Cheese mixed linseed oil natural paint and preparation method thereof

A technology of linseed oil and cheese, applied in the field of coatings, can solve problems such as waste of food resources, and achieve the effect of reducing environmental protection pressure and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

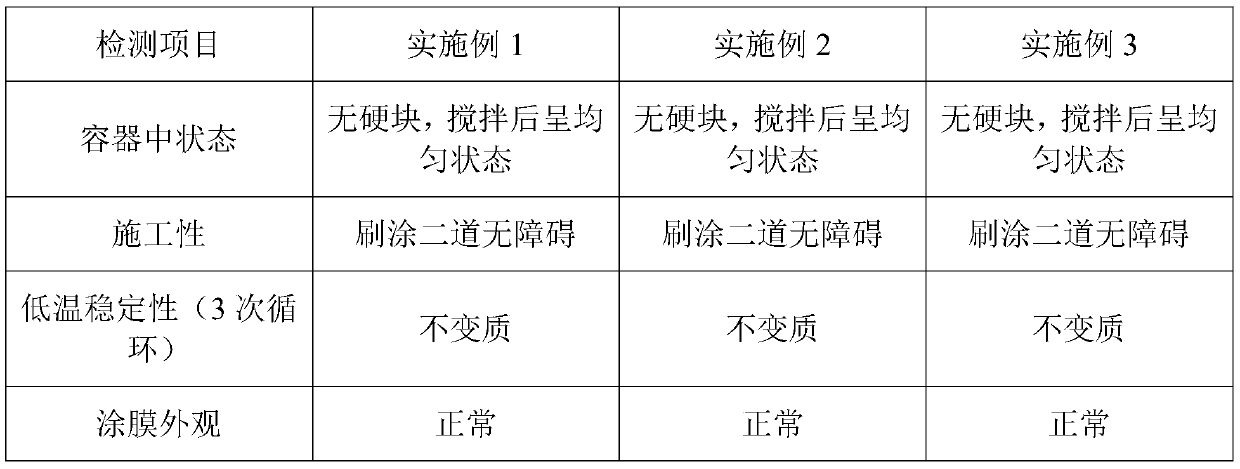

Examples

preparation example Construction

[0039] The second aspect of the present invention provides the preparation method of above-mentioned cheese mixed linseed oil natural coating, and this preparation method comprises:

[0040] The activated cheese, the emulsified linseed oil, emulsifier, wetting agent, preservative, water and other optional additives are uniformly mixed to prepare the cheese mixed linseed oil natural coating.

[0041] As a preferred solution, add the following components after metering: add part of deionized water, part of emulsified linseed oil, part of activated cheese, emulsifier, part of defoamer to the dispersion tank and stir evenly; then add kaolin, calcium carbonate, Titanium dioxide, anti-sedimentation agent, some preservatives, disperse at high speed for 20 minutes until the fineness is less than 60um; then add the remaining activated cheese, the remaining defoamer, and wetting agent to disperse evenly; finally add the remaining emulsified linseed oil to disperse evenly, and add matting...

Embodiment 1

[0050] This embodiment provides a natural cheese mixed linseed oil coating, the specific preparation method is as follows:

[0051] (1) Preparation of activated cheese: 160 parts of casein, 600 parts of deionized water, and 0.8 parts of potassium sorbate are added to the mixing tank, the disperser of the mixing tank is turned on, and the rotating speed is kept at 1400 rpm, 80 parts The mass concentration of 20% sodium hydroxide aqueous solution is premixed with 300 parts of deionized water and then added, stirred for 20 minutes to obtain activated cheese;

[0052] (2) Preparation of emulsified linseed oil: 700 parts of deionized water are added to the emulsification tank, 20 parts of emulsifier and 5 parts of potassium sorbate are added in sequence, stirred evenly at high speed, and 350 parts of linseed oil is slowly added, Stir at high speed for 20 minutes to obtain emulsified linseed oil;

[0053](3) Preparation of cheese mixed linseed oil natural coating: 200 parts of deio...

Embodiment 2

[0055] This embodiment provides a natural cheese mixed linseed oil coating, the specific preparation method is as follows:

[0056] Preparation of activated cheese: Add 160 parts of casein, 600 parts of deionized water, and 0.8 parts of potassium sorbate into the mixing tank, turn on the disperser of the mixing tank, keep the speed at 1400 rpm, and the mass concentration of 80 parts 20% sodium hydroxide aqueous solution is premixed with 300 parts of deionized water and then added, stirred for 20 minutes to obtain activated cheese;

[0057] Preparation of emulsified linseed oil: Add 700 parts of deionized water into the emulsification tank, add 20 parts of emulsifier and 5 parts of potassium sorbate in sequence, stir evenly at high speed, slowly add 350 parts of linseed oil, and stir at high speed for 20 Minutes to obtain emulsified linseed oil;

[0058] Preparation of cheese mixed linseed oil natural coating: 200 parts of deionized water, 150 parts of emulsified linseed oil, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com