 3.0 to 12.0 and preferably 4.0 to 10.0 and a protein and protein compound concentration of 0.1 to 10% by weight and the protein and protein compound have a molecular mass of 16,700 to 1,000,000.

Owner:SAN FU CHEM CO LTD

Oxygen barrier film, food packaging material comprising same, and method for producing oxygen barrier film

PendingUS20220153938A1Improve adhesionEasy to manufactureWrappersNon-macromolecular adhesive additivesPolymer scienceFood packaging

Disclosed are an oxygen barrier film, a food wrapper including the same, and a method of preparing the oxygen barrier film. The oxygen barrier film may include: a base layer; and an organic / inorganic hybrid layer located on the base layer and including a natural hydrogel and a silane coupling agent.

Owner:EVERCHEMTECH

Novel thermal-insulation waterproof coating used for solar energy devices

InactiveCN108342115AStrong adhesionImprove thermal conductivityFireproof paintsCasein coatingsHigh absorptionAcrylic resin

The invention relates to a novel thermal-insulation waterproof coating used for solar energy devices. The coating is prepared from the following components in parts by weight: 44-87 parts of a film forming agent, 28-32 parts of acrylic resin, 1-3 parts of polyvinylpyrrolidone, 1.0-2.4 parts of carbon black, 1.1-1.8 parts of chrome oxide green, 8-10 parts of methyl isobutyl ketone, 13-25 parts of afilm forming auxiliary agent, 4-9 parts of enamel black, 44-63 parts of a light absorbing agent, 1-3 parts of chlorinated paraffin, 1-2 parts of carbon black, 8-10 parts of precipitated barium sulfate, 23-47 parts of a solvent, 4-8 parts of a manganese ferrite black pigment, 6-23 parts of an auxiliary agent, 0.2-0.4 part of a silane coupling agent, and 1-2 parts of sulfonated graphene. The coating provided by the invention has the advantages that a coating layer prepared from the coating has a high absorption rate, high thermal conductivity, low radiance and high stability, and a conversion rate of solar energy by an endothermic coating is effectively improved; and the coating has good weather resistance and water resistance, and is a solar energy endothermic coating especially suitable for a solar energy heat absorber.

Owner:JIANGSU SHUANGNENG SOLAR ENERGY

Solar selective heat-absorbing coating

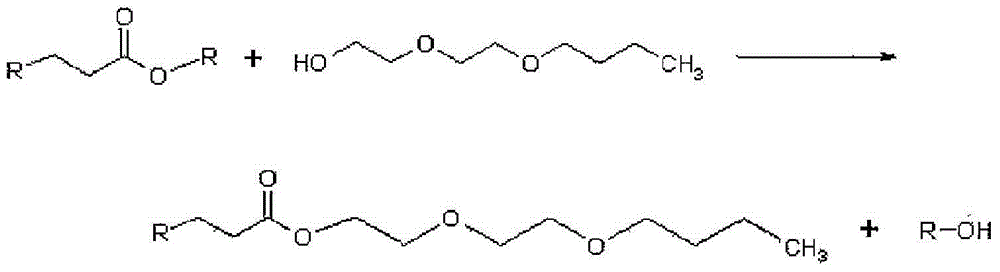

InactiveCN105670506AReduce hydrophilicityImprove waterproof performanceCasein coatingsRadiation-absorbing paintsUltraviolet lightsSolvent

The invention discloses a solar selective heat-absorbing coating. A light absorbing agent, a film forming agent, a solvent and an aid are evenly dispersed with a ball-milling method, a coalescing agent is added, and the solar selective heat-absorbing coating can be obtained after mixing. The coating is prepared from raw materials in parts by weight as follows: 50-100 parts of the film forming agent, 10-30 parts of the coalescing agent, 35-55 parts of the light absorbing agent, 20-50 parts of the solvent and 10-30 parts of the aid; the coalescing agent is propylene glycol butyl ether, propylene glycol monomethyl ether acetate and the like; a preparation method of the film forming agent comprises steps as follows: casein and gelatin are mixed in the weight ratio being (5-10):(2-3), water is added, the mixture is soaked at 15-22 DEG C and then transferred to a normal-temperature environment, a mixture of methyl acrylate and hexamethyldisiloxane in the weight ratio being (1-2):)(1-3) is added, the mixture is stirred and then irradiated under ultraviolet light for 10-15 min, and then modified casein-gelatin is obtained. The film forming agent is modified to be used as an important raw material for preparing the coating, the prepared coating has good weather resistance and waterproofness outdoors, the preparation process is simple and easy to understand, and the heat absorption efficiency of the heat-absorbing coating is guaranteed.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

Sealing composition

A sealant composition for the sealing of a punctured tire including a liquid carrier, one or more viscosity and suspending agents, one or more fillers and sealants, and one or more polyacrylates.

Owner:TRYDEL RES PTY LTD

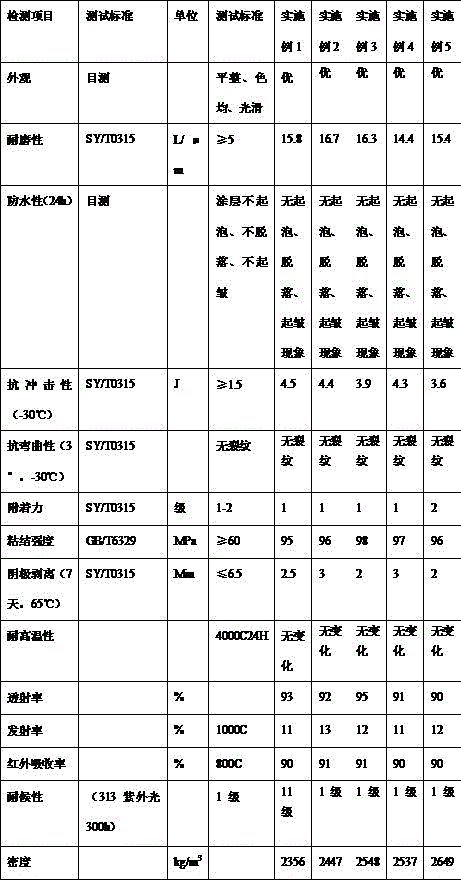

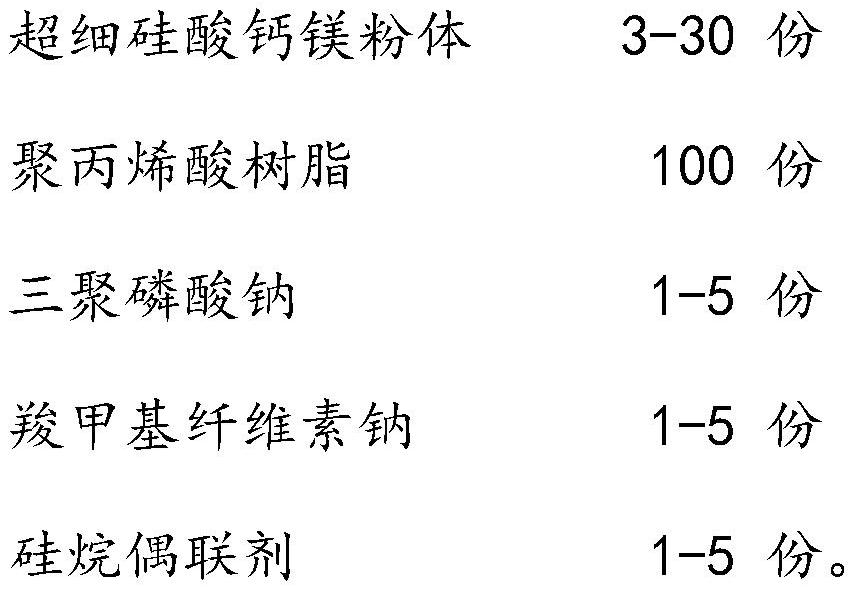

Calcium magnesium silicate/polyacrylic resin composite material as well as preparation method and application thereof

PendingCN112920656AGood dispersionImprove performanceCasein coatingsPolyurea/polyurethane coatingsCalcium silicateCellulose

The invention discloses a calcium magnesium silicate / polyacrylic resin composite material as well as a preparation method and application thereof. The calcium magnesium silicate / polyacrylic resin composite material comprises 3-30 parts of superfine calcium magnesium silicate powder, 100 parts of polyacrylic resin, 1-5 parts of sodium tripolyphosphate, 1-5 parts of sodium carboxymethyl cellulose and 1-5 parts of a silane coupling agent. The water absorption rate of the calcium magnesium silicate / polyacrylic resin composite material can be reduced from more than or equal to 100% to 40-70% compared with that of acrylic resin, meanwhile, the hand feeling of a coating is improved, and finished leather is endowed with smooth hand feeling.

Owner:XINGYE LEATHER TECH CO LTD

A kind of modified casein emulsion and its application

The invention relates to the field of coating and ink, and in particular to a modified casein emulsion and application thereof. The modified casein emulsion is prepared from the following components:3 to 7 parts by weight of casein, 0.4 to 1.0 part by weight of thickening agent, 0.1 to 0.7 part by weight of gelator, 0.1 to 0.5 part by weight of surfactant, 0.1 to 0.7 part by weight of defoaming agent, 0.1 to 0.7 part by weight of preservative, 0.1 to 0.7 part by weight of cosolvent and 80 to 95 parts by weight of distilled water.

Owner:上海欧畅新材料科技有限公司

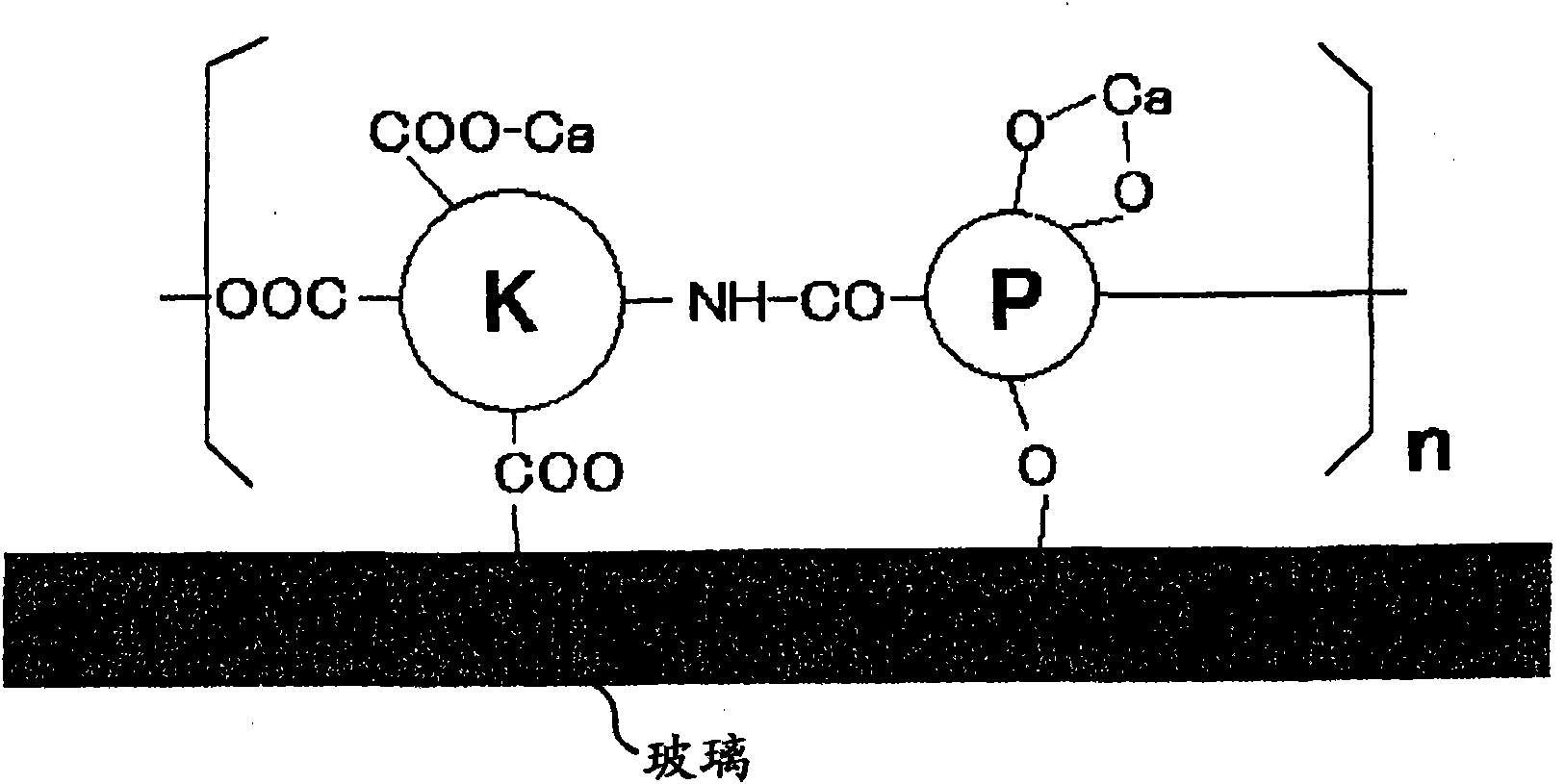

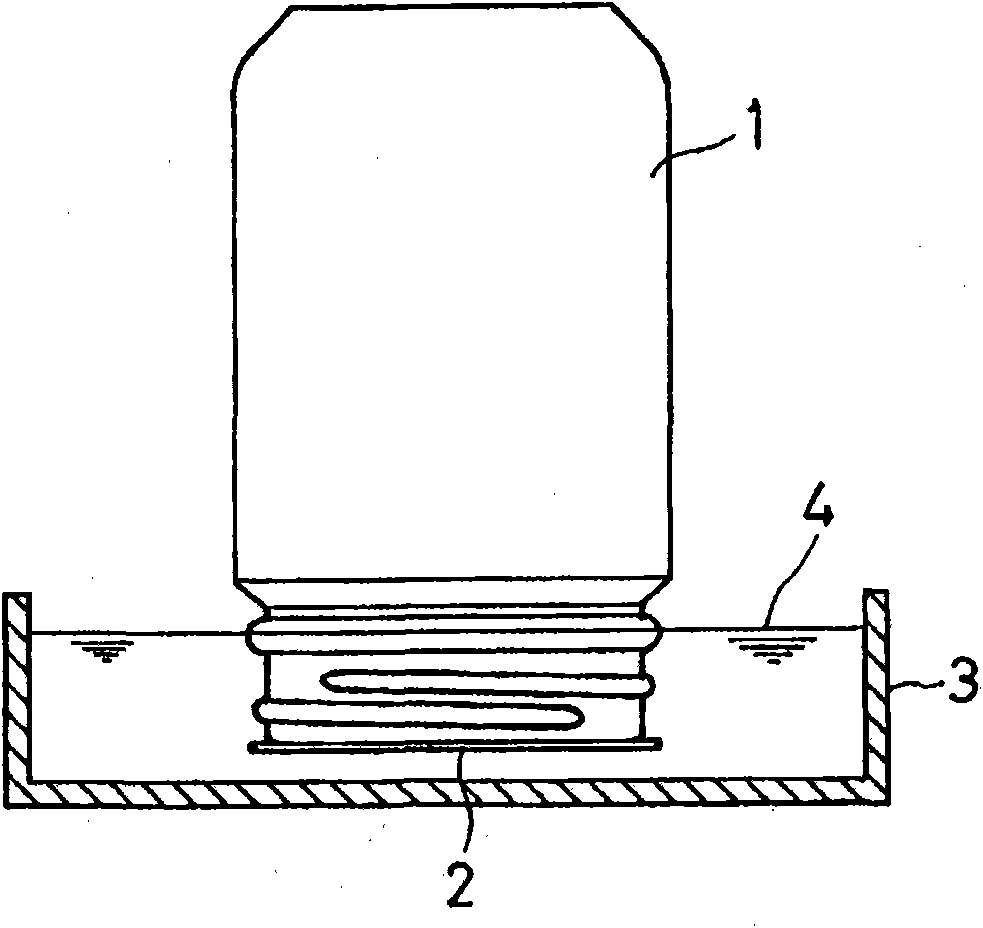

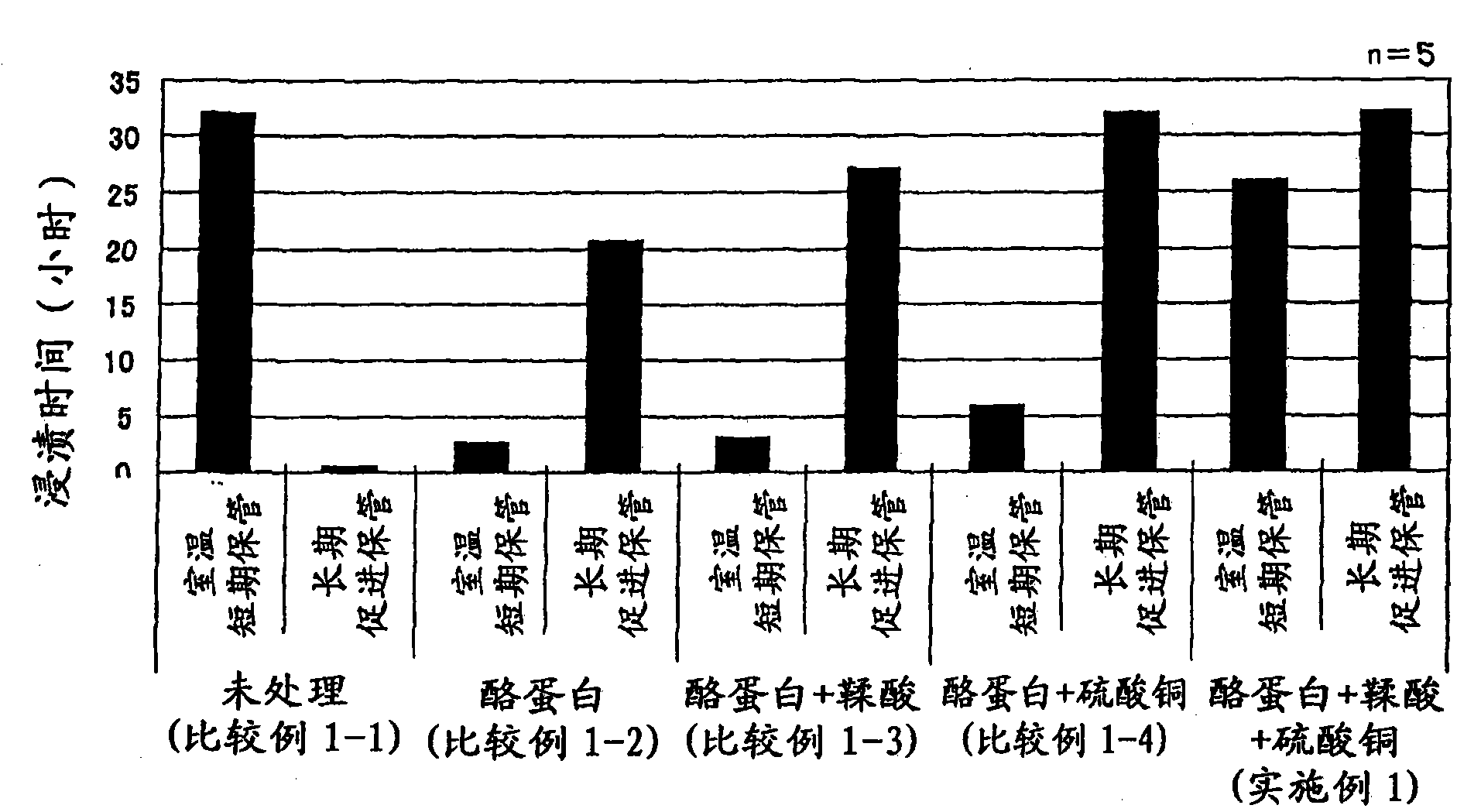

Process for sealing glass containers, glass containers and coating material

InactiveCN101801806ADecorative coversClosure decorative/protective coversCalcium hydroxideAqueous solution

The invention realizes water-resistant sealing of a glass container (1) independent of the weathering of glass. Water-resistant sealing of a glass container (1) independent of the weathering of glass can be attained by subjecting the top surface of the mouth of a glass container (1) to hot end coating, applying a coating material consisting of an aqueous solution which contains casein, a polyphenol and at least one member selected from among copper sulfate, calcium hydroxide and iron chloride to the resulting top surface, and then bonding a seal (2) coated with a thermoplastic resin to the top surface.

Owner:TOYO GLASS CO LTD

Volatilization-preventing material for wholesale business transportation vehicle, and preparation method thereof

The invention discloses a volatilization-preventing material for a wholesale business transportation vehicle, and a preparation method thereof. The volatilization-preventing material for the wholesale business transportation vehicle comprises the following raw materials in parts by weight: 30 to 60 parts of calcite, 10 to 15 parts of casein plastic, 10 to 20 parts of an ethylene-propylene-diene terpolymer, 3 to 6 parts of zoisite, 3 to 5 parts of graphene, 3 to 5 parts of a dispersing agent, 3 to 8 parts of a stabilizing agent, 3 to 8 parts of a defoaming agent, 2 to 4 parts of a coupling agent, 2 to 4 parts of a curing agent, 3 to 5 parts of a thickening agent and 30 to 50 parts of water. The volatilization-preventing material for the wholesale business transportation vehicle is smeared at the outlet position of a transportation container, can be solidified quickly, achieves an effective blocking effect on most of organic compounds, does not need dissolved corrosion, has a good blocking effect and can exert the effect for a long time.

Owner:天津诚信科技发展股份有限公司

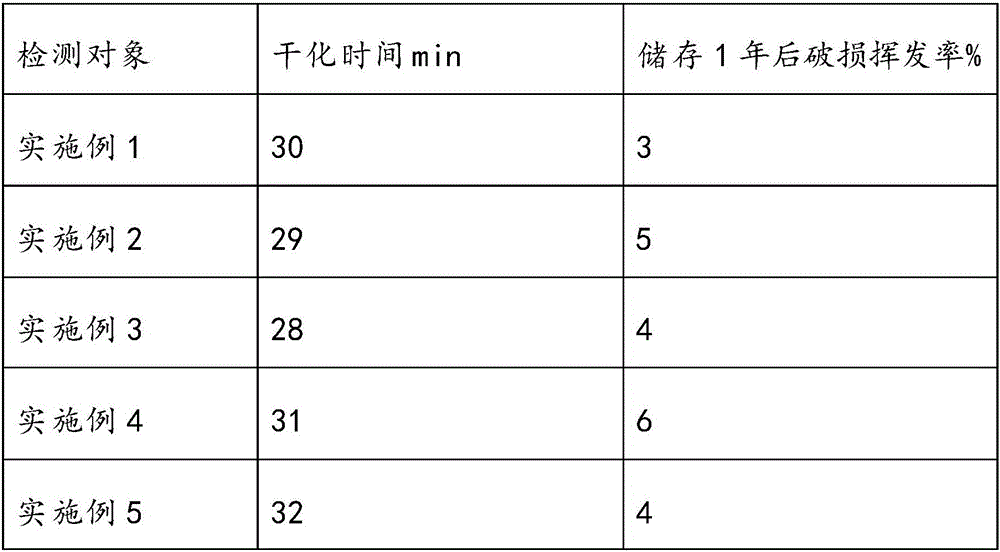

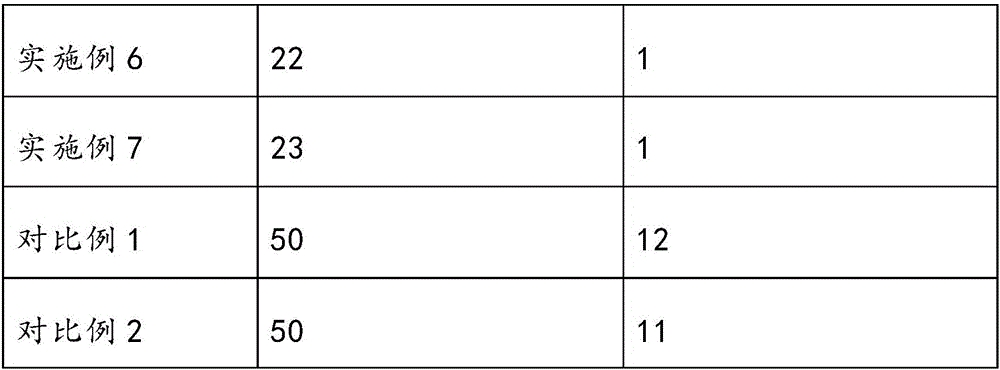

Moisturizing dust suppressant for road dust and preparation method thereof

ActiveCN111995985BPrevent secondary liftingGood moisturizing effectOther chemical processesCasein coatingsEmulsionActive agent

The invention belongs to the technical field of road dust control, and relates to a moisturizing dust suppressant for road dust and a preparation method thereof. The moisturizing dust suppressant for road dust of the present invention is prepared from the following raw materials in mass percent: 3.6% to 8% of a mixture of acetyl tributyl citrate, aqueous stearic acid emulsion and soluble starch, and 0.1% of a binder. ~10%, humectant 0.1~5%, surfactant 0.1~1%, balance is water. The road dust suppressant provided by the invention is sprayed on the road to form a layer of "soft film" with strong moisture retention, which can effectively condense the small particles on the ground surface into large particles, so as to effectively prevent the secondary raising of dust, thereby To achieve the effect of dust suppression.

Owner:中科恒华(山东)环保科技有限公司

Colorized heat-insulating waterproof coating

InactiveCN106497418AGood extensibilityImprove flex resistanceFireproof paintsAntifouling/underwater paintsAcetic acidEthyl ester

Colorized heat-insulating waterproof coating is disclosed. The coating is prepared by adding a film forming agent, a solvent, an auxiliary agent, an ultraviolet ray absorbing agent and pigment and a filler in order into a plastic tank, stirring the materials for 8-10 min until the materials are fully mixed, stirring the mixture at a speed of 1500 r / min for 25-28 min to fully disperse the mixture, adding a coalescing agent, performing high-speed dispersion for 3-5 min to obtain a dispersion system, adding a mixed solvent including acetone and ethyl acetate in a mass ratio of 1:1 to adjust viscosity, adding a sodium hydroxide solution to adjust the pH value to be 8-9, and fully mixing the mixture to obtain the waterproof coating. The film forming agent is adopted as an important raw material of the coating after the film forming agent is modified, and tensile strength and hardness of film of the film forming agent are significantly improved, and therefore the prepared coating has good weatherability and waterproofness under outdoor conditions and has reflective insulation and decoration functions. A preparing process of the coating is simple.

Owner:南宁马瑞娜装饰工程有限公司

Interior wall environment-friendly coating taking dry ferment as raw material and preparation method thereof

The invention discloses an interior wall environment-friendly coating taking casein as a raw material and a preparation method thereof. The interior wall environment-friendly coating is characterizedin that the raw material comprises a casein solution, kaolin, limestone powder, titanium dioxide and methyl cellulose, and the interior wall environment-friendly coating taking casein as the raw material is obtained after the raw materials are mixed, homogenized, dispersed and subjected to vacuum defoaming. The interior wall environment-friendly coating is simple in formula and does not contain toxic substances such as formaldehyde, ammonia and benzene and achieves zero emission of volatile organic compounds and is healthy and environment-friendly and meets certain flexibility and has quick-drying property and brushability, reduces the cost of the interior wall coating and can be directly applied to new cement and lime walls and humid environments with various slightly corrosive gases andis good in decorative effect, easy to brush and high in durability.

Owner:陕西卓萌商贸有限责任公司

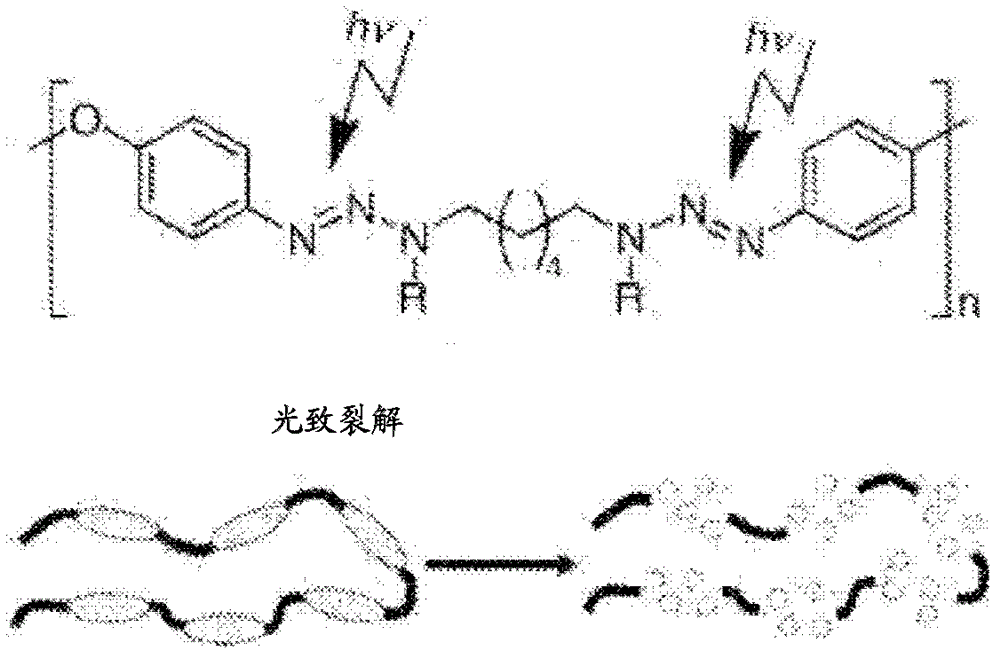

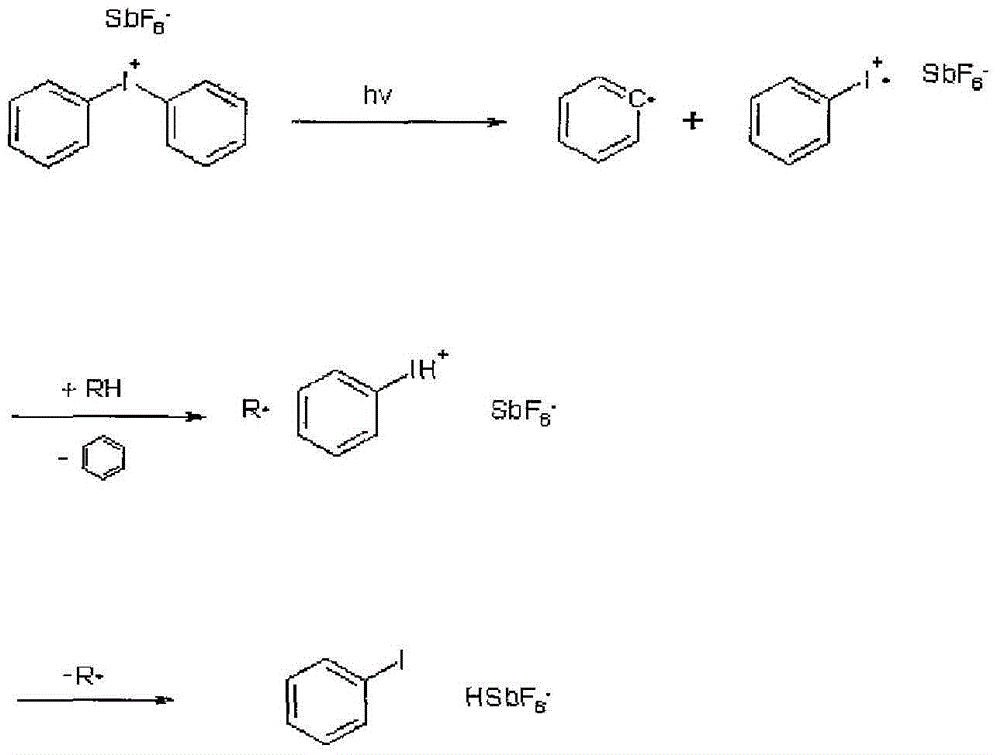

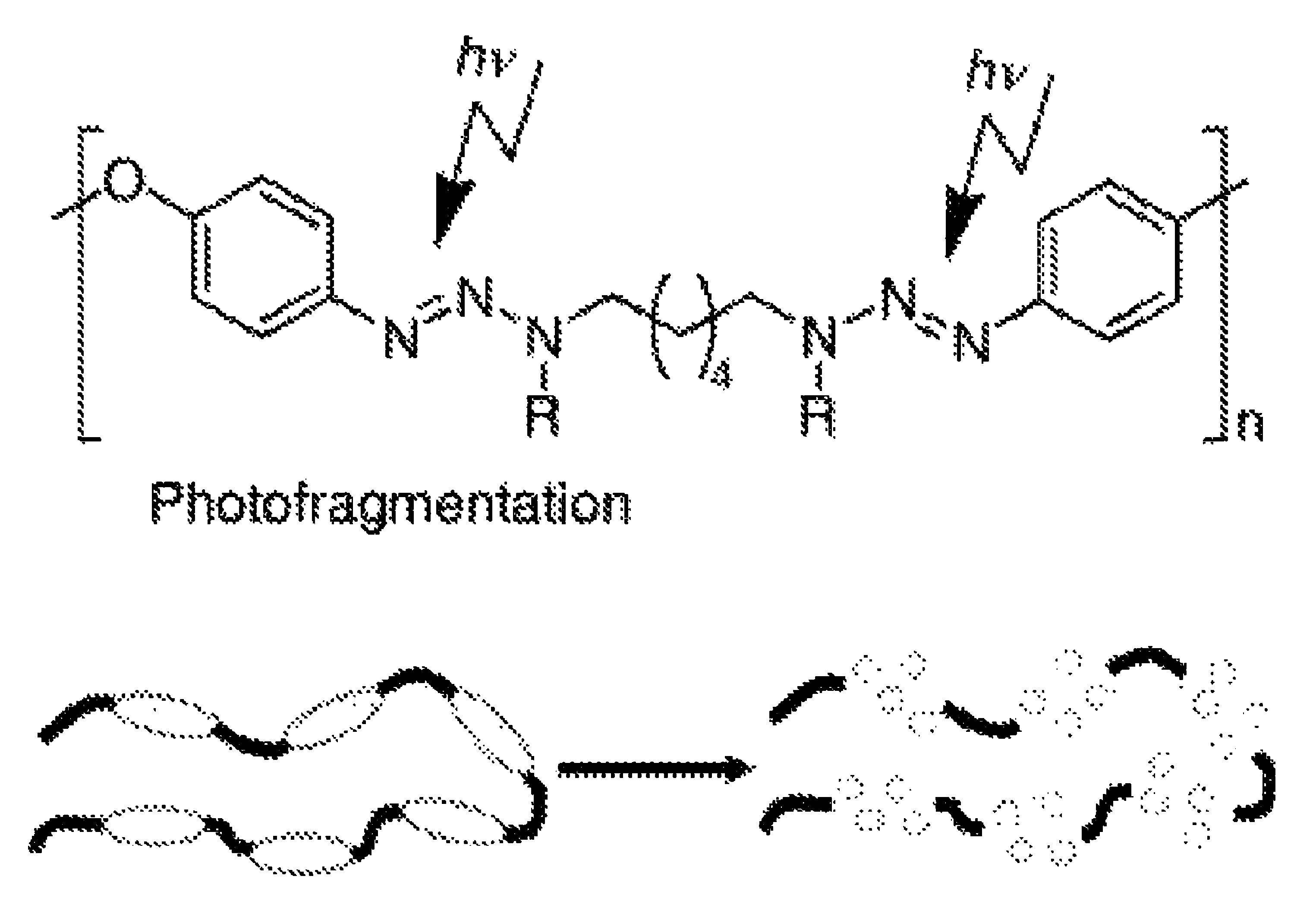

Method for protecting aircraft surfaces from contamination and/or icing by insect residues, application device therefor and aircraft

Method of protecting a part of a surface of an aircraft against contamination with insect residues and / or against icing, comprising the following steps: b) coating the part of the surface to be protected with a coating that can, within a period of ≰3 hours from take-off of the aircraft and in normal flying conditions, reduce the adhesion to the part of the surface to be protected until detachment occurs on the basis of (i) temperature change and / or (ii) UV radiation and / or (iii) addition of a decomposing component and / or (iv) difference in air humidity, b) exposing the part of the surface to be protected to (i) a temperature change and / or (ii) UV irradiation (iii) and / or addition of a decomposing component and / or (iv) a difference in air humidity, so that the coating together with any contaminants and / or icing thereon detaches.

Owner:AIRBUS OPERATIONS GMBH

Cheese mixed linseed oil natural paint and preparation method thereof

ActiveCN108003788BNot releasedReduce pressure on environmental protectionCasein coatingsHazardous substancePreservative

The invention discloses a cheese mixed linseed oil natural coating and a preparation method thereof. The coating is prepared from the following components in part by weight: 300 to 400 parts of activated cheese, 300 to 400 parts of emulsified linseed oil, 10 to 30 parts of emulsifier, 5 to 10 parts of wetting agent, 1 to 4 parts of preservative, 150 to 300 parts of water, and 0 to 1490 parts of other additives. Waste water, waste residue and a coating dry film produced by the coating production can be degraded, and environmental protection pressure can be reduced. The coating dry film can alsoabsorb formaldehyde and purify indoor air; the coating dry film releases no harmful substances.

Owner:德爱威(中国)有限公司

Cheese mixed linseed oil natural coating and preparation method thereof

ActiveCN108003788ANot releasedReduce pressure on environmental protectionCasein coatingsHazardous substancePreservative

The invention discloses a cheese mixed linseed oil natural coating and a preparation method thereof. The coating is prepared from the following components in part by weight: 300 to 400 parts of activated cheese, 300 to 400 parts of emulsified linseed oil, 10 to 30 parts of emulsifier, 5 to 10 parts of wetting agent, 1 to 4 parts of preservative, 150 to 300 parts of water, and 0 to 1490 parts of other additives. Waste water, waste residue and a coating dry film produced by the coating production can be degraded, and environmental protection pressure can be reduced. The coating dry film can alsoabsorb formaldehyde and purify indoor air; the coating dry film releases no harmful substances.

Owner:德爱威(中国)有限公司

Leather coloring technology

InactiveCN108913033AChange the dyeing method of single coloringColoring widely adaptedShellac coatingsCasein coatingsEngineeringSingle effect

The invention discloses leather coloring technology. According to the leather coloring technology, a plate with patters is used for spraying of colorful patterns onto leather surfaces, wherein the plate is prepared through clamping of natural flowers, grass, tree leaves, or plants by two layers of grids. Color and artistic effects are achieved; a conventional leather coloring single effect dying method is changed; the leather coloring technology is widely used for coloring of different kinds of leather, the obtained leather surfaces are bright and smooth, and possess excellent air permeability; the prepared colorful leather possesses natural artistic effects, is beautiful, is excellent in practicability, and possesses dry and wet rubbing resistance, water resistance, sunscreen effect, andinsect resistance.

Owner:王皓平

A kind of antistatic and antibacterial chitosan-casein composite leather finishing agent and preparation method thereof

ActiveCN108342111BImprove stabilitySimple methodAntifouling/underwater paintsCasein coatingsPolymer scienceNatural product

The invention provides a preparation method of an anti-static anti-bacterial chitosan-casein composite leather finishing agent. The preparation method of the anti-static anti-bacterial chitosan-caseincomposite leather finishing agent includes the following steps of 1, dissolving chitosan; 2, dissolving casein; 3, preparing the anti-static anti-bacterial chitosan-casein composite leather finishingagent. Raw materials adopted in the preparation method are biodegradable; a composite technology is adopted, so that the preparation method is simple, the stability of products is good, the preparedanti-static anti-bacterial chitosan-casein composite leather finishing agent is a natural-product-based leather finishing agent with two functions of preventing static and bacteria.

Owner:SHAANXI UNIV OF SCI & TECH

Sealing Composition

A sealant composition for the sealing of a punctured tyre including a liquid carrier, one or more viscosity and suspending agents, one or more fillers and sealants, and one or more polyacrylates.

Owner:TRYDEL RES PTY LTD

Conversion coating for magnesium, beryllium, and their alloys and articles thereof

InactiveUS20110120877A1Easily accept applied coatingMore corrosion resistant surfaceAnodisationCasein coatingsChromate conversion coatingConversion coating

I provide a non-toxic protein and protein compound conversion coated metal article, a painted or plated non-toxic protein and protein compound conversion coated metal article, the aqueous coating solution to provide the in-situ conversion protective coating, and a process of preparing the article. The article is a metal selected from the group consisting of magnesium, magnesium alloy, beryllium and beryllium alloy. The solution has a pH of 3.0 to 12.0 and preferably 4.0 to 10.0 and a protein and protein compound concentration of 0.1 to 10% by weight and the protein and protein compound have a molecular mass of 16,700 to 1,000,000.

Owner:SAN FU CHEM CO LTD

Antibacterial casein-based nano ZNO composite leather finishing agent and preparation method thereof

ActiveCN104830231BImprove antibacterial propertiesCasein coatingsLeather surface finishingWater bathsZno nanoparticles

Owner:广州麦吉高分子新材料科技有限公司

Method for protecting the surface of an aircraft against contamination with insect residues and/or icing

ActiveUS9555901B2Efficient removalReduce adhesionAntifouling/underwater paintsRadiation applicationsAtmospheric sciencesBiology

A method of protecting a part of a surface of an aircraft against contamination with insect residues and / or against icing is described. The method includes the following steps:a) coating the part of the surface to be protected with a coating that can, within a period of ≦3 hours from take-off of the aircraft and in normal flying conditions, reduce the adhesion to the part of the surface to be protected until detachment occurs on the basis of (i) temperature change and / or (ii) UV radiation and / or (iii) addition of a decomposing component and / or (iv) difference in air humidity, andb) exposing the part of the surface to be protected to (i) a temperature change and / or (ii) UV irradiation (iii) and / or addition of a decomposing component and / or (iv) a difference in air humidity, so that the coating together with any contaminants and / or icing thereon detaches.

Owner:AIRBUS OPERATIONS GMBH

Solar thermal-insulation and water-proof coating

InactiveCN108300307AStrong adhesionImprove thermal conductivityFireproof paintsCasein coatingsThermal energyButyl acetate

The invention relates to a solar thermal-insulation and water-proof coating. The coating is prepared from components in parts by weight as follows: 44-87 parts of a film-forming agent, 28-35 parts ofacrylic resin with concentration being 48%-53%, 1.0-2.4 parts of carbon black, 1.1-1.8 parts of chromium oxide green, 8-10 parts of methyl isobutyl ketone, 13-25 parts of a coalescing agent, 4-9 partsof enamel black, 44-63 parts of a light absorption agent, 5-10 parts of organobentonite, 0.1 parts of silicone oil with concentration being 0.5%-1.5%, 23-47 parts of a solvent, 4-8 parts of ferrimanganic black pigment, 6-23 parts of an auxiliary, 8-10 parts of butyl acetate and 6-12 parts of organobentonite. The coating has the advantages of excellent weather fastness and light and color retention performance, is mainly applied to conversion of solar energy into thermal energy, and is particularly suitable for the fields such as a solar water heater, a greenhouse and the like.

Owner:JIANGSU SHUANGNENG SOLAR ENERGY

Anti-ultraviolet high-flame-retardant yacht leather

InactiveCN106366918AImprove securityEffective UV resistanceFireproof paintsWaterborne vesselsBenzoic acidHigh carbon

The invention provides anti-ultraviolet high-flame-retardant yacht leather comprising a leather basic layer and a finishing agent coated on the leather basic layer. The leather basic layer is non-woven cloth obtained after sizing. The finishing agent is prepared from acid nigrosine crystals, pupa casein, dioctyl isophthalate, nipagin, borax, ammonia water, water, carbon black, benzoic acid high-carbon alcohol ester, dimethyl aminophenol octyl benzoate, 4-tert-butyl-4'-methoxy-dibenzoylmethane, cetanol and tris(2,3-dibromopropyl)phosphate. The leather can be applied to a yacht, and has effective anti-ultraviolet capacity and excellent ultraviolet shielding performance, and accordingly a greased leather sample can be endowed with a good ultraviolet shielding function. Meanwhile, the leather has a good flame-retardant effect, cannot be combusted easily after making contact with open fire, and effectively improves use safety of the yacht.

Owner:YANGZHOU DERWINS PLASTICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com