Process for sealing glass containers, glass containers and coating material

A technology for glass containers and coating agents, applied in the field of coating agents, can solve problems such as insufficient technology and achieve the effect of excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

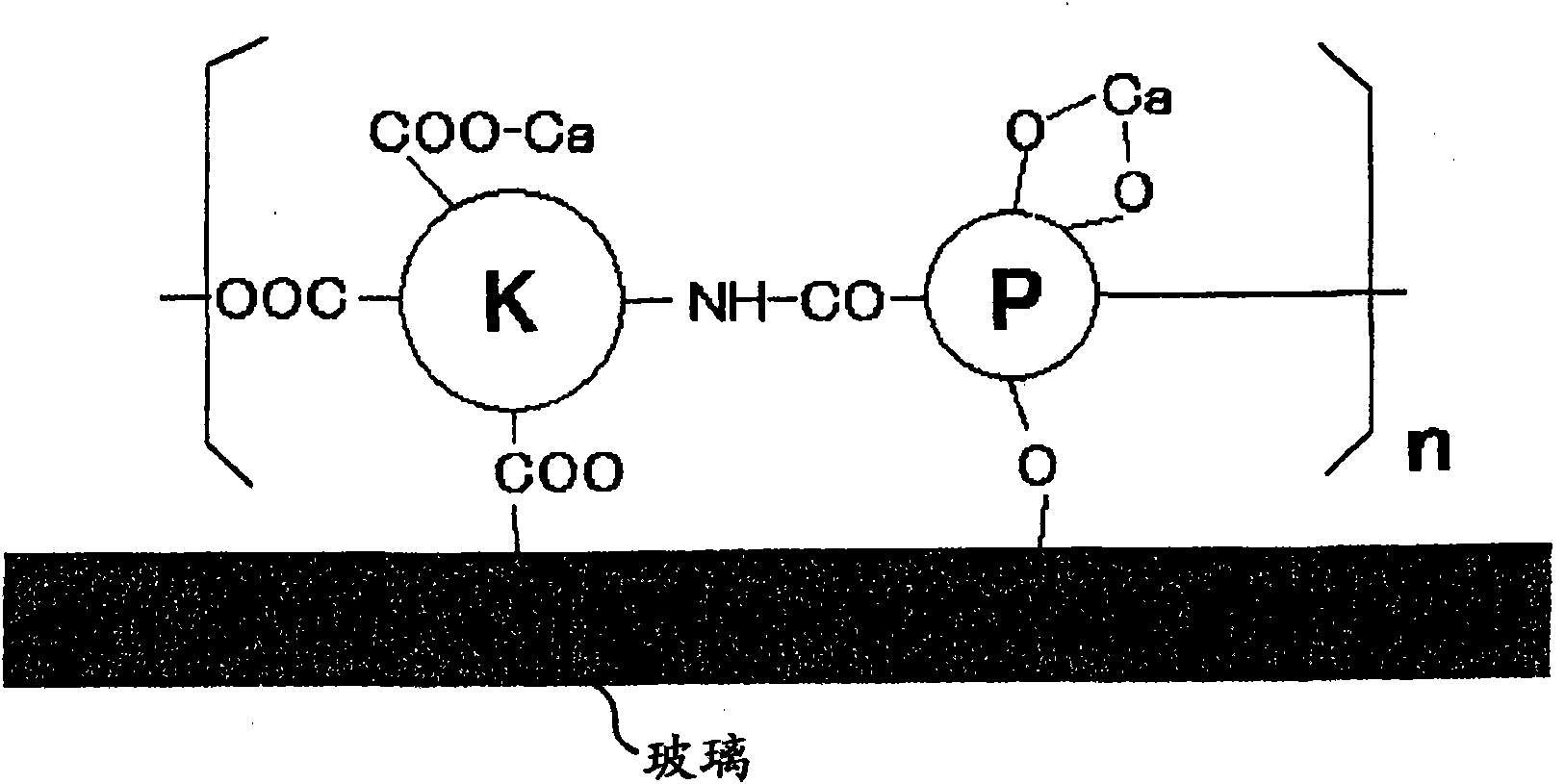

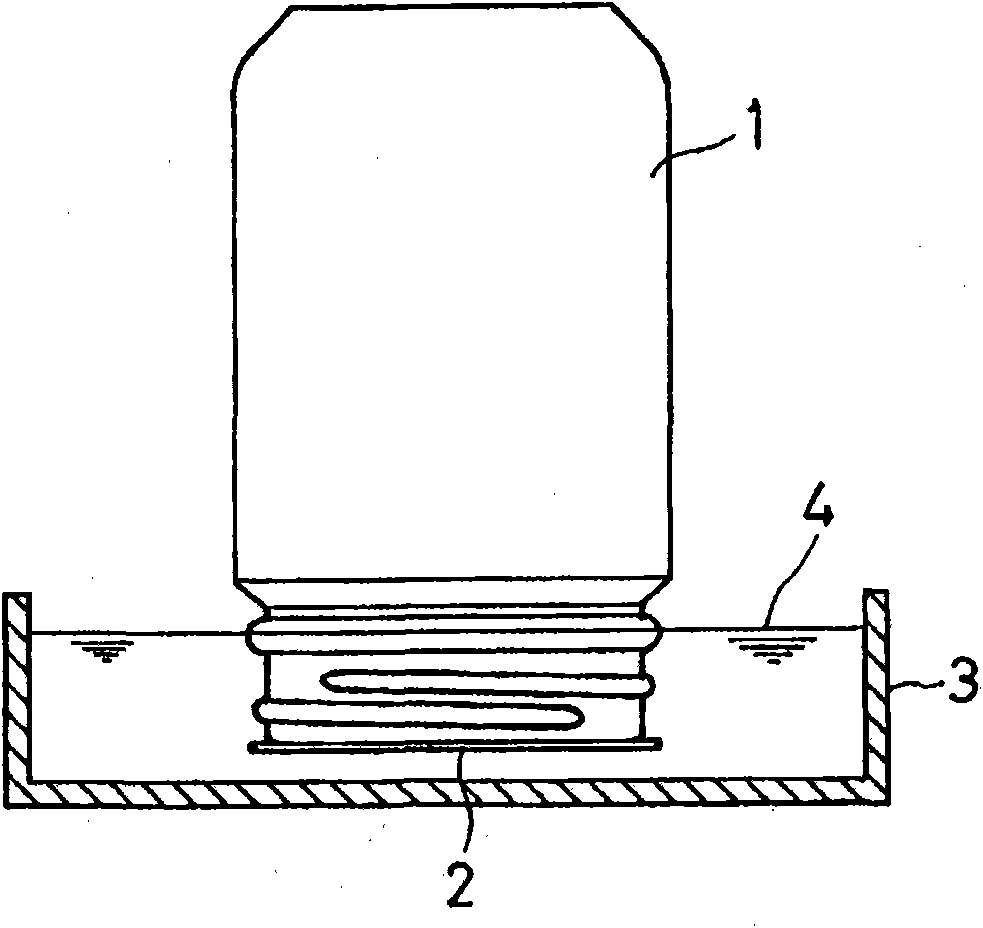

Method used

Image

Examples

Embodiment 1

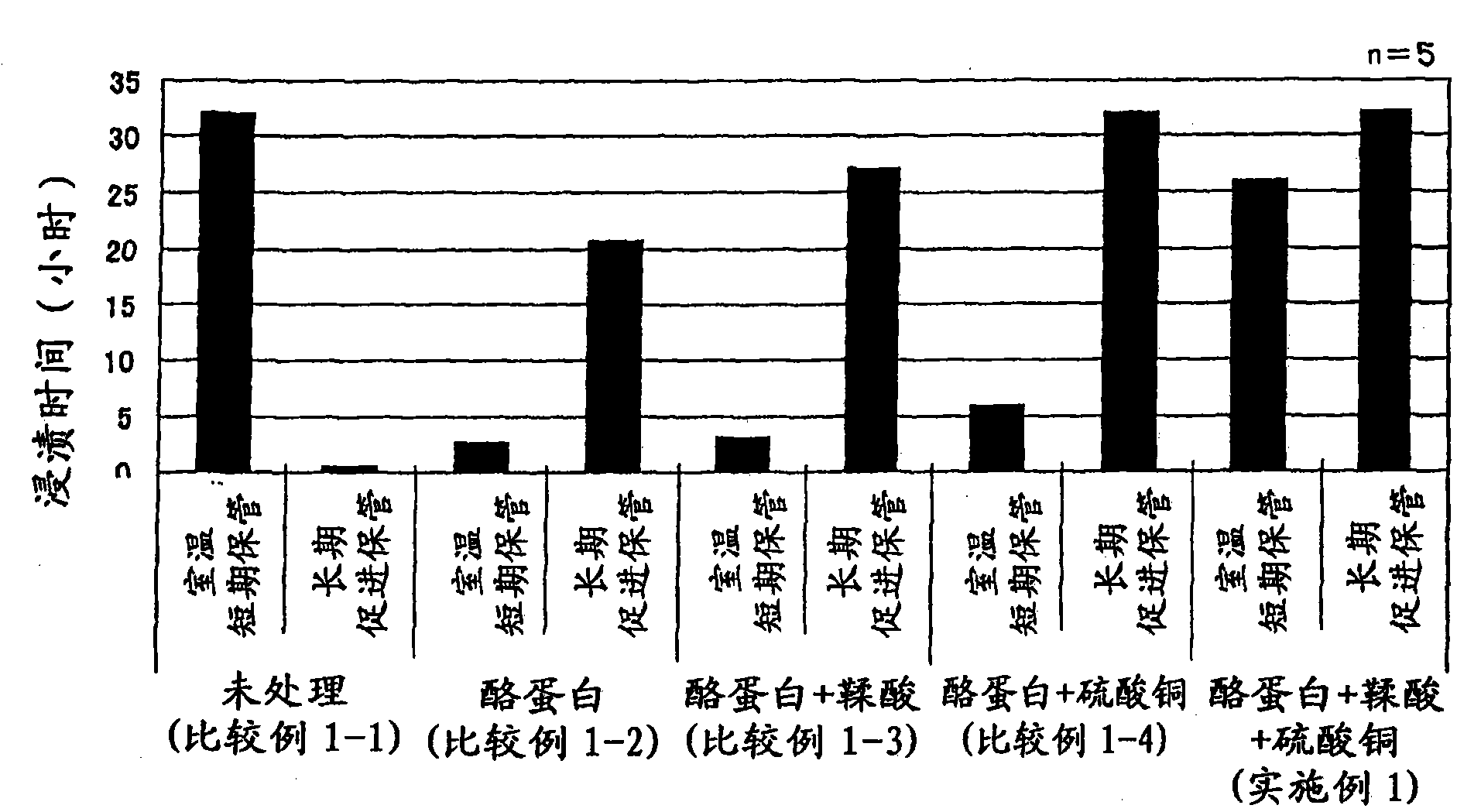

[0073] [Example 1 and corresponding comparative example]

[0074] The following coating agents were applied to produce Example 1 and Comparative Examples 1-2 to 1-4 (coating was not performed in Comparative Example 1-1).

[0075] Embodiment 1: the aqueous solution of casein (0.25wt%), tannic acid (0.05wt%), copper sulfate (0.05wt%), ammoniacal liquor (0.125vol%)

Embodiment 2

[0083] [Example 2 and corresponding comparative example]

[0084] The following coating agents were applied to produce Example 2 and Comparative Examples 2-2 to 2-4 (coating was not performed in Comparative Example 2-1).

[0085] Embodiment 2: the aqueous solution of casein (0.25wt%), tannic acid (0.05wt%), calcium hydroxide (0.025wt%), ammoniacal liquor (0.025vol%)

Embodiment 3

[0093] [Example 3 and corresponding comparative example]

[0094] The following coating agents were applied to produce Example 3 and Comparative Examples 3-2 to 3-4 (coating was not performed in Comparative Example 3-1).

[0095] Embodiment 3: the aqueous solution of casein (0.25wt%), tannic acid (0.05wt%), ferric chloride (0.075wt%), ammoniacal liquor (0.025vol%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com