Coating compositions

A composition and coating technology, applied in paper coatings, starch coatings, casein coatings and other directions, can solve problems such as influence, inability to coat coating compositions, unfavorable stability, etc., and achieve the effect of reducing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0013] According to one embodiment of the invention, the coating composition comprises pigments. In one embodiment, such pigments are water insoluble pigments or pigments that are sparingly soluble in water. In another embodiment, such pigments are white pigments or mixtures of white pigments. There is no particular restriction on the chemical composition of the pigment, so long as its rheological properties when dispersed in the coating formulation make the coating solution coatable in the designed coating machine. The rheological properties here refer to the viscosity, solids content and thixotropic index of the coating solution.

[0014] In one embodiment, the pigment or pigment mixture is in the form of a pigment paste or pigment dispersion. In one embodiment of the invention, the pigment is present in the composition in an amount from about 10% to about 95%, based on the total dry weight of the coating composition. In another embodiment, the total amount of pigment is ...

Embodiment 1

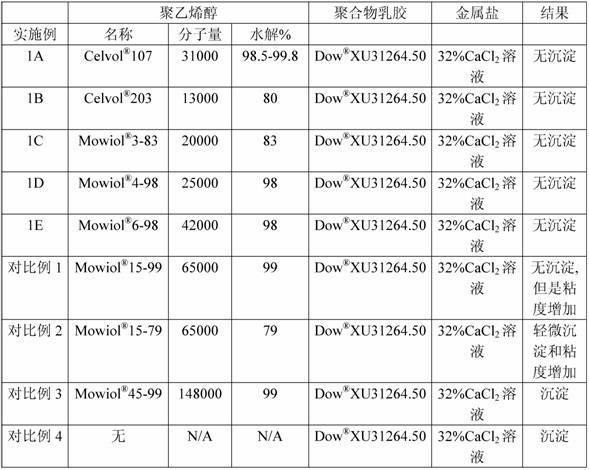

[0056]Embodiment 1: the preparation of the polymer complex containing metal

[0057] Different polyvinyl alcohol (Celvol ? or Mowiol ? ) powder precooked to convert the purchased powder into a PVA solution. The precooking was carried out at 90-105° C. with stirring for 1 hour until there were no solid particles in the solution.

[0058] First, 10 parts (dry weight) of the polymer latex trade name Dow ? XU31264.50 was charged into the mixing tank and stirred with the PVA solution (3 parts dry weight). After 30 minutes, will contain 32% salt (CaCl 2 ) solution (10 parts dry weight) was slowly added to the mixture under vigorous shear stirring. A metal-containing polymer complex is thus obtained. Metal-containing polymer complexes prepared from different types of polyvinyl alcohols were compared based on their ability to remain stable and not precipitate after addition to metal salt solutions. The results are shown in Table 1.

[0059] Table 1

[0060]

Embodiment 2

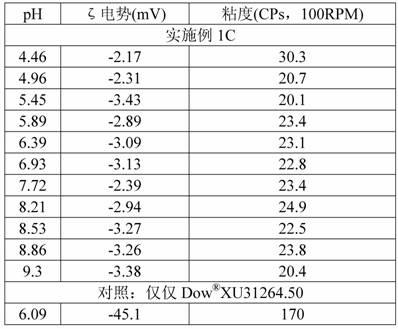

[0061] Example 2: Zeta Potential of Metal-Containing Polymer Latex at Different pH

[0062] The zeta potential of the metal-containing polymer complex of Example 1C of Example 1 was measured at different pH using a zeta classifier (Nano Series) model ZEN3600 supplied by Malvern Instruments. Viscosity was also measured in cps at 100 RPM using a 2# Brookfield spindle. The pH is adjusted by NaOH or HCI solution. The results are shown in Table 2.

[0063] These results demonstrate that in the metal-containing polymer latex obtained according to Example 1C, the zeta potential obtained is relatively constant over a wide pH range. Use polymer latex adhesive (Dow only ? XU31264.50) as a comparative control.

[0064] Table 2

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com