Solar selective heat-absorbing coating

A heat-absorbing coating and selective technology, which is applied in the field of heat-absorbing materials, can solve the problems of high cost, complicated process flow, and high requirements, and achieve the effects of reducing preparation costs, increasing pleochroism, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

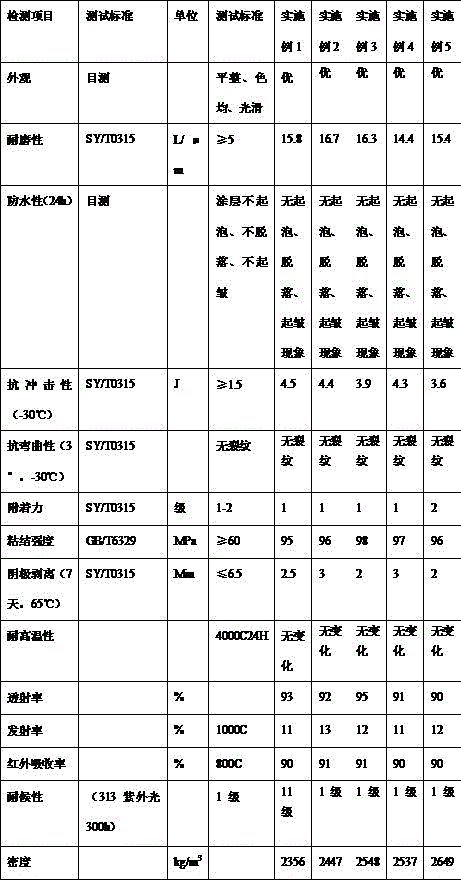

Examples

Embodiment 1

[0031] A kind of solar energy selective heat-absorbing paint, raw material is:

[0032] Film-forming agent: modified casein-gelatin 50kg;

[0033] Film-forming aids: propylene glycol butyl ether 4kg, propylene glycol methyl ether acetate 6kg;

[0034] Light absorbing agent: mix 15kg of cobalt blue powder, 12kg of manganese oxide powder and 8kg of enamel black to make black;

[0035] Solvent: acetic acid 6kg, anhydrous butyl acetate 8kg, glycerol 6kg;

[0036] Auxiliaries are plasticizers, coupling agents, leveling agents, wetting agents and defoamers, wherein,

[0037] Plasticizer: dibutyl phthalate 2kg;

[0038] Coupling agent: silane coupling agent 1kg, titanate coupling agent 2kg;

[0039]Leveling agent: EFKA35702kg, EFKA35801kg for uniform mixing;

[0040] Wetting agent: polysiloxane 2kg;

[0041] Defoamer: polyoxyethylene oxypropylene glycerin 1kg.

[0042] The steps of preparing the solar energy selective heat-absorbing coating according to the above-mentioned raw...

Embodiment 2

[0046] A kind of solar energy selective heat-absorbing paint, raw material is:

[0047] Film-forming agent: modified casein-gelatin 100kg;

[0048] Film-forming aids: propylene glycol butyl ether 10kg, propylene glycol methyl ether acetate 10kg, propylene glycol phenyl ether 10kg;

[0049] Light absorbing agent: Use 10kg of cobalt blue powder, 20kg of manganese oxide powder and 25kg of organic carbon black to make black;

[0050] Solvent: 15kg of glycerol, 15kg of tetrahydrofuran-oxypropylene copolymerized glycol and 25kg of polyurethane polyether polyol;

[0051] Auxiliaries are plasticizers, coupling agents, leveling agents, wetting agents and defoamers, wherein,

[0052] Plasticizer: dibutyl phthalate 3kg;

[0053] Coupling agent: aluminate coupling agent 2kg;

[0054] Leveling agent: YCK-13605kg;

[0055] Wetting agent: polyether modified polydimethylpolysiloxane 2kg;

[0056] Defoamer: polyoxyethylene polyoxypropylene pentaerythritol ether 3kg;

[0057] The steps o...

Embodiment 3

[0061] A kind of solar energy selective heat-absorbing paint, raw material is:

[0062] Film-forming agent: modified casein-gelatin 80kg;

[0063] Film-forming aids: propylene glycol methyl ether acetate 10kg, propylene glycol phenyl ether 5kg, benzyl alcohol 10kg;

[0064] Light absorbing agent: Use 18kg of chromium oxide green powder, 12kg of selenium cadmium sulfide powder, and 20kg of iron oxide red powder to make red;

[0065] Solvent: acetic acid 20kg, and polyurethane polyether polyol 20kg;

[0066] Auxiliaries are plasticizers, coupling agents, leveling agents, wetting agents and defoamers, wherein,

[0067] Plasticizer: dibutyl phthalate 2kg;

[0068] Coupling agent: a mixture of 2 kg of phosphate coupling agent and 2 kg of borate coupling agent;

[0069] Leveling agent: mix BYK-3332kg and TEGOGlide1002kg;

[0070] Wetting agent: polyester modified polydimethylsiloxane 3kg;

[0071] Defoamer: Polyoxypropylene 2kg.

[0072] The steps of preparing the solar energ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com