Moisturizing dust suppressant for road dust and preparation method thereof

A dust suppressant and wet-type technology, applied in chemical instruments and methods, other chemical processes, protein coatings, etc., can solve the problems of secondary pollution, low content, and reduced frictional resistance on the road surface, so as to prevent secondary pollution Raised effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

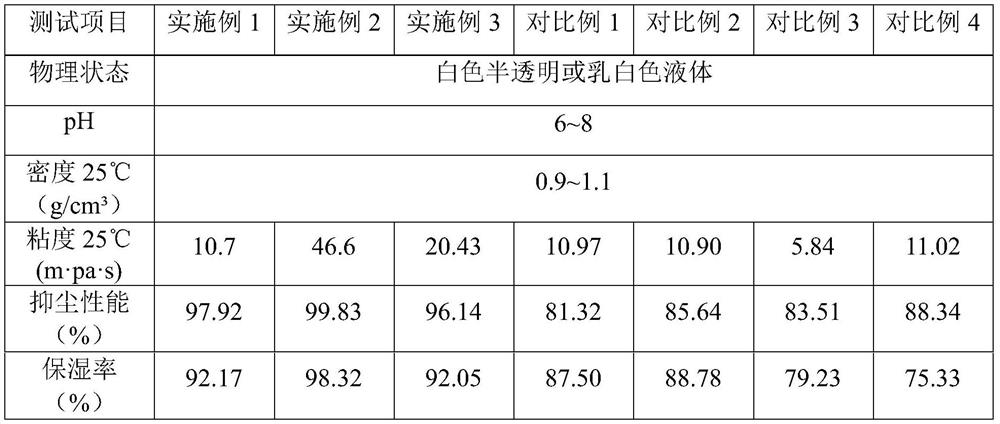

Examples

Embodiment 1

[0035] A moisturizing dust suppressant for road dust, consisting of the following components in mass percentage:

[0036] Mixed aqueous solution, in which acetyl tributyl citrate is 0.5%, aqueous stearic acid emulsion is 3%, and soluble starch is 0.1%;

[0037] Binder chitosan: 0.1%;

[0038] Humectant seaweed biological sugar gum: 0.1%;

[0039] Surfactant fatty alcohol polyoxyalkyl ether: 0.1%.

[0040] The preparation method of above-mentioned dust suppressant, comprises the steps:

[0041] (1) Weigh each raw material according to the mass percentage, divide the water into three parts A, B, and C, heat A to 70°C, and heat B and C to 40°C; wherein, the mass ratio of A:B:C is 1:1:1;

[0042] (2) Mix chitosan with water in part A, heat and stir at 100 rpm / min for 30 min, then cool to room temperature to obtain aqueous solution a;

[0043] (3) Acetyl tributyl citrate was mixed with water in part B, and aqueous stearic acid emulsion and soluble starch were added in sequence...

Embodiment 2

[0047] A moisturizing dust suppressant for road dust, consisting of the following components in mass percentage:

[0048] Mixed aqueous solution, wherein acetyl tributyl citrate is 1%, aqueous stearic acid emulsion is 4%, and soluble starch is 3%;

[0049] Binder sodium caseinate: 10%;

[0050] Humectant glycerin polyoxyethylene ether: 5%;

[0051] Surfactant fatty alcohol polyoxyalkyl ether: 1%.

[0052] The preparation method of above-mentioned dust suppressant, comprises the steps:

[0053] (1) Weigh each raw material according to the mass percentage, divide the water into three parts A, B, and C, heat A to 90°C, and heat B and C to 50°C; wherein, the mass ratio of A:B:C is 1:0.5:0.5;

[0054] (2) Mix sodium caseinate with water in part A, heat and stir at 300 rpm / min for 40 min, then cool to room temperature to obtain aqueous solution a;

[0055] (3) Acetyl tributyl citrate was mixed with water in part B, and aqueous stearic acid emulsion and soluble starch were added...

Embodiment 3

[0059] A moisturizing dust suppressant for road dust, consisting of the following components in mass percentage:

[0060] Mixed aqueous solution, in which acetyl tributyl citrate is 0.5%, aqueous stearic acid emulsion is 3%, and soluble starch is 0.1%;

[0061] Binder sodium caseinate: 0.1%;

[0062] Humectant seaweed biological sugar gum: 0.1%, glycerol polyoxyethylene ether: 0.1%;

[0063] Surfactant fatty alcohol polyoxyalkyl ether: 0.1%.

[0064] The preparation method of above-mentioned dust suppressant, comprises the steps:

[0065] (1) Weigh each raw material according to the mass percentage, divide the water into three parts A, B, and C, heat A to 80°C, and heat B and C to 45°C; wherein, the mass ratio of A:B:C is 1:1:1;

[0066] (2) Chitosan is mixed with water in part A, and after stirring for 30 minutes at a rotating speed of 200 rpm / min, it is cooled to room temperature to obtain aqueous solution a;

[0067] (3) Acetyl tributyl citrate was mixed with water in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com